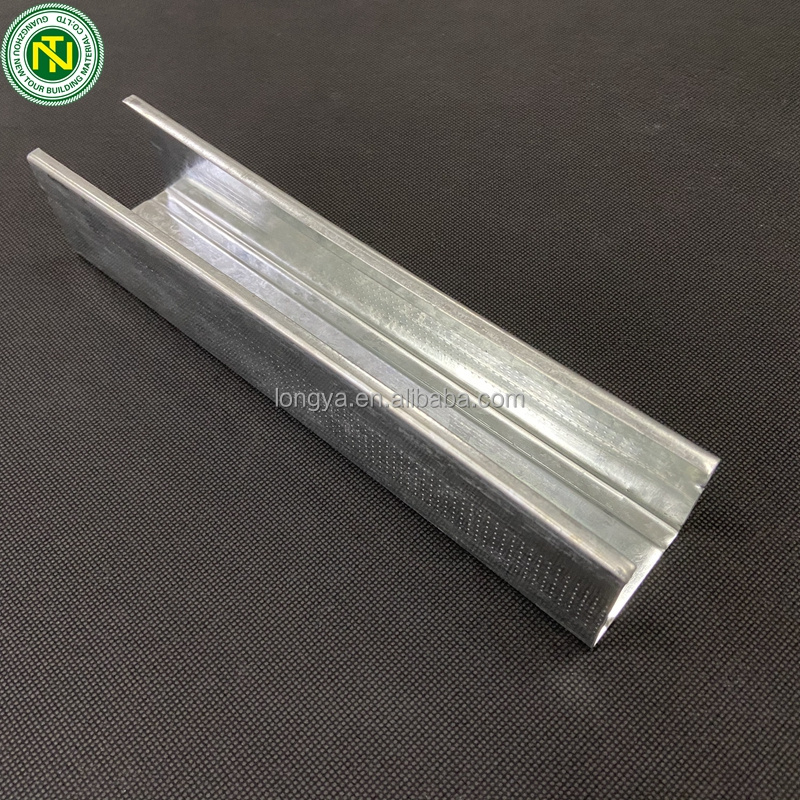

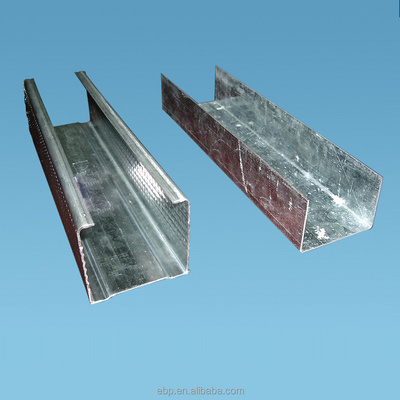

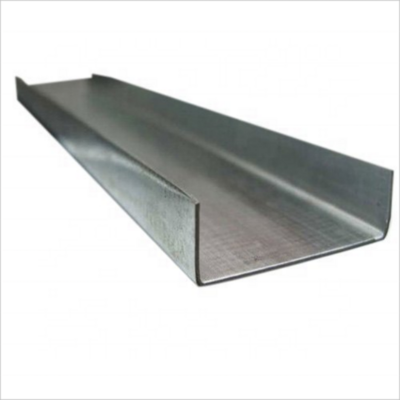

1. Galvanized Metal Frame

a.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

2. Board Material Package Fixed

a.Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b.Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250 mm with screws sinking 0.5 mm under the board face.

c.The expansion seam of about 4 mm between boards should be kept.

d.The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

e.Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.