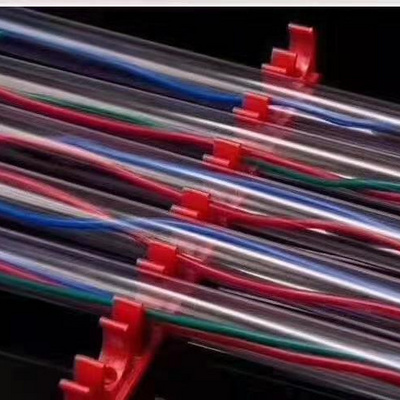

1. The extruder of HDPE pipe line adopt high efficiency screw & barrel, notched feeding cylinder and is equipped with strong water

jacket cooler, which greatly improves its transmission capacity and guarantees high-efficiency extrusion. the gearbox is hardening

teeth gearbox with self-lubrication system. The motor adopt Siemens standard motor and speed controlled by ABB inverter. The

control system adopts Siemens PLC control or button control.