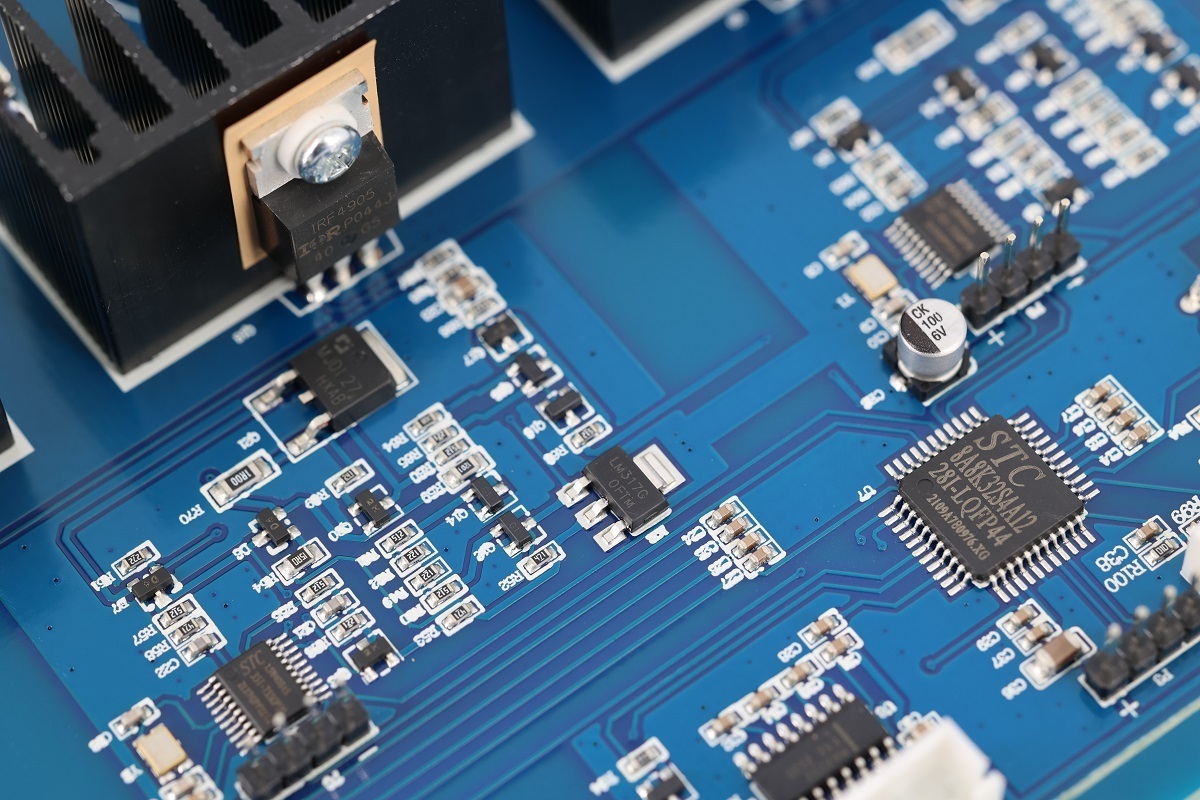

King Field has established long-term and stable cooperate relations with the world's leading communication equipment , aerospace electronics and medical equipment manufacturers.

|

SMT Manufacturing Capability

|

|

|

|

|||

|

Item

|

|

Manufacturing Capability in process

|

Manufacturing Method

|

|||

|

Production size(Min/Max)

|

|

50×50mm / 500×500mm

|

|

|||

|

Production board thickness

|

|

0.2 ~ 4mm

|

|

|||

|

Printing solder paste

|

Support method

|

|

Magnetism fixture, vacuo platform

|

|||

|

|

|

|

Sticking up by vacuo, clamping on both sides ,flexible clamping with sheet, flexible clamping with thick board

|

|||

|

|

Cleaning Method of printing solder paste

|

|

Dry method+ wetting method+ Vacuo method

|

|||

|

|

Accuracy of printing

|

±0.025mm

|

|

|||

|

SPI

|

Repeated accuracy of volume

|

<1% at 3σ

|

|

|||

|

Mounting component

|

Components size

|

0603(Option) L75mm Connector

|

|

|||

|

|

Pitch

|

0.15mm

|

|

|||

|

|

Repeated accuracy

|

±0.01mm

|

|

|||

|

AOI

|

FOV size

|

61×45mm

|

|

|||

|

|

Test speed

|

9150mm²/Sec

|

|

|||

|

3D X-ray

|

Shootingangle

|

0-45

|

|

|||