NaN / 0

new arrival Waste tire recycling rubber processing equipment production line

Get Latest Price

US$ 10300

≥1 Sets

US$ 9800

≥3 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

center

Voltage:

customizable

Power (kW):

132 kW

Product Details

Brief Introduction

The waste tire production line is a production line that reuses waste tires. Through this production line, waste tires can be broken down and converted into rubber particles and steel wires. These products can be reused, for example, to make new tires, rubber products and building materials. In addition, these products can also be used as fuel to generate electricity and heat, further reducing environmental pollution.

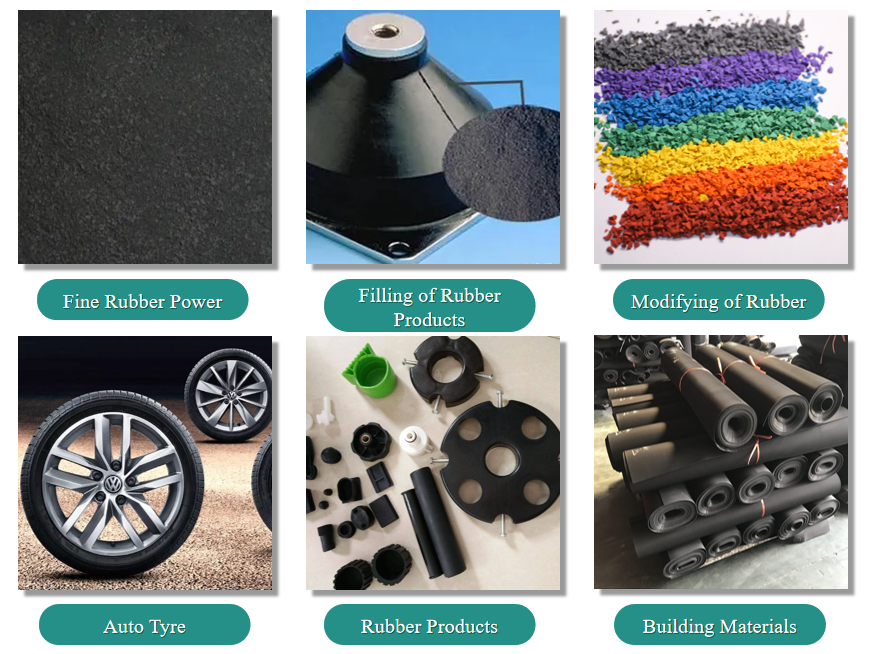

Product Application

8-20 mesh

Mainly used in pavement of track, road cushion layer, base plate, lawn, paving elastic layer, athlectic ground, etc.

30-40 mesh

Mainly used in producing reclaimed rubber and rubber board, modifying rubber power, paving roads, etc.

40-60 mesh

Called fine rubber power, used in filling of rubber products, modifying of plastic, etc.

60-80 mesh

Called refined rubber power, used in automobile tires, rubber products,construction materials and so on.

Rubber particles can be converted into fuel oil by pyrolysis. Pyrolysis is a chemical process that converts rubber particles into

wave fuel oil, gas, and isomeric residue by heating them at high temperatures and cracking them in the absence of oxygen or limited oxygen. It should be noted that the preparation of fuel oil by pyrolysis rubber glume requires professional equipment and processes, and environmental protection and other factors should also be considered. This process is also used in some places to

treat waste rubber products to achieve resource reuse and energy recovery.

wave fuel oil, gas, and isomeric residue by heating them at high temperatures and cracking them in the absence of oxygen or limited oxygen. It should be noted that the preparation of fuel oil by pyrolysis rubber glume requires professional equipment and processes, and environmental protection and other factors should also be considered. This process is also used in some places to

treat waste rubber products to achieve resource reuse and energy recovery.

Products Description

Technological Process

Auto line:Whole tire-remove steel-Shredde to rubber block-Roller mill-Steel wire and rubber particles

Hydraulic wire drawing machine:

The waste tire is brushed to separate the rubber material from the outer layer of the tire.

Tire cutting machine:

The waste tires are cut and decomposed for subsequent processing and reuse.

Tire rim slitting machine:

separation and treatment of scrap tire metal rim.

Wire rolling machine:

the rubber and other materials such as steel wire, fiber, etc.

Dual-shaft shredder:

The effective coarse crushing of waste tires, the tires are broken into block materials.

Cache bin:

Temporary storage of waste tire particles or block materials processed from equipment such as dual-shaft shredder.

Roller grinding machine:

Further crushing and grinding waste tire particles, make its texture more uniform and fine, improve the efficiency and quality of subsequent processing.

Screening machine:

By replacing different specifications of the screen, the size range of particles can be adjusted to meet the requirements of different process or market demand for particle size.

The first stage magnetic separator:

Removes the steel wire or steel cord in the waste tire particles for subsequent processing and utilization.

Second stage magnetic separator:

Further remove metal impurities that may remain in waste tire particles. Although the first stage magnetic separator can remove most of the iron impurities, there may still be some small or difficult to be completely adsorbed metal particles.

Vibrating screen:

The treated waste tire particles are screened and classified according to different particle sizes.

Air circulation cooling system:

Through the circulation of air supply, heat transfer and other ways, the heat is taken away, so as to effectively reduce the temperature of the process equipment and the environment, to ensure the normal operation of the equipment.

Why Choose Us

Certifications

FAQ

Q: How To Choose A Suitable Tire Recycling Line?

A: Please tell us your capacity and the output size, we will recommend you the most suitable tire recycling line.

Q: Can We Get Very Fine Powder From The Recycling Line?

A: Yes, you can get 20-120 mesh fine rubber powder with fine grinder system.

Q: What About The Machine Installation?

A: We will send you installation guidance,commissioning and training when everything is ready on the working site, like power, cable, labors, forklift, etc.

Q: How About the Spare Parts?

A: We provide spare parts at cost price permanently and will give you the spare parts list when you purchase machine.

Q: Will You Test The Machine Before Delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

Hot Searches