2.We will send the instruction book to you to let you install the machine. You can talk with our engineer by video chat or we will send the engineers overseas to help you.

|

Models

|

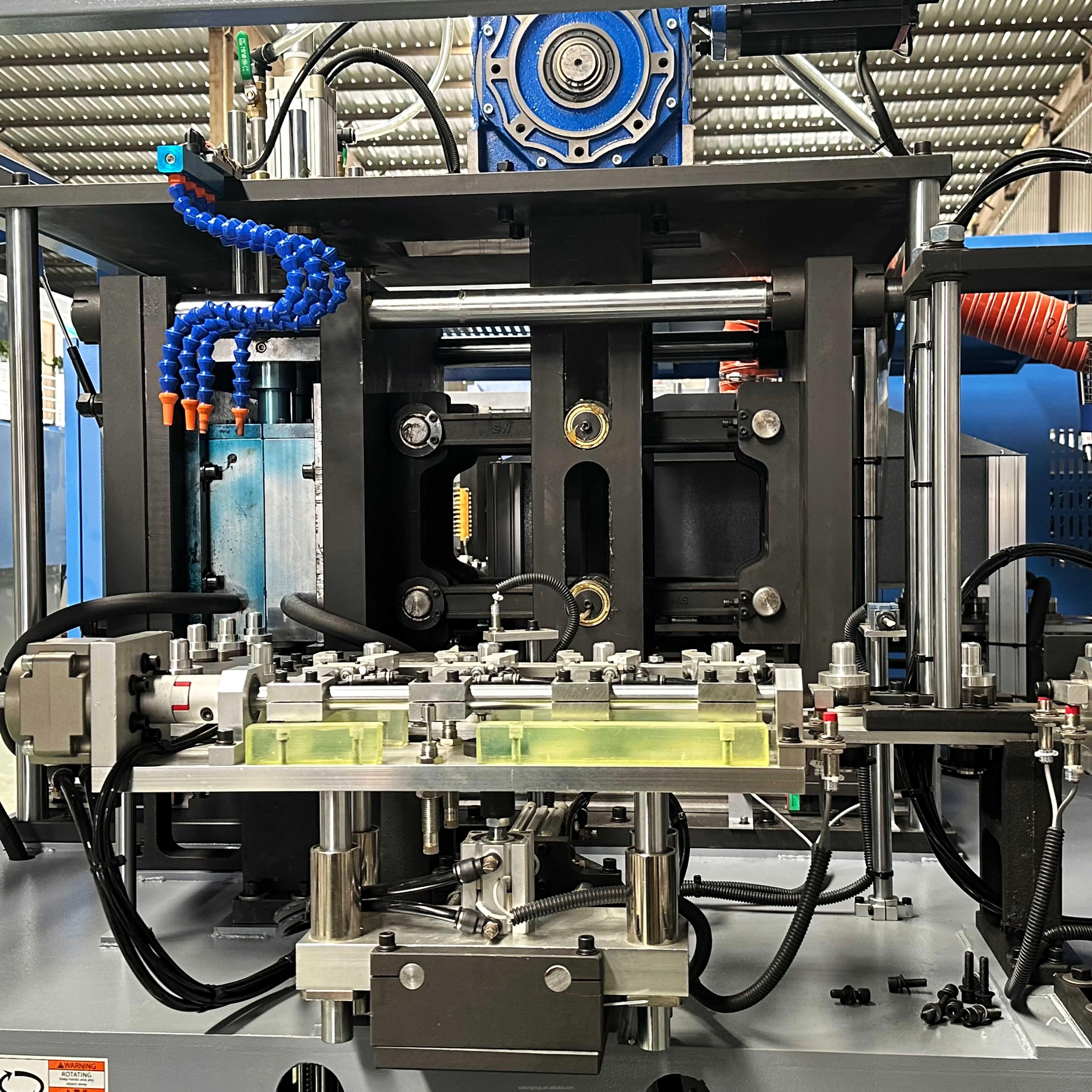

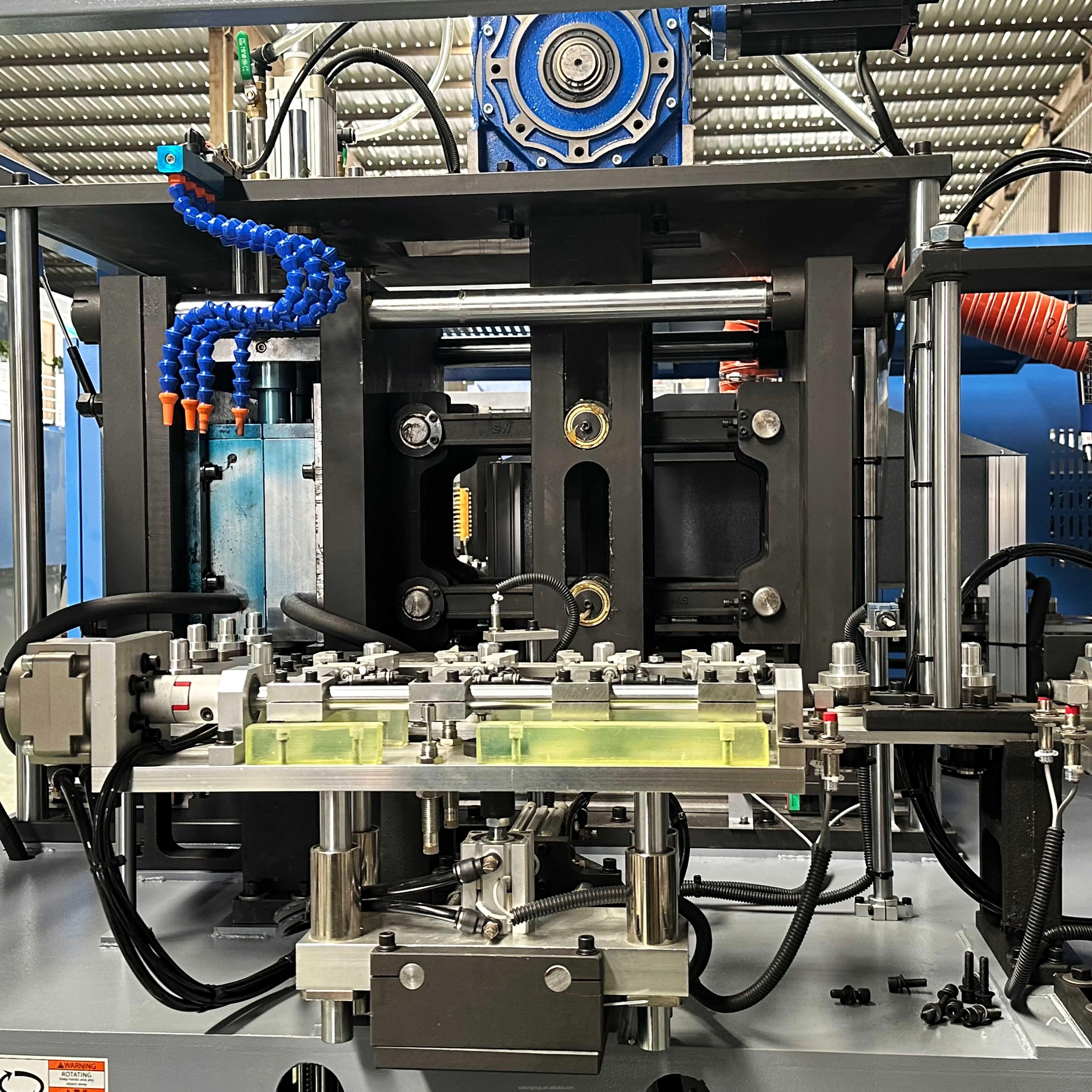

Turbo-4L

|

|

Theoretical Capacity

|

5000-6000BPH

|

|

Mold Cavities

|

4

|

|

Neck Size

|

18-38mm

|

|

Max. Volume

|

2000ml

|

|

Advantages

|

1.Using touch screen, easy to operate, save space.

2.Mold fixed by drawer design, mold changeover can be easily done in half hour.

|

|

Models

|

|

TURBO-4S

|

TURBO-4L

|

TURBO-6S

|

TURBO-6L

|

TURBO-9S

|

|

|

Theoretical Capacity(BPH)

|

|

6,000~7,000

|

5,000~6,000

|

9,000~10,000

|

68000~9,000

|

12,000~13,000

|

|

|

Mold Cavities

|

|

4

|

4

|

6

|

6

|

9

|

|

|

Bottle

|

Neck Size

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

|

|

|

Max. Volume

|

750ml

|

2000ml

|

750ml

|

2000ml

|

750ml

|

|

|

|

Max. Diameter

|

69mm

|

105mm

|

69mm

|

105mm

|

69mm

|

|

|

|

Max. Height

|

240mm

|

330mm

|

240mm

|

330mm

|

240mm

|

|

|

Power

|

Heater qty

|

21pcs

|

32pcs

|

28pcs

|

48pcs

|

42pcs

|

|

|

|

Heating Area

|

3

|

4

|

4

|

6

|

6

|

|

|

|

Heating Power

|

46KW

|

70KW

|

62KW

|

106KW

|

94KW

|

|

|

|

Rated General Power

|

58KW

|

82KW

|

75KW

|

120KW

|

110KW

|

|

|

High Pressure Air Consumption(m3/min)

|

|

3.0

|

3.0

|

5.0

|

5.0

|

8.0

|

|

|

Main Machine Size

|

|

3000*1800*2200mm

|

4200*2100*2400mm

|

4200*2050*2400mm

|

5800*2150*2400mm

|

5800*2100*2400mm

|

|

|

Main Machine Weight

|

|

3200KGS

|

5000KGS

|

5500KGS

|

7800KGS

|

7500KGS

|

|