NaN / 0

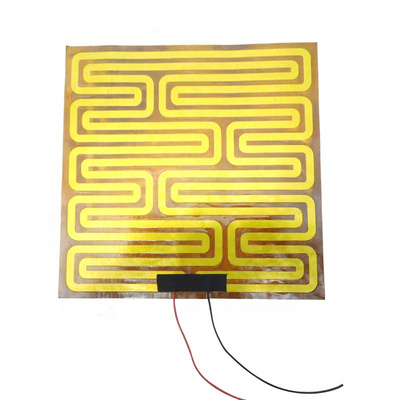

12V electric thin film heater polyimide heating pad for battery

Get Latest Price

US$ 1

≥1000 Pieces

US$ 0.8

≥5000 Pieces

US$ 0.6

≥10000 Pieces

Quick Details

Type:

Flexible Heater

Power Source:

Electric

Voltage:

0-380V

Place of Origin:

Jiangsu, China

Product Details

Order Guide:

1.Please advice us Voltage,Power or Resistance.

2.Size:Length and Width.Please send us drawing if you have.

3.Cable length

4.Other requirements is availble.

Let's talk more if you interest!Contacts at the bottom.

2.Size:Length and Width.Please send us drawing if you have.

3.Cable length

4.Other requirements is availble.

Let's talk more if you interest!Contacts at the bottom.

Product Description

Polyimide thermofoil flexible thin film heater heating pad

The polyimide film PI electrothermal film is a polyimide film as an outer insulator; the metal foil and the metal wire are internal conductive heating bodies, which are formed by heat sealing at high temperature and high pressure. Polyimide film electrothermal film has excellent dielectric strength; excellent electric strength; excellent heat transfer efficiency; excellent resistance stability. This makes it widely applicable to the field of heating and is capable of achieving relatively high temperature control accuracy.

Polyimide is a thin, translucent material, has excellent dielectric strength. In the narrow space or require lighter, heater exposed to vacuum, oil or chemicals application environment, polyimide heaters are ideal. Compared with silicone heating film, PET film or ceramic electric heating film, polyimide is more compact.

---Specification

|

Voltage range

|

0-380V

|

|

Power density range

|

0.03w/cm2-1.5w/cm2

|

|

Heater size

|

10mm-500mm(larger size also can be produced)

|

|

Insulation material

|

Polyimide film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm-0.3mm

|

|

Use environment

|

-190℃-190℃(Can't be heated in liquid)

|

|

Surface temperature

|

0-180℃(Can work for a long time within 150 degrees)

|

|

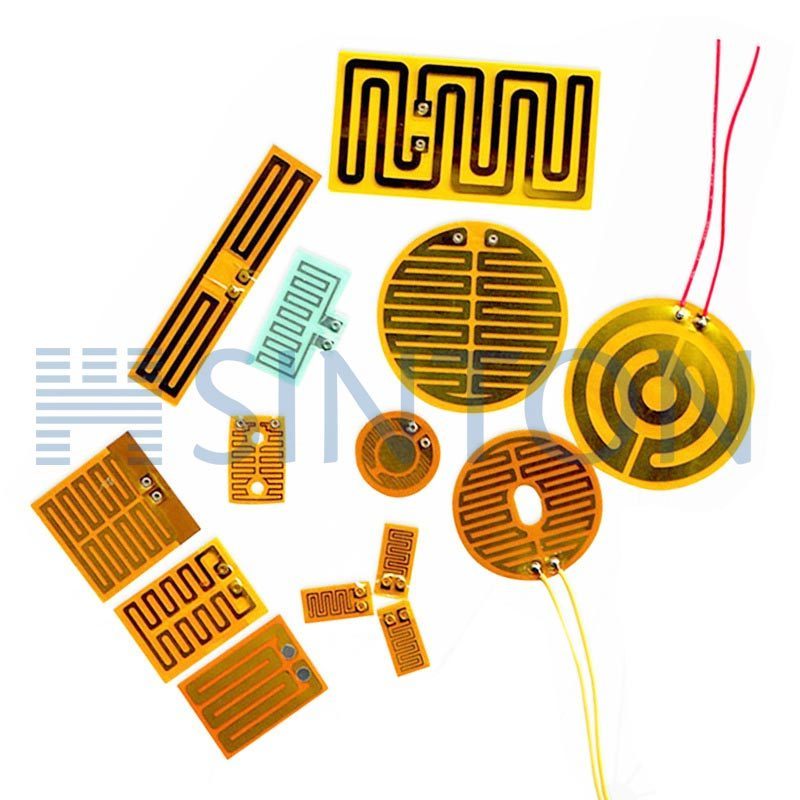

Products Shape

|

Any size within the plane (within the scope of production design)

|

|

Temperature control method

|

Adjustable temperature digital display temperature control, thermal protector, thermistor, K-type thermal resistance, etc.

|

Applications

1.Medical equipment such as blood analyzers and test tube heaters

2.Computer peripherals such as laser printers

3.Curing of plastic laminates

4.Photo processing equipment

5.Semiconductor processing equipment

6.Thermal transfer equipment

7.Heat various vessels and objects.

2.Computer peripherals such as laser printers

3.Curing of plastic laminates

4.Photo processing equipment

5.Semiconductor processing equipment

6.Thermal transfer equipment

7.Heat various vessels and objects.

Polyimide film electric heating film has been successfully applied to Fengyun series artificial satellites, Long March series

launch vehicles, Dongfeng, Hongqi and other series of missiles, as well as aircraft, ships, tanks, artillery gyroscopes,

accelerometers, fire control radar isothermal Control and heating system.

launch vehicles, Dongfeng, Hongqi and other series of missiles, as well as aircraft, ships, tanks, artillery gyroscopes,

accelerometers, fire control radar isothermal Control and heating system.

Product Features

①Heater thin and light so you can just position on the need for heating without heating part being avoided.

②Etched foil heating technology provides fast and efficient heat transfer and uniform heating surface, the temperature difference is minimal.

③Customization options (for example: SMT components, flex cable and connectors) can provide the perfect complete solution that can significantly reduce assembly time and increase productivity.

④Custom configured to provide balanced heating output performance to improve process yield and productivity, in accordance with requirements of additional temperature control device and temperature sensing devices.

⑤There FEP adhesive can be 200 ° C (392 ° F)

⑥Suitable for vacuum environments (NASA-RP-1061)

⑦ Resistant to most chemicals: acids and alkaline solvents erosion

⑧ If you are using polyimide insulated wires (custom option) can resist 106 rads of radiation, PSA adhesive stickers can be installed or epoxy adhesive, silicone adhesive installation.

⑨Providing a variety of complex shapes design, and different power designs. Membrane in the same piece electrically heated heating circuit can be designed and holding circuit

⑩Providing a liquid immersion design (non-standard)

Packing & Delivery

Our Company

SINTON GROUP was founded in 2001,formerly known as the trade of electric heating and instrumentation, the group's total assets are RMB120 million, with 360 employees. In 2010, we had our own factory building and 5A office production environment, From trade management to self-built factory, office building production and sales of explosion-proof heater ,air duct heater,pipeline heater, drying oven, gas mould temperature machine, electromagnetic thermal oil furnace, thermal oil furnace and all kinds of heating elements.From embarrassingly short of money to group management model, at present, we integrated research, development, production and sales the products are exported to 12 countries in the world,Mainly Europe and America with strong product independent research and development capabilities and technological innovation. The work has obtained the explosion proof authentication,many patents authentication, the quality system authentication.

FAQ

1. Why the price is so low?

You are ordering directly from the factory.

2.Where is your factory located? How can I visit there?

Our factory is located in Yancheng City, Jiangsu Province, China.

It almost takes 4 hours from Shanghai to Yancheng by bus. Welcome to visit us.

3.What types of payment do you have available?

We accept T/T and L/C as sample order, the western Union ,Money gram and Ali express is available.

4.How can I get some samples?

We are honored to offer you samples.

5.How does your factory do regarding quality control?

"Quality is our culture."We always attach great importance to quality controlling from the beginning to the ending

Welcome to contact us for more details...

Related products

Contact us

Hot Searches