NaN / 0

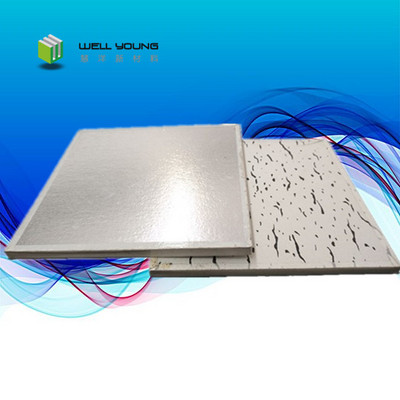

595 x 595mm PVC Laminated Gypsum Ceiling Tiles with Aluminum Foil Back

Get Latest Price

US$ 0.8

≥2000 Square meters

Quick Details

Warranty:

NONE

After-sale Service:

Online technical support

Project Solution Capability:

NONE

Place of Origin:

Shandong, China

Product Details

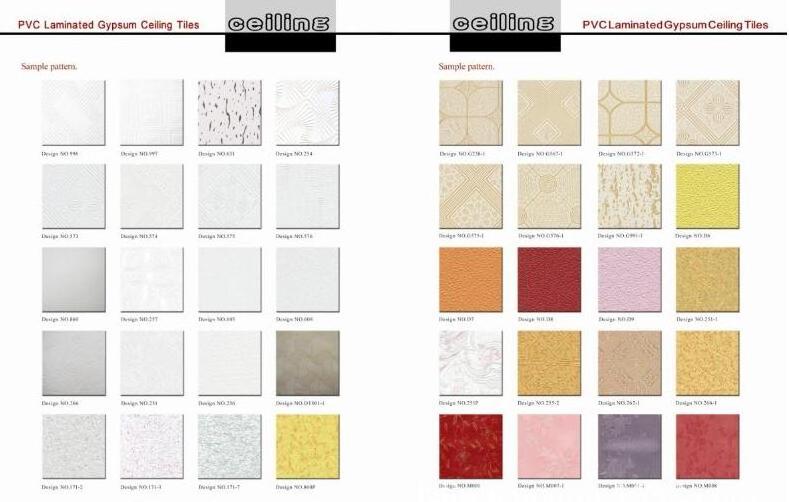

PVC Laminated Gypsum Ceiling Tiles

PVC Gypsum Board coated Aluminum Foil for Ceiling

The PVC aluminum foil veneer plasterboard is a kind of ceiling hanging top material .PVC veneer plasterboard with high grade aluminum foil on the back, also called PVC plasterboard, gypsum plaster board, three anti-cleanness plasterboard, using high quality plasterboard as raw material, front coating PVCs, top grade aluminum foil affixed on the back, PVC veneer plasterboard also called PVC plasterboard. Plaster ceilings, etc.

Characteristics:

1 dampness, fire resistance: This product uses PVC, aluminum foil veneer on the back side, uses waterproof tape to seal the edge around, achieves the waterproof goal truly, may maintain the performance in the kitchen, the dining room, the basement and so on damp space.

2 Flame retardant, fire resistance: This product is made of natural flame retardant material with combustion performance up to international GB8624A standard. Its good flame retardant property can fully meet the requirements of building engineering for fire prevention and fire protection.

3 High strength and no deformation: This product adopts high strength, high density raw material manufacture. The fracture load of the product is 499N.The fracture strength of the product is three times that of the international requirement of the ordinary ceiling, and it has the excellent characteristics of high strength and no deformation.

4 sound absorption This product has good sound insulation, sound absorption, sound insulation coefficient as high as 0.6-0.8.

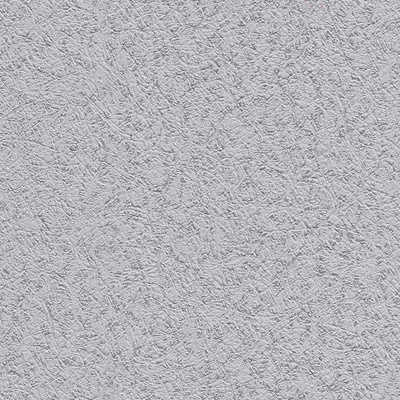

5 decorative: This product has various patterns, clear and elegant patterns, convenient construction design with unique and elegant decorative effect.

6. Green environment: The pvc films and adhesives used in the production of PVC plasterboard are all used for testing qualified natural raw materials by the national inspection department, and the materials have no micropores and gaps, so they will not pollute the indoor environment or produce harmful substances. It undefineds a real green material.

Technical Data:

|

Material: |

Gypsum board |

|

Surface treatment: |

PVC Transfer Coating and alumina foil on the back |

|

Thickness: |

8mm |

|

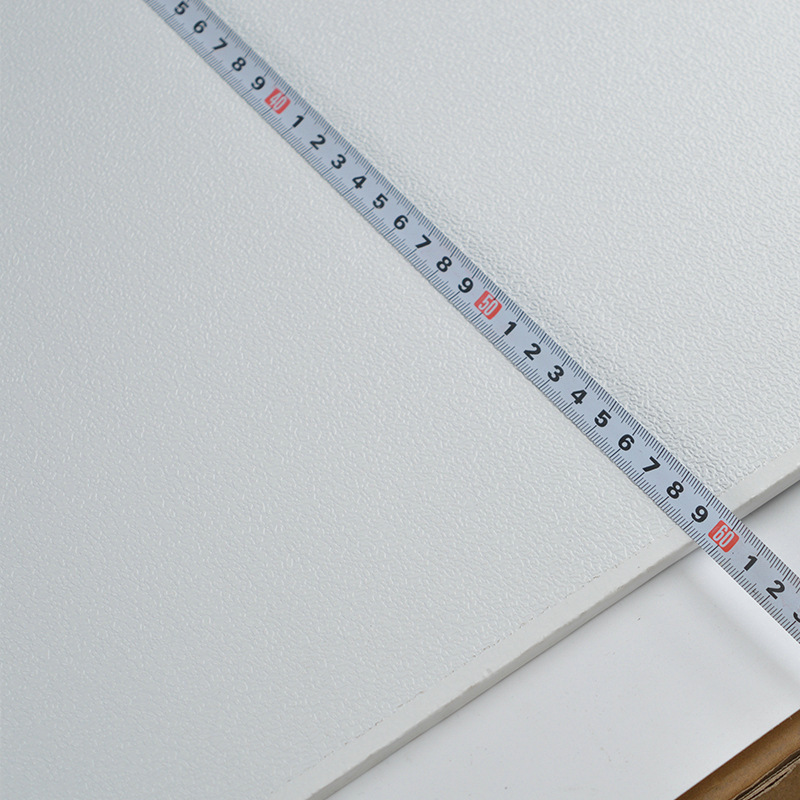

Nominal size: |

600mm×600mm 2’×2’ |

|

Actual size: |

595mm×595mm 603mm×603mm |

|

Tolerances: |

Length≤±2.0mm Width≤±2.0mm Thickness≤±0.5mm |

|

Weight/SQM: |

<7.0Kg/m2 |

|

Strength: |

Rupture index>150N |

|

Moisture rate: |

<1% |

|

Fireproof characteristic: |

Fire retardant material of B1 grade China GB8624-1997 |

|

Relative humidity requirements: |

≤90% |

Hot Searches