NaN / 0

Lock Air toggle clamp Pneumatic horizontal latch type toggle clamps latch 602 vertical type hold down toggle clamp

Get Latest Price

US$ 4.8

≥450 Pieces

US$ 3.5

≥1500 Pieces

US$ 2.6

≥3000 Pieces

Quick Details

Material:

Stainless steel, Metal

Place of Origin:

Zhejiang, China

Surface treatment:

Electroplate

Detecting instrument:

Tensile test, Micro-structure, Spectrometer, UT test, etc.

Product Details

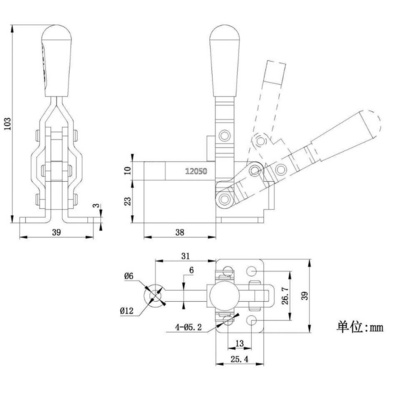

| Model | Description | ||

| Holding Capacity | 100KG |

12050 |

|

| Weight | 145g | ||

| Handle Moves | 60° | ||

| PLUNGER STROKE | 100mm | 12050SS | |

| Surface treatment | Electroplate | Detecting instrument | Tensile test, Micro-structure, Spectrometer, UT test, etc. |

| Structure | toggle clamp | Type | toggle clamp |

| Usage | Heavy Duty | dimension | according to your drawings |

| Standard or Nonstandard | Standard or Nonstandard | Material | Metal,Steel, Stainless Steel,Plastic |

| Model Number | as requirement | Name | quick release handle vertical toggle clamp |

kjf latch type carpenter kit toggle clamps with bit toggle clip clamp metal fasten pneumatic power lock double handle kakuta horizontal custom gh Pneumatic horizontal latch type toggle clamps air toggle clamp latch 602 vertical type hold down toggle clamp

Toggle Action:

The theoretical maximum holding or clamping force of a toggle action device is achieved when the three pivot points are in a straight line. To make allowance for external forces due to vibration and changing load conditions in industrial use, the proper amount of over travel of the center pivot point has been carefully calculated to yield maximum clamping pressure ,while achieving positive locking position.

Features :

1.Hand grips are covered with an oil and stain resistant red vinyl or red plastic for easy identification and to assure the safety and comfort of the operator.

2.All die-stamped steel parts are deburred, cleaned, and receive a zinc plated finish that resists corrosion and created a smooth, easy to clean surface.

3.Heavy duty rivets are used to maintain accuracy and to increase endurance. All heavy-duty clamps receive hardened ground pins and bushings.

4.Flanged washers are supplied with all U-Bar and open bar models. Weld-on bolt retainers are supplied with all solid bar models.

5.Toggle mechanism designed to allow maximum clearance for ease of loading and unloading work piece.

![[TANJA] 431 adjustable toggle latch / heavy duty horizontal latch type toggle clamp](https://cdn.bestsuppliers.com/seo_products_img/togglelatch/60360667671/1bd102b066c73a5fb9dc51d97848e1c7.jpg!/rotate/180/sq/400)