Product description

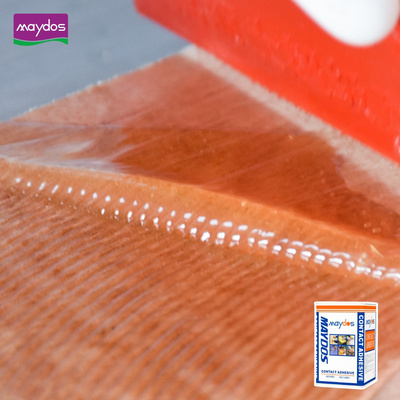

Maydos Spray Adhesive formulated with good-quality raw materials and

conforming to national compulsory standard-GB18583-2001 requirements of

restriction of harmful and hazardous substance, possesses such features as low VOC,

fresh smell, high solid content, good flexibility, easy application, strong adhesive

force, environment-friendly etc. And after hardening, it can be resistant to damp,

water, heat, acid, alkali and bumping, so it is widely used for bonding sponge, heat

insulated materials, fiber, wood and thin metal sheet.

Recommended use

It is suitable for bonding different materials such as sponge, heat-insulated materials,

fiber, wood and thin metal sheet.