NaN / 0

Scrap Paper Dry Pulping Line OCC Waste Paper Pulp Machine

Get Latest Price

US$ 128500

≥1 Sets

US$ 128000

≥5 Sets

Quick Details

Production Capacity:

10 T/H

Product Type:

Paper Recycling Machine

Processing Type:

Dry Pulp

Place of Origin:

Henan

Product Details

Products Description

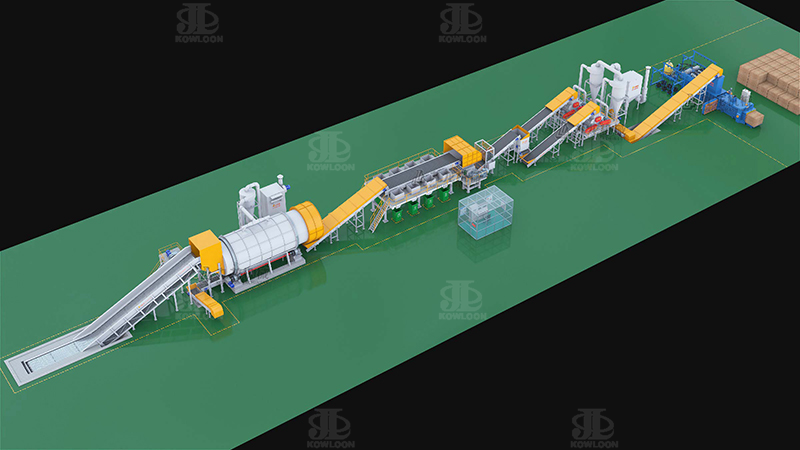

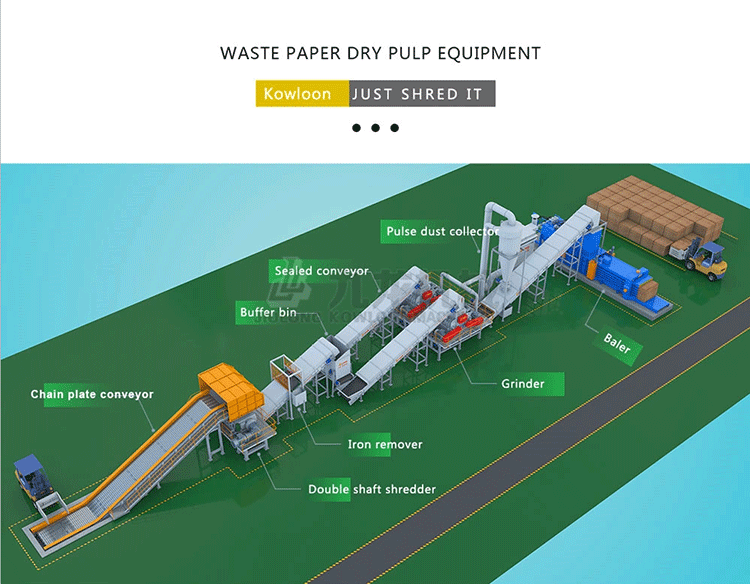

OCC Paper Dry Pulping Line

Waste paper recycling is a process of repeated paper making, mainly recycling paper fibers in waste paper, which can greatly save resources and reduce pollutant emissions. In foreign countries, waste paper has the reputation of urban forest resources. Whether it is waste newspapers, book paper, office paper, or kraft paper, cardboard boxes, corrugated paper, etc., they are all valuable fiber raw materials used in papermaking. Using waste paper to make paper has the advantages of low energy consumption, low processing cost, low unit raw material cost, and reduced environmental pollution. Therefore, paper and cardboard produced from recycled fibers are called green products.

Paper and cardboard are valuable materials as their fibers can be recycled. Our paper shredders allow for economical and environmentally friendly paper reutilization. The shredders crush and recycle paper and cardboard waste, delivering consistent and controllable discharge particle size. Custom paper recycling solutions are available according to your individual production requirements.

Technical Parameters

|

Model

|

JLSS1000

|

JLSS1200

|

JLSS1500

|

JLSS2000

|

|||

|

Motor

|

15kw+15kw

|

22kw+22kw

|

55kw+55kw

|

90kw+90kw

|

|||

|

Gearbox

|

2units,planetary type, gear transmission

|

|

|

|

|||

|

Shaft

|

solid shaft, made of 40Cr, hardened and tempered

|

|

|

|

|||

|

Shredder chamber (inner)

|

940x725mm

|

1120x1000mm

|

1450x1100mm

|

1920x1250mm

|

|||

|

Rotor rotary speed

|

8-18rpm

|

8-18rpm

|

8-18rpm

|

8-18rpm

|

|||

|

Blade

|

diameter 360mm

|

diameter 360mm

|

diameter 530mm

|

diameter 560mm

|

|||

|

Lubrication system

|

With automatic oil lubricator

|

|

|

|

|||

|

Dimension

|

3.2x1.3x2.3m

|

3.2x2x1.9m

|

4.9x2.8x2.8m

|

6x3.8x4.8m

|

|||

|

Weight

|

6000kg

|

12000kg

|

18000kg

|

29000kg

|

|||

|

Model

|

JLSD1500

|

JLSD1500D

|

|

Infeed port size

|

1468*450mm

|

1468*900mm

|

|

Hammer blade

|

66pcs, made of 65Mn

|

132pcs, made of 65Mn

|

|

Liner plate

|

M13Cr2, 42pcs

|

M13Cr2, 84pcs

|

|

Output material size

|

3-30mm (screen customizable)

|

3-30mm (screen customizable)

|

|

Main motor

|

75kw+75kw

|

75kw+75kw+75kw+75kw

|

|

Discharging conveyor motor

|

11kw

|

11+11kw

|

|

Feeding conveyor motor

|

4kw

|

4kw

|

|

Hydraulic motor

|

2.2kw

|

2.2kw

|

|

Output screw conveyor

|

Dia.273mm x 1, motor 7.5kwx1

|

Dia.273mm x 1, motor 7.5kwx1

|

|

Dust collector

|

48-bag pulse dust collector,4kw

|

96-bag dust collector,11kw

|

|

Cyclone

|

With air-lock valve, fan 7.5kw

|

With air-lock valve, 7.5kw x2

|

|

Dimension

|

3150*3250*3350mm

|

6150*3250*3350mm

|

|

Weight

|

5500kg

|

8500kg

|

Details Show

Heavy Duty OCC Paper Dry Pulping Line

Waste Paper Processing Line Dry Pulping System

Our solutions come in a modular design so you can customize them to match your production process. At Kowloon we focus on solutions that pay off, whether it's supplying the smallest spare part or serving as a long term partner. Complete Waste Paper dry pulping line includes the following equipments, from the storage of raw materials to the dry pulp production. Each section has professional equipment to work. Of course, according to the different needs, it may be the particularity of the raw materials or the limitations of the site. Our engineers will redesign the process, and the equipment used will be increased or decreased.

Raw Materials

There are five basic paper grade categories. While these terms may be most useful to paper mills looking to process certain kinds of paper, you may hear these terms once in a while, and it’s possible you’ll need to be able to distinguish between them.

1.Old Corrugated Containers – You might know this as “corrugated cardboard.” It’s most often found in boxes and product packaging.

2.Mixed Paper – This is a broad category of paper that includes things like mail, catalogs, phone books and magazines.

3.Old Newspapers – This one is pretty self-explanatory. Mills use newspapers, a lower grade paper, to make more newsprint, tissue and other products.

4.High Grade Deinked Paper – This quality paper consists of things like envelopes, copy paper and letterhead that has gone through the printing process and had the ink removed.

5.Pulp Substitutes – This paper is usually discarded scraps from mills, and you probably won’t have to worry about running into it, though it may find its way into products you buy.

1. Waste Paper Shredder

The main task of this section is to quickly shred any shape of waste paper boxes, old corrugated paper, hard paper, newspapers, used books, cartons, paper tubes, paper tubes, cardboard and other materials into small pieces.So a waste paper shredder is needed to complete the task.

2. Raw Material Crushing

The task at this stage is to further crush the raw material into small sawdust.Only paper waste that meet the size requirements can be directly fed into the hammer mill, or those that have passed the chipper and coarse crushing and require further fine powder.

Sawdust briquette baler

The punching briquetting press adopts machinery stamping force on the sawdust and forms them into solid cylindrical briquettes. It

can not only make the sawdust briquettes but also the sawdust pellets, what you need to do is replacing the forming mould.

can not only make the sawdust briquettes but also the sawdust pellets, what you need to do is replacing the forming mould.

Installed Projects

Hot Searches