NaN / 0

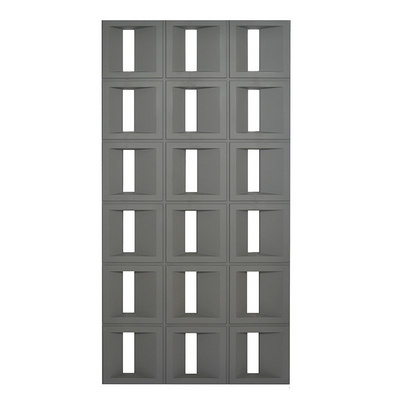

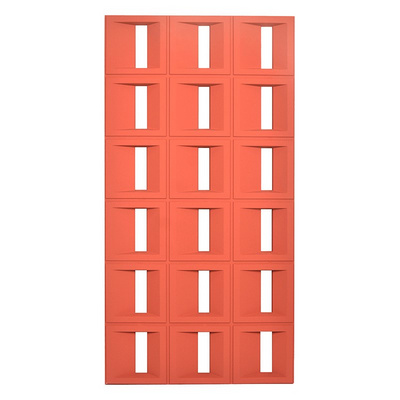

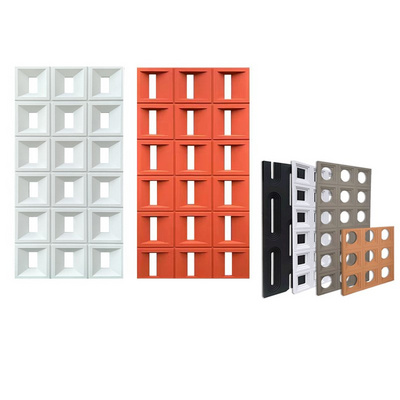

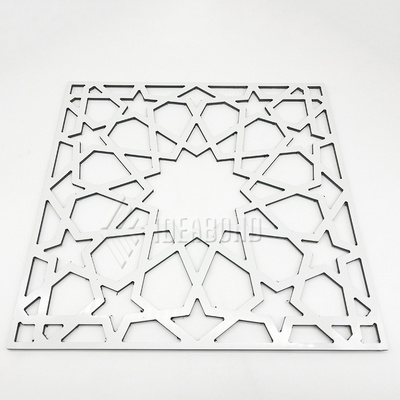

Decorative 3D Alucobond Aluminum Perforated Wall Cladding Panel

Get Latest Price

US$ 10

≥300 Square meters

US$ 9

≥1000 Square meters

US$ 8

≥5000 Square meters

Quick Details

Warranty:

More than 5 years

Size:

2440MM X 1220MM

Project Solution Capability:

Others

Application:

Hospital

Product Details

Product Description

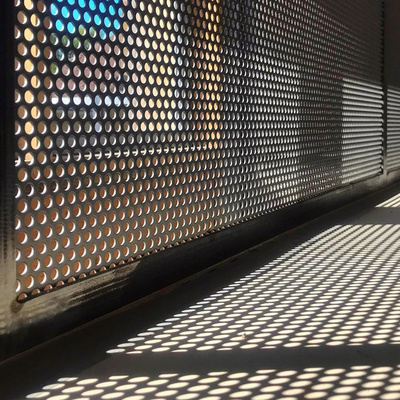

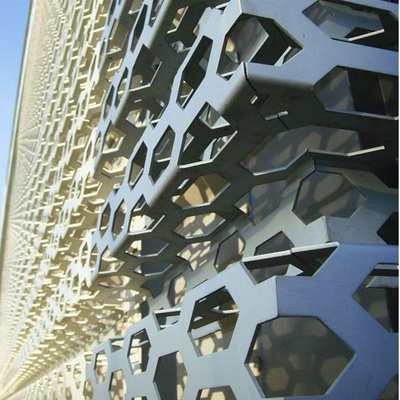

Decorative 3D Alucobond Aluminum Perforated Wall Cladding Panel

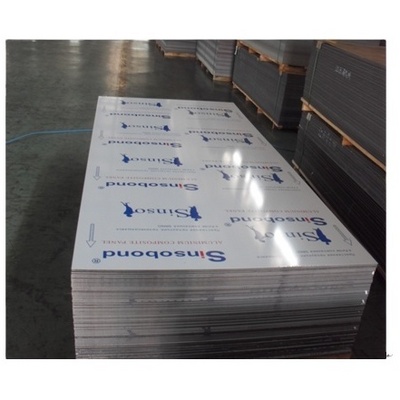

Product structure

All Aludream aluminum composite panels follow a general rule which is that two aluminum sheets are coupled or bonded upon a thick internal core made up of polyethylene. PVDF Aluminum composite panel follows the same principle of how aluminum composite panels are manufactured the only difference is that the final product involves a coating of PVDF (Fluorocarbon). Here are some of the salient features of PVDF aluminum composite panel.

Thickness:

The thickness depending on the brands and preference comes in various forms but due to

aluminum composite panel

having a coating of PVDF the panels would obviously thicker. In general PVDF aluminum composite panels are manufactured in 3, 4, 5 and 6mm which gives you an edge in the form of strength and durability.

PVDF Coating:

PVDF coating is an important element in the product and the manufacturing process simply because of the fact that it supplements the aluminum composite panel perfectly. PVDF is essentially a mixture of a number of components such as fluorocarbon resins which provides the fluorine enzyme, ester solvent, paint and alcohol. A mixture of these components makes a coating which gives more strength and resistance.

Cladding:

PVDF aluminum composite panels are extensively used for the purpose of cladding, as we have seen that their thickness along with the properties of PVDF are such that they are perfect material for cladding.

Features and Applications:

The features of PVDF aluminum composite panel are immense simply because of the fact that they make the surface of the panel even more flat. The coating gives the two aluminum sheets a surface whose essential feature is flatness and smoothness. Furthermore, the PVDF coating makes it even more weather resistant. Also features such as heat insulation, sound insulation and fire resistant add an entirely new dimension in Aluminum composite panels. The usage of PVDF aluminum composite panel is wide and has a variety of applications; it is frequently used as a raw material in industries, advertisement boards and exterior of buildings.

PVDF aluminum panel in essence is quite similar to the aluminum composite panel. The only difference lies in the coating which further refines things in a way that makes the PVDF panel quite an effective one.

Product Classification

Application Scope

1)Building exterior curtain walls

2)Decoration reformation storey-addition for old buildings

3)Decoration of interior walls,ceilings,bathrooms,kitchens and balconies

4)Shop’s door decoration

5)Advertisement boards,display platforms and signboards

6)Wallboards and ceilings for tunnel

7)Industrial material , vehicle and boat materials

Project Show

Colour Options

♦ Ordinary colors : more than 30 kinds of Solid colors and Metallic color reference.

♦ Customized colors : PANTON colors available;

♦ Mirror effect: Gold mirror, silver mirror effect available.

♦ Brushed effect

♦Wood | Marble designs:

wood | marble patterns can me print on surface with life valid of over 15 years.

More than 100 kinds of wood/marble designs are available.

Coating Difference

|

Aluminum Composite Panel Series |

|

|

PVDF Series |

The surface of PVDF aluminum composite panel is Polyvinylidene Fluoride (pvdf, 70%contents) with good weather resistance, impact resistance, UV resistance, sound and heat resistance, colorful, smooth and beautiful. Its life is about 20 years. It is mainly used for exterior decoration. |

|

PE Series |

PE ACP is a kind of new green composite material which compounded of two layers of aluminum sheets and nontoxic low-density polyethyene (LDPE) by macromolecule adhesive film of American DuPont Company through thermo compression, The coating of the aluminum sheet is polyester coating with UV resistance, Its life is about 15 years. It is mainly used for interior decoration and advertisement board. |

|

Mirror Finish Series |

The surface of the mirror finish ACP is the aluminum sheet that looks like a mirror. The back surface is aluminum sheet with anti-corrosion. The mirror finish ACP has the features of mirror effect, light weight, difficult to break, high strength, can be bent and easy to process. Thanks to those features, mirror finish ACP is increasingly used for interior decoration, especially in ceiling, Cabinet panel, household appliance, furniture. |

|

Nanometer ACP Series |

The coating of surface of nanometer ACP is PVDF coating, and then adds a self-clean layer on the surface of PVDF coating. The self-clean layer can prevent the pollutant such as ash layer and decompose the pollutant in the air to reach self-clean effect. Its features of stain resistance, self-clean, acid resistance, weather resistance of nano is superior to the traditional PVDF ACP. |

|

Fire-resistant Series |

Fire-resistance ACP is a kind of green fire-resistant composite material which is compounded of two layers of aluminum sheet and special low-density polythylene (LDPE) with fire-resistance. The coating of its surface is PE or PVDF coating. The core material is compounded by fire-resistant MGOH, NAOH and PE Polyster, so it has the feature of good fire-resistance which can reach B1 class. |

|

Drawing Finish Series |

Drawing finish ACP is compounded of drawing aluminum sheet, the anti-corrosion aluminum sheet, and nontoxic low-density polyethylene (LDPE). Thanks to the drawing treatment, its appearance is very beautiful. It is widely used for interior decoration, especially in ceiling, Cabinet panel, household appliance, furniture. |

Explore More Products

Hot Searches