NaN / 0

Waste Paper Pulper System Pulp Machine for Cardboard Paper Recycling Production Line

Get Latest Price

US$ 30000

≥1 Sets

Quick Details

Type:

Recycled paper machine

Production Capacity:

300-370t/d

Max. workable width:

Custom design

Place of Origin:

Henan, China

Product Details

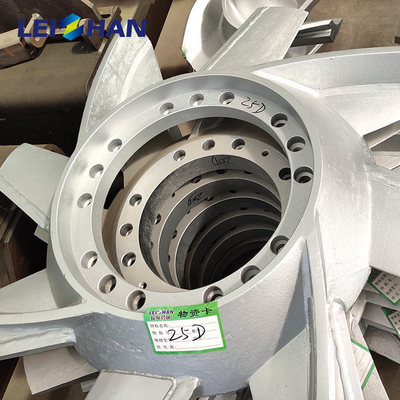

Waste Paper Pulper System Pulp Machine for Cardboard Paper Recycling Production Line

Description:

1. This pulper is improved for a higher work efficiency.

2. It can be used for pulping waste paper & wet strengh paper.

3. D type hydra pulper is mainly used to crushing pulp board, waste paper, deinking, and pulp purification.

4. Through dissociating, it can maximum make the paper’s fiber dissociating into fiber bundles or single fibers, while at the same time, it can maximize maintain impurity’s shape and strength.

Main specification

|

Type |

ZDSD 23 |

ZDSD 24 |

ZDSD 25 |

ZDSD 26 |

ZDSD 27 |

ZDSD 28 |

ZDSD 29 |

ZDSD 30 |

ZDSD 31 |

ZDSD 32 |

ZDSD 33 |

ZDSD 34 |

ZDSD 35 |

ZDSD 36 |

ZDSD 37 |

|

Normal Volume(m3) |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

60 |

70 |

90 |

120 |

140 |

|

Concentration (%) |

3-5 |

||||||||||||||

|

Product capacity(t/d) |

30-50 |

40-90 |

80-120 |

140-180 |

180-230 |

230-280 |

270-320 |

300-370 |

350-400 |

400-450 |

460-550 |

550-650 |

650-800 |

800-1000 |

1000-1200 |

|

Motor power(KW) |

75 |

110 |

160 |

185 |

220 |

280 |

315 |

355 |

400 |

450 |

560 |

630 |

900 |

1100 |

1250 |

Main feature

1. Pulper rotor off -center position, so that the waste paper could touch the rotor more quick, higher frequency.

2. The tank is made by welded steel,outside of mouth is ultra high strength steel,which used to strengthen tank, in the bottom of cone have deflector, which can make the paper pulp reflux circulating. In the bottom of tank is impurity discharge outlet.

3. Pulper rotor and pulp tray is higher than pulper groove bottom plane, which can reduce the pulper rotor and impurities contact, so that prolong life-span, preventing the twisted rope winding on the rotor.

4. Machine make egg tray has s cleaning function, easy to start the device.

5. Transmission design of the three sets of bearings, enhance equipment life, reduce maintenance costs.

6. Supporting the European standard pulley, shorten the maintenance time, improve work efficiency and reduce operating costs.

7. 25m ³ above the pulper has a drive support.

Detailed images

Waste paper recycling machine can promptly crushing waste paper, with large capacity, low power consumption, and saving vapour medication. And it is easy to maintain, with long service life, low noise, and the vibration is not strong, in stable operation, also it can save energy.

Working site show

Our Customers and Exhibition

Why Choose us?

Compared with others, we are the manufacturer, so we can make delivery in time and supply products with high quality and reasonable price, which are our outstanding advantages.

Our Service

Acceptance standard

Unless stipulated in the technical documents accordingly, technology acceptance standards of designed main parts are in accordance with relevant state departments issued current relevant standards.

providing main parts technology acceptance standard of technical design.

Technical service

During paper pulp machine installation, we cooperate with buyer for technological improvement to reach desired results.

We explains paper pulp machine performance, structure and operation to buyer related people for free.

Quality guaranteed

We make sure paper pulp machine achieve promised performance with correct installation, commissioning, normal operation and maintenance.

In warranty period, for quality problem, we repair and replace defective parts for free (except quick-wear part).

Hot Searches