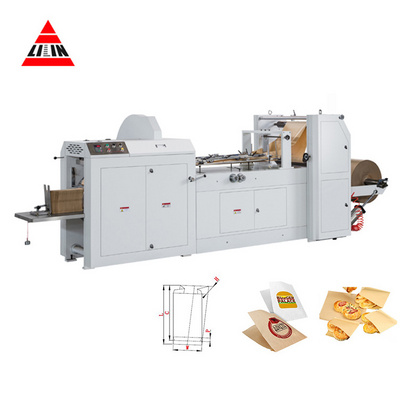

CY-290 type adjustable roll to square bottom paper bag making machine,has the advantages of high speed,high production efficiency and wide adjustment range. It is designed to manufacture square bottom paper bags from paper roll in blank or printed,and can complete side gluing, tube forming, cutting, bottom impressing, bottom gluing, bottom forming and final product output within one time. Controlled by PLC system,equipped with touch screen and servo motor for bag length control,this machine can produce a variety of specifications paper bags. It is an ideal equipment for making paper bag for foodstuff bag or shopping bag.

![[JT-HY270]CE Paper Bag Making Min Machine German Paper Bag Making Machine Manual Paper Bag Making Machine Price](https://cdn.bestsuppliers.com/seo_products_img/jeta/17c1ba615af43136bdaced2ec254d76c.jpg!/rotate/180/sq/400)

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/22c65a5d5893304db66b95efbe1aaf82.jpg!/rotate/180/sq/400)