NaN / 0

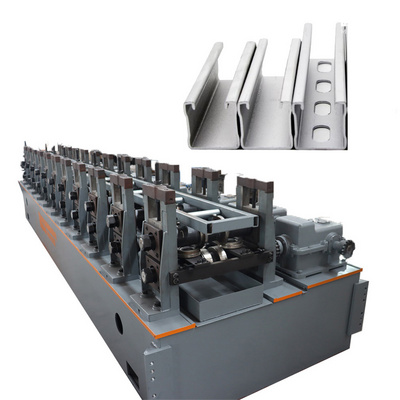

Solar Strut Channel Rolling Machine Solar Panel Support Uni strut C Channel Roll Forming Machine

Get Latest Price

US$ 23000

≥1 Sets

US$ 20000

≥3 Sets

Quick Details

Type:

Tile Forming Machine

Tile Type:

Steel

Production Capacity:

8-15meters/min

Rolling thinckness:

1-2.5 mm

Product Details

Product Description

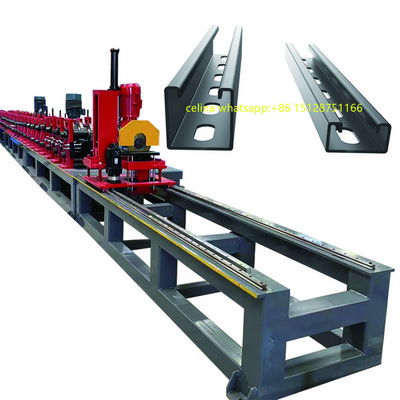

Solar Strut Channel Rolling Machine Solar Panel Support Uni strut C Channel Roll Forming Machine

Solar Strut channel has been using for many years while installing solar power. The biggest advantage of solar strut channel is that it helps in the construction and easily connects the length together and other items, by using different strut fasteners.

Strut channel can get jointed easily and quickly with minimal tools and labor. So in returns reduces the overall costs of the application. A strut channel installation can be easily modified or added to anywhere if needed.

Machine Paramenters

Profile drawing of

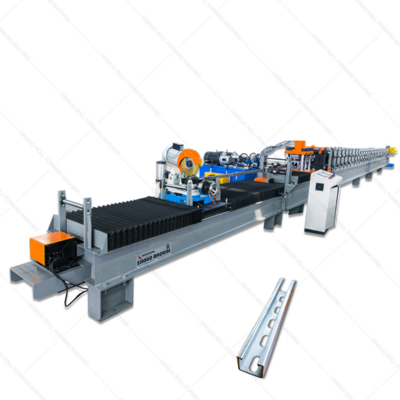

Solar Panel Strut Channel Machinery Unistrut C Channel photovoltaic support roll forming machine

1. Material thickness range:1.5-2.5mm,feeding width: 90-230mm

2. Main motor power: 22 k w

3. Forming speed:8 m/min

4. Shearing method: Hydraulic shearing.

5. Hydraulic station power:11 KW

6. Quantity of rollers:24 rollers

7. Shaft Material and diameter: 80 mm, material is 45# forge steel

8.Material Of machine body: 25mm 45# steel

9.Tolerance: +-1.5mm

10. Transmission method: By double chains

11.Material of forming rollers: GCR15 steel, coated with chromed treatment

12.Material of cutter blade: Cr 12 mould steel with quenched treatment 58-62℃

13.Voltage: 380V/ 3phase/ 50 Hz (as request)

2. Main motor power: 22 k w

3. Forming speed:8 m/min

4. Shearing method: Hydraulic shearing.

5. Hydraulic station power:11 KW

6. Quantity of rollers:24 rollers

7. Shaft Material and diameter: 80 mm, material is 45# forge steel

8.Material Of machine body: 25mm 45# steel

9.Tolerance: +-1.5mm

10. Transmission method: By double chains

11.Material of forming rollers: GCR15 steel, coated with chromed treatment

12.Material of cutter blade: Cr 12 mould steel with quenched treatment 58-62℃

13.Voltage: 380V/ 3phase/ 50 Hz (as request)

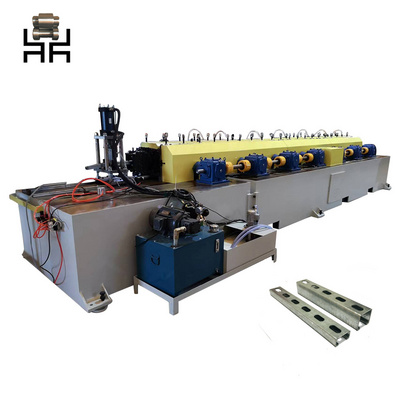

Details Images

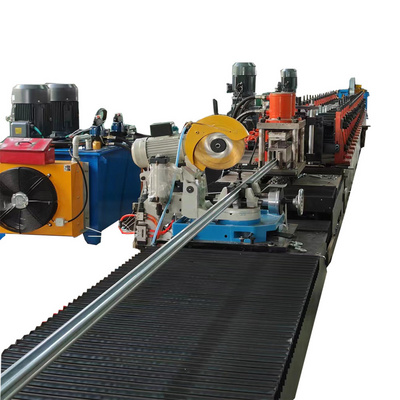

Hydraulic decoiler

Main Forming Machine (Gearbox drive)

Cutting system

Servo Motor No-Stop Hydraulic Cutting

Burr-free flying saw cutting

Auto Double Line Punching Machine

Packing & Shipping

1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded in one 40’ container.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.

2). The subjects can be loaded in one 40’ container.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.

Hot Searches