NaN / 0

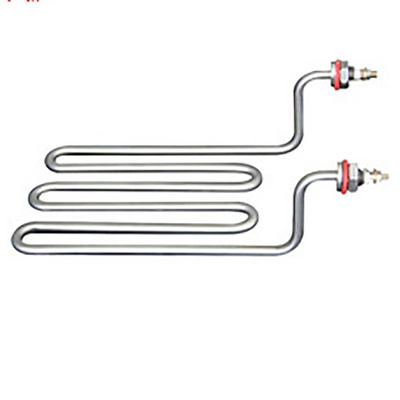

Faster cooking heating Tubular heater coil heating tube electric heat element for oven

Get Latest Price

US$ 8

≥1 Pieces

US$ 6

≥50 Pieces

US$ 3.5

≥100 Pieces

Quick Details

Type:

coil heater

Power Source:

Electric

Voltage:

360V

Place of Origin:

Jiangsu, China

Product Details

Product Description

Air immersion tubular heater is custom designed in a various shapes to as client's requirements for direct immersion in liquids such as water, oils solvents and process solutions, molten material as well as air and gases. Tubular heaters are produced using stainless, stainless steel or Copper sheath materials and also there is huge variety of selection of terminal styles available. Insulation of Magnesium offers greater heat transfer. Tubular heaters can be used in any application. Straight tubular can be inserted in machined groves for conductive heat transfer and formed Tubular provides consistent heat in any type of special application. It's applications areas are : Plastic processing manufacturers; Engineering Industry; Packaging machinery; Shoe making manufacturers; Foundry Equipment; Radiant Surface heating ; Hot Runner Molding Systems etc...

Pipe Specifications

304 stainless steel: It is suitable for most working environments.

304 seamless stainless steel: It is suitable for high temperature environments above 300 degrees.

316L stainless steel: It is suitable for acid and alkali corrosion working environment

2520 stainless steel: It is suitable for high temperature environments above 600 degree.

Specifications determination

①Voltage: 220V/380V.

② Thread specification.

③ Terminal (Mounting holes)center distance: About 4-6 cm It can be adjustable.

④Tube length: The length can be slightly different, as long as it can be loaded into the device.

Product Paraments

Product Materials

Product Show

Applications

Packing & Delivery

Certifications

Our Company

Hot Searches