NaN / 0

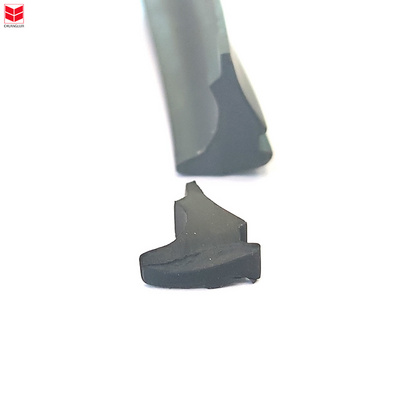

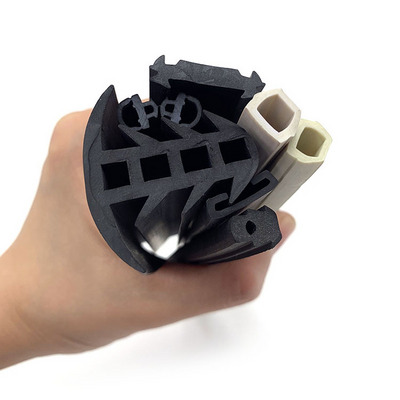

Rubber PVC window sealing strip door waterproof strip custom made rubber window seal

Get Latest Price

US$ 1.5

≥300 Meters

US$ 1

≥500 Meters

US$ 0.75

≥1000 Meters

Quick Details

Processing Service:

Cutting, Moulding

Place of Origin:

Jiangsu, China

Brand Name:

CSSSLD

Model Number:

Soft rubber sealing strip

Product Details

Industries that use plastic tubes: Medical Industry: Plastic tubes are widely used in the medical industry for various applications, such as IV tubing, catheters, and surgical instruments. Packaging Industry: Plastic tubes are used in the packaging industry for various applications, such as packaging for cosmetics, toothpaste, and pharmaceuticals. Food and Beverage Industry: Plastic tubes are used in the food and beverage industry for various applications, such as packaging for condiments, sauces, and beverages. Chemical Industry: Plastic tubes are used in the chemical industry for various applications, such as transportation of chemicals, and for the production of chemical reaction vessels. Construction Industry: Plastic tubes are used in the construction industry for various applications, such as the transportation of liquids, gases, and for the protection of wiring and cabling. Automotive Industry: Plastic tubes are used in the automotive industry for various applications, such as for fuel lines and coolant lines. Agriculture Industry: Plastic tubes are used in the agriculture industry for various applications, such as for irrigation and as conduits for wiring.

Our Advantages

CSSSLD provide on-stop custom plastic product service Including professional Design, Develop, skilled manufacturing, active service and effective feedback.

SERVICE:

PLANING & DESIGN:

Concept discussion. Own design team can help you from concept to product

design.Do feasibility analysis before develop. Design various kinds of molds to make product true.

design.Do feasibility analysis before develop. Design various kinds of molds to make product true.

DEVELOP:

Suggestion and confirm the Raw material.SGS,ROSH,MSDS or other specifications approved per customer requested. 3D or CNC prototypes to check first before design confirmed(optional). Extrusion, injection or rubber mould and tools developing by CSSSLD.

MANUFACTURING:

Samples approved, mass production according to it. Sufficient raw material stocks sustain smoothly production and control the steady cost. Effective inspection during and after production control the defective rate below 2%. Custom good packing for all kinds of custom goods.

SERVICE:

Cost-effective for good delivery service (optional). Continuous to following up, active and effective feedback solutions

service.

service.

FAQ

What is plastic extrusion?

Plastic extrusion is the process of melting plastic pellets or powder and forcing the molten material through a die to form a continuous shape. The shape can be customized to meet specific requirements and can be used for a variety of applications.

What types of plastic can be extruded?

A variety of plastics can be extruded, including polyethylene, polypropylene, PVC, ABS, and polystyrene, among others.

What products can be made with plastic extrusion?

Plastic extrusion can be used to create a wide range of products, including pipes, tubes, profiles, among others.

What are the benefits of plastic extrusion?

Plastic extrusion offers several benefits, including low tooling costs, high production rates, and the ability to produce complex shapes and sizes. It also provides consistent quality and high precision, making it an ideal manufacturing method for a variety of applications.

How does a plastic extrusion factory work?

A plastic extrusion factory typically begins by melting plastic pellets or powder and feeding the molten material into an extruder. The extruder then forces the molten material through a die, which shapes it into the desired product. The product is then cooled and cut to the desired length.

What factors should be considered when choosing a plastic extrusion factory?

When choosing a plastic extrusion factory, factors such as quality, cost, production capacity, lead time, and customer service should be considered. It's important to choose a factory that has experience and expertise in the type of plastic extrusion required for your specific product.

What is the lead time for plastic extrusion products?

The lead time for plastic extrusion products can vary depending on the complexity of the product, the size of the order, and the availability of materials. It's important to discuss lead time with the plastic extrusion factory prior to placing an order to ensure that it meets your production timeline.

What quality control measures are in place at plastic extrusion factories?

Quality control measures at plastic extrusion factories may include regular testing of raw materials, monitoring of production processes, inspection of finished products, and adherence to industry standards and regulations.

Can plastic extrusion products be customized?

Yes, plastic extrusion products can be customized to meet specific requirements, including size, shape, color, and material properties.

What is the cost of plastic extrusion products?

The cost of plastic extrusion products can vary depending on several factors, including the type and amount of material used, the complexity of the product, and the production volume. It's important to discuss pricing with the plastic extrusion factory prior to placing an order to ensure that it fits within your budget.

Hot Searches