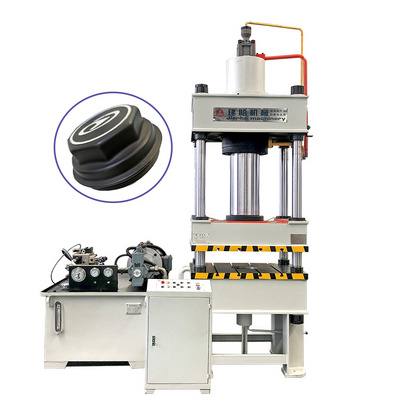

The overall box body mortise and tenon welding, steel plate thickness of more than 16MM, groove, each weld is welded more than 3 times

The column is made of 45# steel, the surface is plated with hard chrome, the four-column guide sleeve is made of wear-resistant

material, and the thin oil centralized lubrication system is used to reduce friction resistance.