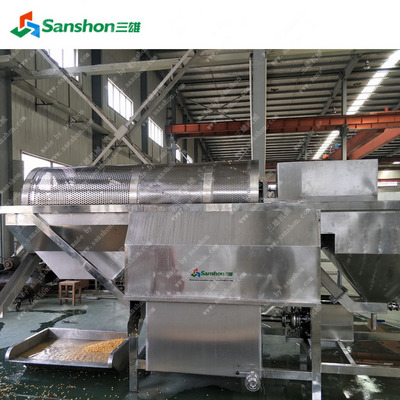

Name: debris removing tank

After feeding into washer inlet, sweet corn kernel goes into debris removing tank evenly under the function of water flow. In the debris removing tank, the first groove is for heavy debris; through adjusting the water flow, make the debris heavier than sweet corn kernel sink into bottom.