NaN / 0

VGCF vapor grown carbon fiber high temperature purification Graphitization Furnace 3000 degree Keep warm for 2 hours

Get Latest Price

US$ 4900

≥1 Sets

Quick Details

Place of Origin:

Hunan, China

Brand Name:

CX-induction

Voltage:

380V

Dimension(L*W*H):

400*400*1000mm

Product Details

VGCF vapor grown carbon fiber high temperature purification Graphitization Furnace 3000 degree Keep warm for 2 hours

Product Description

The Extreme Temperature Graphitization furnaces use medium frequency induction heating method. A water cooled induction coil installed inside the furnace. At the center of the coil, there is a graphite crucible as the susceptor for the induction current, surrounded by carbon felt as the insulation material.

CX-GF series are front loading batch type induction heating furnaces with round or cubic hot zone shape. Cubic hot zones are specially designed for clients who are not satisfied with round hot zones due to some reasons such as dead space.

Maximum operating temperature of 3000°C can meet all demands in carbon material’s graphitization treatment.

Horizontal design of these series, features simple working principle compared to vertical series. The main advantages of horizontal design are easy loading/unloading, easy clean-up of furnace inside, simple operation and maintenance for workers, and easy replacement of consumable spare parts.

Main Application:

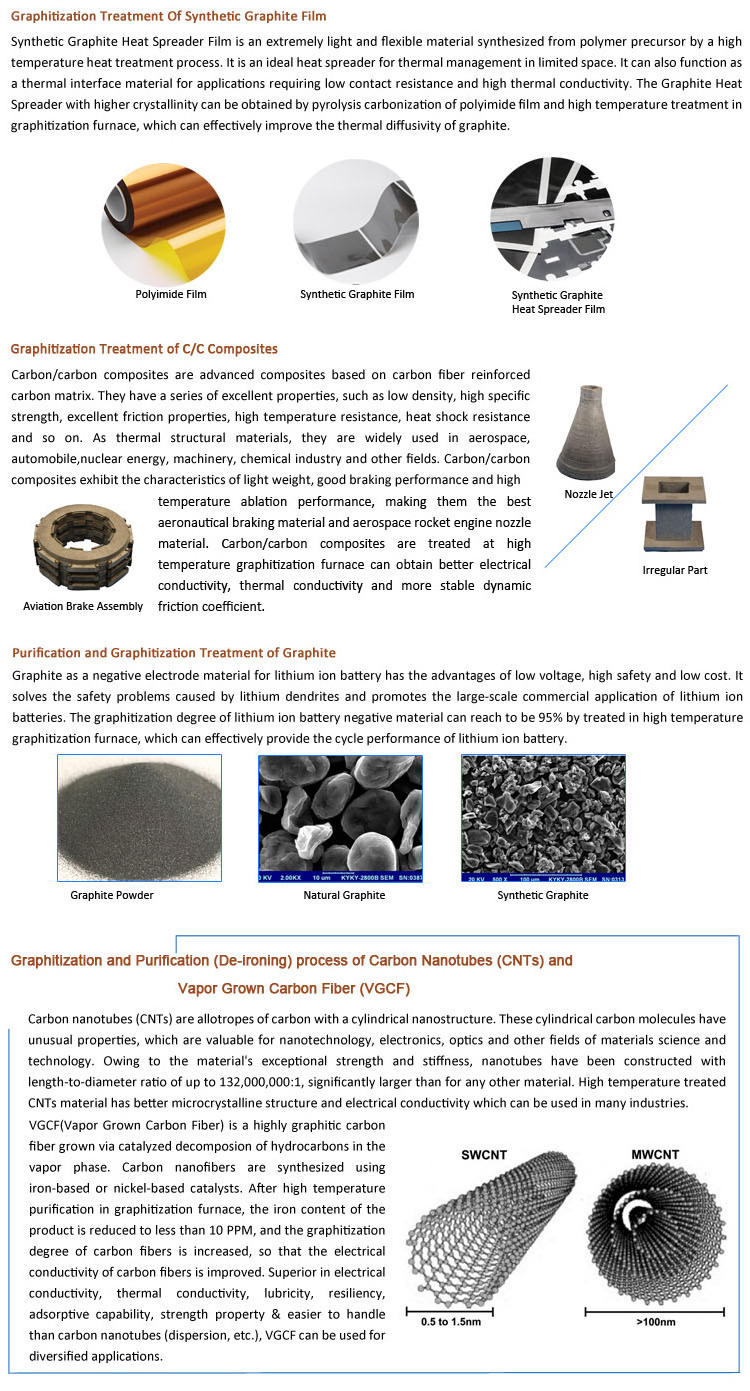

Graphitization treatment of Carbon materials and Heat Conductive materials, like synthetic graphite film (Polyimide Graphite film, abbreviated PI film), C/C Composites materials, Graphene, Lithium Battery Negative Electrode Materials, Carbon Fiber and Carbon fiber ropes, etc. Purification and Graphitization process of nature graphite and synthetic graphite. Purification and De-ironing process of Carbon Nanotube (CNT). Sintering of high temperature ceramics, other materials which can be sintered or heated in graphite hot zone (carbon included environment).

Technical Parameters

| Model | CX-GF40/100R |

| Max. Working Temperature | 3000℃ |

| Usable Space Dia.*L(mm) | 400*1000 |

| Power Supply (Custom) | 3P, 380V, 50HZ/60HZ |

| Heating Power | 200KW |

| Frequency | 2000HZ |

| Ultimate Vacuum (CEDRT*) | 1.2*10 -3 mbar |

| Optional High Vaccum (CEDRT*) | 5*10 -5 mbar |

| Working Atmosphere |

High vacuum (optional) / Vacuum / Inert gas (Ar or N 2 ) Vacuum and high vacuum atmosphere are only permitted up to 2200 ℃ |

| Temperature Uniformity | ±10℃ |

| Max. Heat-up Rate (CEDRT*) | 15℃/min (RT~1500℃),10 ℃/min (1500℃~2500℃),5 ℃/min (2500℃~3000℃) |

| Pressure Rise | 1.3*10 -2 mbar/hr |

| Temperature Measurement Range | 1000-3000℃ |

| Temperature Control Method | PID temperature control and manual temperature control |

| Cooling Water Pressure | 1.5~2.5 bar |

| Cooling Water Temperature | ≤28℃ |

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace

Related Products

Packaging & Shipping

We have more than ten years of exporting experience;

We have long term cooperation freight forwarding in exporting, customs declaration line.

We can choose the best and economy transport way for you.

Why Choose Us?

Hot Searches