NaN / 0

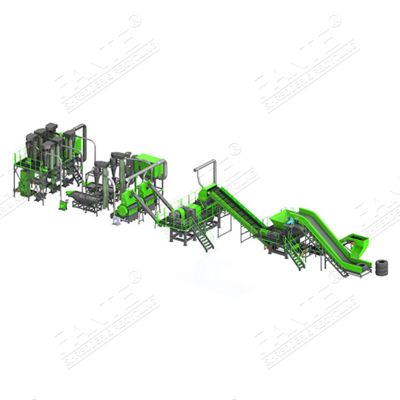

XKP Series Automatic Rubber Powder Recycling Line For Waste Tire Recycling Recycled tires rubber crusher machine

Get Latest Price

US$ 35000

≥1 Pieces

Quick Details

Place of Origin:

Henan, China

Brand Name:

like

Voltage:

as request

Dimension(L*W*H):

to be specified

Product Details

XKP Series Automatic Rubber Powder Recycling Line For Waste Tire Recycling

Product Description

1.We have specialized intire recycling machine for over 20 years, and exported to many contries.

2.There are fully-automaitc, semi-automatic, and PLC control fully automatic machine for customer.

3.From tire recycling line, you will get rubber block, rubber granule, rubber powder.

4.According to customer capacity requirement and finished products, we will customized the suitable technical scheme for them.

Flowchart of fully tire recycling machine:

Description of equipment of fully automatic machine line:

1. tire de-beader: to d raw out the steel wires fr om tire bead

2. tire cutter: to cut large dia tire into small pieces, then put into tire shredder. it is optional, based on the tire size.

3. tire shredder: to make rubber block from whole tire

4. rubber crusher: make rubber powder and granule in 5-40mesh.

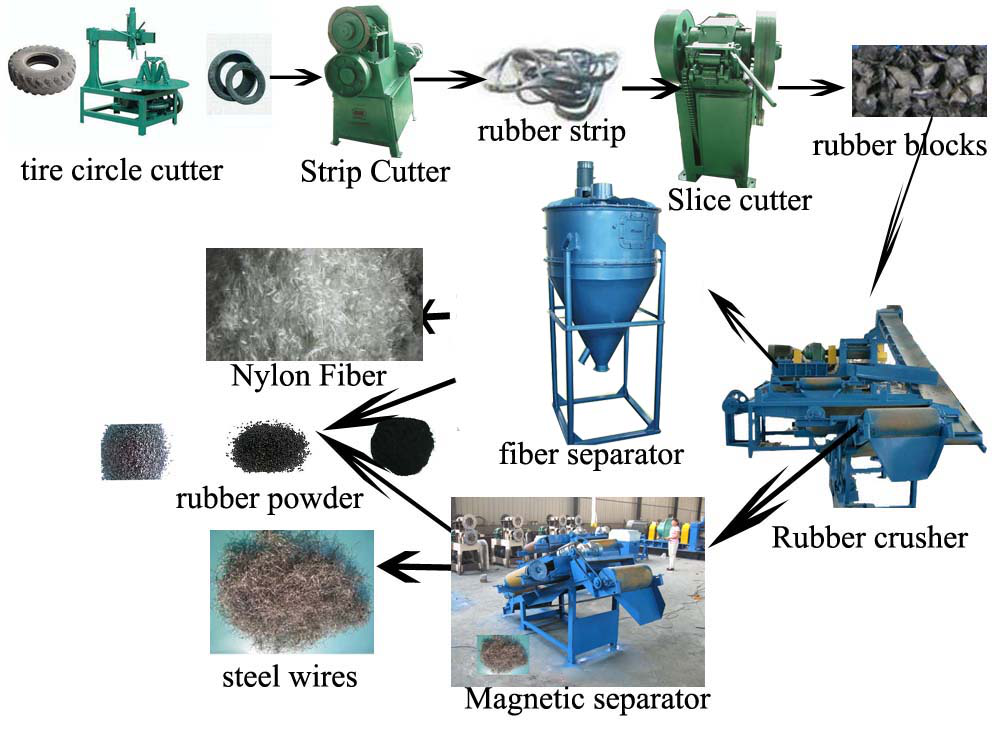

Flowchat of semi-automatic tire recycling machine

Description of equipment of fully automatic machine line:

1. TIre circle cutter: to cut the open the joint of tire bead and side

2. Rim separator: to separate the steel rims and the rubber on the mouth.

3. Tire strip cutter: to cut circle of the tire into 5-8cm strips

4. Tire slice cutter: to cut tire strip into rubber blocks

Host equipment rubber crusher:

Technical parameter of rubber crusher:

| Model | Drum diameter | Drum length | Front roll linear | Roll speed ratio | Max roller spacing | Motor |

| xkp350 | 300mm | 500mm | 26.2m/min | 1:2.5 | 8mm | 30kw |

| xkp400 | 400mm | 600mm | 34.5m/min | 1:2.5 | 8mm | 45kw |

| xkp450 | 450mm | 760mm | 38.0m/min | 1:2.5 | 8mm | 55kw |

| xkp560 | 560mm | 800mm | 38.6m/min | 1:2.5 | 8mm | 75kw |

| xkp560D | 560mm | 1000mm | 42.5m/min | 1:2.5 | 8mm | 132kw |

Packing of tire recycling machine:

Hot Searches