NaN / 0

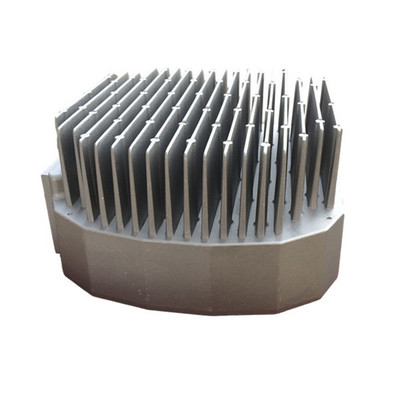

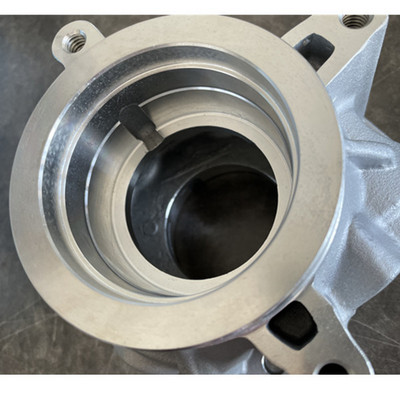

Aluminum alloy A356 t6 Gravity Casting Die Casting Parts

Get Latest Price

US$ 2

≥100 Pieces

US$ 1.9

≥1000 Pieces

US$ 1.8

≥2000 Pieces

Quick Details

Place of Origin:

Tianjin, China

Brand Name:

HYRH

Model Number:

Customized

Product name:

Aluminum alloy A356 t6 Gravity Casting Die Casting Parts

Product Details

Products Description

|

Company Name:

|

Tianjin HYRH Casting Co.,ltd.

|

|

|

|

|||

|

Business Type

|

Manufacturer

|

|

|

|

|||

|

Main Product

|

We provide castings or finished parts for various industries,the material is ADC12/A380/A356-T6 aluminum alloy die casting and so on.

Based on different national material standard,HYRH provide castings with aluminum alloy wide range of industries,e.g. Pump&Valve, Hydraulic, ConstructionMachinery, Truck, Mechanical And Electrical, Pipe Fittings……

|

|

|

|

|||

|

About HYRH

|

Since 1996, our company is focused on providing high quality aluminum die casting ,gravity casting ,sand casting ,precision casting blank parts, Machining parts and finishedparts. And providing castings or finished parts for a variety of industries, such as valve, gear box, engineering vehicles and engineering machinery, agricultural machinery, electric motors and generators, transportation facilities and other industries.

|

|

|

|

|||

|

Technology development& Extra service

|

1/In development of casting molding process, we use 3D model design and digital pouring simulation to improve casting process yield and deduct process defect risk, then Improve development efficiency.

2/In machining process development, we use 3D model design and fixing simulation and optimize cutting tools to improve development efficiency and make sure process reliability

3/We supply whole processes service from casting design to finish machined parts. The extra services include optimize casting structure to easy molding and reduce casting cost to help customers’ competitive ability improvement .

|

|

|

|

|||

|

Quality Control

|

Comprehensively use process control methods, running molding sand test and inspection, including green compression strength,moisture content, clay content etc. Casting process control, including spectrometer analysis, Metallographic examination, hardness

and mechanical properties test. For machined parts, we use CMM to confirm the key dimensions and IPQC method to control production quality. Random inspection to be applied for the finished products, all the processes are controlled to ensure the qualified products to deliver to customers. |

|

|

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity.

|

|

|

|

|||

|

Production Line:

|

High pressure die casting -low pressure die casting -gravity casting -precision casting ;sand casting ;lost foam casting ;

|

|

|

|

|||