NaN / 0

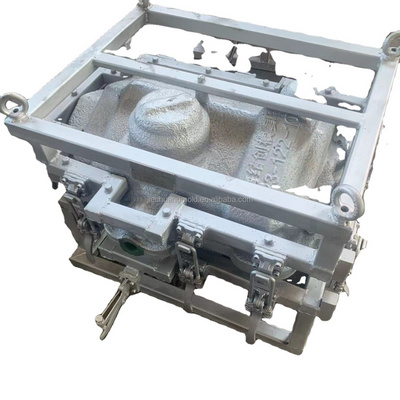

aluminium boat rotational molding mould 2024 aluminum alloy casting CNC machining rotationally

Get Latest Price

US$ 5000

≥1 Sets

Quick Details

Shaping Mode:

Die Casting

Place of Origin:

Shanghai, China

Brand Name:

Jiuchuang

Model Number:

Customized

Product Details

Product Description

|

Poduct Name

|

aluminium boat rotational molding mould

|

|

Material

|

aluminum A356, aluminum 6061t6( aluminum block)

|

|

Surface treatment

|

Polish, Sandblasting, Telfon coating

|

|

Wall thickness

|

8-10mm

|

|

Mould life

|

Over 5000 shots

|

|

Mould Process

|

Design, foam, casting, CNC process, Polish, Frame, Test, Packing

|

|

Platic Material

|

LLDPE, MDPE, HDPE, CROSS LINKED PE

|

|

Our service

|

help you design with our professional experience for rotational mold

|

1.

About Rotational Moulding:

Rotational moulding, known also as rotomolding or rotocasting, is a process for manufacturing hollow plastic products. For certain types of liquid vinyls, the term slush molding is also used. Rotational molding has particular advantages in terms of relatively low levels of residual stresses and inexpensive molds. Rotational molding also has few competitors for the production of large (> 2 m3) hollow objects in one piece. Rotational molding is best known for the manufacture of tanks but it can also be used to make complex medical products, toys, leisure craft, and highly aesthetic point-of-sale products.

The process begins with specially developed and uniquely applied resins. They can include plastisols, polyethylene, polycarbonate, acetate butyrate, polyamide, elastomers, polyurethane, polypropylene, ethylene vinyl acetate and fluorocarbons. Some of the most advanced work is being done with cross-linked polyethylene and even nylon.

The principle of rotational molding of plastics is simple. Basically the process consists of introducing a known amount of plastic in powder, granular, or viscous liquid form into a hollow, shell-like mold.The mold is rotated and/ or rocked about two principal axes at relatively low speeds as it is heated so that the plastic enclosed in the mold adheres to, and forms a monolithic layer against, the mold surface. The mold rotation continues during the cooling phase so that the plastic retains its desired shape as it solidifies. When the plastic is sufficiently rigid, the cooling and mold rotation is stopped to allow the removal of the plastic product from the mold. At this stage, the cyclic process may be repeated. The basic steps of (a) mold charging, (b) mold heating, (c) mold cooling, and (d) part ejection are shown in Figure below.

Products Show

Advantage

Design flexibility allowing complex geometry

· Cost saving - Projects of 50 to 30,000 are ideal

· Molds cost less then other molding methods

· Parts offer strength and durability

· Stress free parts

· Short lead times on production

· Consistent wall thickness

· Limited materials waste

· Small to very large hollow parts can be produced

· Part surfaces can have various textures

Our Company

Factory

Our Factory

Office building

Our office building

Workshop

Our workshop

Our Team

the most professional designer for rotational mold in China

MOULD PROCESS

Design

Foam

Die casting

CNC processing

Polish

Mould framing

Mould test

Qualified sample

Package

Our Service

1. Design & Engineering Services

Beginning a new project starts with a solid design concept. Our in-house Design & Engineering Department will help advise and manage your project all the way to a produced rototmolded part.

Whether your project is a rough idea or a 3D model, we believe in developing a partnership early on with the customer and strive to reduce lead times and so both parties benefit from rotational molding.

2. Rotational Molding Design Guides

·

Minimum wall separation 5x wall thickness (a)

· Minimum wall separation 3x wall thickness (b)

· Uniform wall thickness ± 20% (c)

· ±10% is considered precise tolerance (c)

· Wall thickness .090" to 1.00" (c)

·

Different wall thickness can be produced based on functional requirements

· Large flat areas need a crown or ribs (d)

· Corners need minimum radius of 3/16"(e)

·

Structural strength

· Reinforcing ribs - average proportions

· Height 4x wall thickness (f)

· Width 5x wall thickness (g)

·Kiss-off ribbing (h)

·

Part Finishing and Secondary Operations

Note: Design Guide information is based on Linear Low Density Polyethylene (LLDPE) other materials tolerance can vary.

3. Cast Tooling Pattern

When your design is finalized the pattern production begins. Most commonly patterns are CNC machined from the 3D model, but other options are available.

After the pattern is reviewed and signed-off on, the followers for determining the parting lines are constructed. Next, the pattern goes through the sand ramming process creating the cope and drag. Then our Tooling Department is ready to pour the tool.

4.Rotational Molding Plastic Parts

Rotational Molding, also called rotomolding or rotocast, is a thermoplastic process for producing hollow parts by placing powder or liquid resin into a hollow mold and then rotating that tool bi-axially in an oven until the resin melts and coats the inside of the mold cavity. Next the tool is cooled and the part is removed from the mold.

Four steps in manufacturing a rotational molded part

1. Fill the mold with a polymer material

2. Heat tool in oven to melt material

3. Cool tool to solidifies the part

4. Remove part from the tools

Our Company

Shanghai Jiechuang Mold Manufacturing Co.,Ltd.Combined professional experience in varied and demanding rotational molding applications, exceeding customer's expectations both nationally and internationally for over 10+ years.

We will provide you with a true one-stop shop for all of your product design, prototyping, tooling and full-scale manufacturing needs.

We offer significant differences compared to other molders including:

· Project Management

· Design and Engineering

· Research and Development

· Rapid Prototyping

· In-house Cast Aluminum Tooling

· Rotational Molding (Rotocasting)

·

Multi layer Part

· Molded-in Inserts

· Mold In Graphics

· In Mold Painting

· Secondary Operations

· Post Mold Finishing

· Light Assembly

· Mold On Graphics

· Post Mold Painting

· Product Testing

· Graphic Design and Layout

· Packaging and Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 35 days after confirming drawing and receive advanced payment.

Q: Do you provide samples once open mould?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% advanced payment, the balance before shippment.