NaN / 0

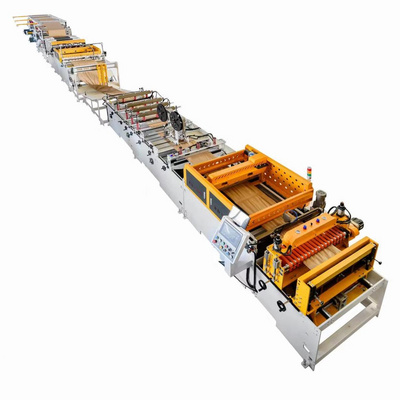

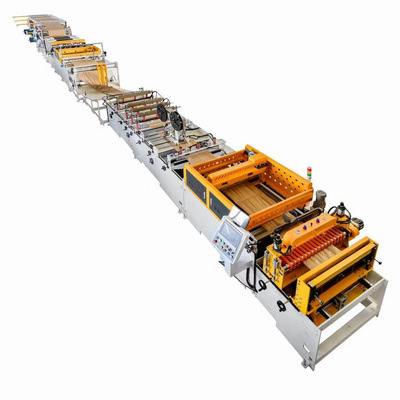

Honeycomb paper padded mailer envelope bag machine conversation production making machine

Get Latest Price

US$ 138800

≥1 Pieces

US$ 125800

≥3 Pieces

Quick Details

Machine Type:

Bag Forming Machine

Bag Type:

Patch Bag

Material:

Paper

Place of Origin:

China

Product Details

Specification

|

Material:

|

Kraft Paper ,Honeycomb Paper

|

|

|

|

||||

|

Unwinding Width:

|

≦1500 mm

|

Unwinding Diameter:

|

≦1200 mm

|

|

||||

|

Speed of Making Bag:

|

30-60 units /min

|

|

|

|

||||

|

Machine Speed:

|

70 /min

|

|

|

|

||||

|

Bag Width:

|

≦800 mm

|

Bag Length:

|

700 mm

|

|

||||

|

Unwinding Shaft:

|

3 inches Air Swelling Shaft

|

|

|

|

||||

|

Voltage of Power Supply:

|

22V-380V,50HZ

|

|

|

|

||||

|

Total Power

|

25kw

|

|

|

|

||||

|

Machine Weight

|

13.5T

|

|

|

|

||||

|

Color of Machine

|

White Plus Gray&Yellow

|

|

|

|

||||

|

Machine Dimension:

|

26500mm*2200mm*2250mm

|

|

|

|

||||

|

12 mm thick Steel Slates for The Whole Machine (The machine is plastic sprayed.)

|

|

|

|

|

||||

|

Air Supply

|

Auxiliary Device

|

|

|

|

||||

1. This machine is designed for making mailer bags after the kraft paper and the online bubble paper or the honeycomb paper or

the corrugated paper are glued together by water and hot heat glue.

2. Bag making method: three rolls of kraft paper are put into the release frame, the middle layer of kraft paper is in the

middle of the three release frames for pressing bubble, bubble paper or honeycomb paper or corrugated paper is fixed in the

middle layer of two layers of kraft paper by way of fixed point spraying glue, after longitudinal and horizontal pressing,

then horizontal secondary spraying glue, folded and sealed by hot pressing and then cut into an environmental protection buffer

packaging bag with buffer function for express delivery.

3. The machine adopts advanced motion control technology, from material unwinding to cutting and forming, all controlled by

computer, the paper bags produced are flat and environmentally friendly, the sealing is strong and reliable, simple to operate and

easy to understand, it is a high-quality special bag-making equipment.

4, The machine can also produce: honeycomb mailer bags, Corrugated cardboard mailer bag, Embossed paper bubble mailer bag as

below.

Features of Honeycomb envelope bag conversion line

1, Adopts advanced motion control technology, from unwinding to cutting forming, are controlled by computer

2, Automatic Machine controlled by PLC and Inverter. Easy operation control panel.

3, Parameter setting effect immediately, tracked by electronic eyes, smooth and accurate.

4, Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and

pick up motors make production more productive.

5, It is very easy to load and unload products with air shafts in the rewinding and unwinding parts

the corrugated paper are glued together by water and hot heat glue.

2. Bag making method: three rolls of kraft paper are put into the release frame, the middle layer of kraft paper is in the

middle of the three release frames for pressing bubble, bubble paper or honeycomb paper or corrugated paper is fixed in the

middle layer of two layers of kraft paper by way of fixed point spraying glue, after longitudinal and horizontal pressing,

then horizontal secondary spraying glue, folded and sealed by hot pressing and then cut into an environmental protection buffer

packaging bag with buffer function for express delivery.

3. The machine adopts advanced motion control technology, from material unwinding to cutting and forming, all controlled by

computer, the paper bags produced are flat and environmentally friendly, the sealing is strong and reliable, simple to operate and

easy to understand, it is a high-quality special bag-making equipment.

4, The machine can also produce: honeycomb mailer bags, Corrugated cardboard mailer bag, Embossed paper bubble mailer bag as

below.

Features of Honeycomb envelope bag conversion line

1, Adopts advanced motion control technology, from unwinding to cutting forming, are controlled by computer

2, Automatic Machine controlled by PLC and Inverter. Easy operation control panel.

3, Parameter setting effect immediately, tracked by electronic eyes, smooth and accurate.

4, Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and

pick up motors make production more productive.

5, It is very easy to load and unload products with air shafts in the rewinding and unwinding parts

Product Description

Hot Searches