NaN / 0

Polyisocyanurate Foam PIR Cold Room Insulation Sandwich Panels/Boards

Get Latest Price

US$ 30

≥2 Square meters

US$ 20

≥10 Square meters

Quick Details

Project Solution Capability:

total solution for projects, Others

Application:

Storage & Closet

Design Style:

Traditional

Place of Origin:

Jiangsu, China

Product Details

Client Feedback

Product Description

Advantages of PIR sandwich panel

1) Excellent fire test performance (B1 grade fire-resistance)

2) Superior R-Value and thermal performance

3) Moisture resistance

4) Dimensionaly stable

5) Unaffected by commonly used construction adhesives and solvents

6) Building code conformance

|

Specification &

Technical Standard

of PIR sandwich panels

|

|

|

|

|||

|

Width

|

Standard width 1120mm,

|

|

|

|||

|

Length

|

As customers' requirements.

|

|

|

|||

|

Thickness

|

50/75/100/150/200/250 mm

|

|

|

|||

|

Surface material

|

Color steel/stainless steel/embossed aluminum/ anti-slip aluminum

|

|

|

|||

|

Core material

|

PIR(polyisocyanurate)

|

|

|

|||

|

Joint system

|

slip-joint

|

|

|

|||

|

Density

|

45±2 kg/m3

|

|

|

|||

|

Heat Conductivity

|

≤0.022 W/m. k

|

|

|

|||

|

Compressive Strength

|

≥160 N/cm2

|

|

|

|||

|

Combustion performance

|

B1 grade

|

|

|

|||

|

The bond strength between sandwich core layer and panel

|

>0.1

|

|

|

|||

Drawing

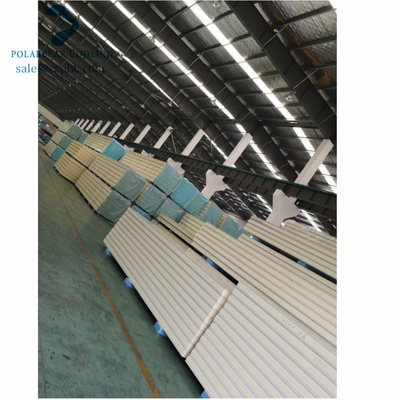

Project Display

32 meters high logistics warehouse

mushroom cultivation room

slaughter cold room

Packing & Delivery

Packaging Details.

1) Free packing (with normal pallet and packing belt).

2) Standard exporting packing

Delivery time.

1) Off season lead time: 7days

2) Peak season lead time: 15days

Our Company

We was founded in 1996. Our company is a first-class cold storage insulation materials manufacturer and a cold storage energy-saving program supplier. We focus on the field of cold storage materials and cold storage research and development areas, through years of great-leap-forward development, the company is expanding, now has 28 management staff, 15 technical staff and 170 engineering installation and production staff. The company has established two production bases, covers an area of more than 80 acres, adopt the most advanced in domestic and international third-generation automatic continuous production line, which improves the capacity of production and supply for various types of products. At present, the annual output of our company is thermal insulation materials up to 1.5 million square meters, all kinds of cold storage doors 8, 000 sets, industrial unloading platform 1, 500 sets, all-round to meet the various needs of customers.

Related Products

Contact Us

Hot Searches