NaN / 0

FR-50 High precision cheese Pipe Straightener machine for metal tube and wire straightening machine

Get Latest Price

US$ 8000

≥1 Pieces

US$ 7800

≥2 Pieces

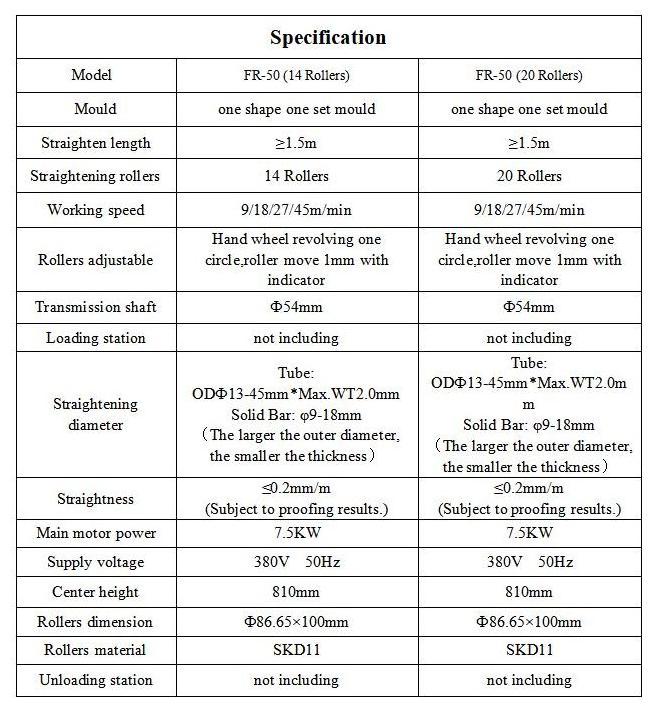

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

Fangrong

Voltage:

380

Power:

7.5kw

Product Details

Products Description

Description of Straightening Machine

The straightening and calendering machine produced by our company is a high-tech equipment with independent intellectual property rights developed by bold innovation on the basis of absorbing and digesting foreign advanced technology and combining with the specific conditions of domestic enterprises. The technology has reached the domestic advanced level, and the efficiency is several times higher than that of the conventional process. Reliable performance, high quality and low price.

The product is suitable for processing various metal materials, such as structural steel, alloy steel, spring steel, bearing steel, tool steel and other ferrous metal materials; copper and copper alloys, aluminum and aluminum alloys, magnesium alloys, titanium and titanium alloys and other non-ferrous metal materials. For metal pipes and rods, such as alloys, stainless steel, carbon steel, copper alloys, titanium alloys, nickel, magnesium alloys, molybdenum, etc.

Straightening machine is mainly used for precision straightening and calendering of peeled or ground metal bars. Since its straightening and calendering are done at one time, the work efficiency is high.

Advantages of Straightening Machine

NO indentation on the surface of the workpiece,

Rounding function

NO bending at both ends of the workpiece. (Assume that the roundness of the workpiece after extrusion is 0.2mm, and the roundness after straightening can reach 0.1mm-0.12mm)

Details Images

Customer Cases

Application Field

Widely used in copiers, printers, rollers, sports equipment, furniture, aviation, automotive industry, electrical accessories, electronic products, medical equipment, machining.

Packaging & Shipping

Hot Searches