NaN / 0

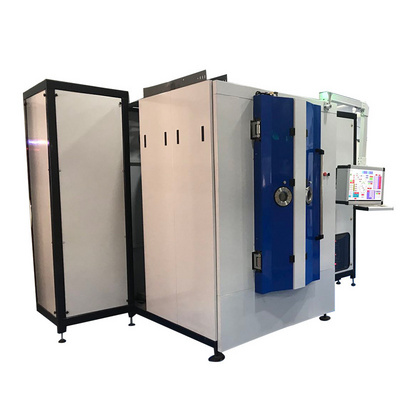

Pilot Vacuum Plating Silver Thin Film Deposition Magnetron Sputtering System

Get Latest Price

US$ 80000

≥1 Sets

Quick Details

Machine Type:

PVD coating machine-Magnetron Sputtering, Coating Equipment

Place of Origin:

Hunan, China

Brand Name:

Hongfeng PVD Machines

Voltage:

Customers Local Voltage

Product Details

Vacuum Plating Silver Thin Film Deposition Magnetron Sputtering System

The equipment is a reasonable structure, coating evenly into good-quality, pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability. Widely used in automotive, audio and various small appliances, computers, clocks and watches, toys, cell phones, reflective Cup, cosmetics, toys and other industries.

MF Sputtering

DC magnetron sputtering coating machine is usually used for direct sputtering coating for different substrates, such as kinds of plastic, glass, metal, ceramic, etc.

We have dedicated more than 10 years to manufacturing and designing magnetrons that can be rectangular, cylindrical, circular, and of various sizes. They have developed a plethora of targets that can be directly cooled or bonded, and can be manufactured in such a way that can fit most magnetron sizes.

Magnetic fields can essentially define the behaviour and the properties of the ion charged particles that are used for sputtering. The development and commercialisation of software that can enable the distinct modelling of magnetron sputtering is bound to enhance its productivity, applicability, and reproducibility.

| T echnical Spcifications |

| Model Number | SP-1000 | SP-1200 | SP-1400 | SP-1800 |

| Dimension of vacuum chamber | 1000*1100 | 1200*1400 | 1400*1600 | 1800*2000 |

| (diameter*height) | ||||

| Material of vacuum chamber | Carbon steel, SUS304 or SUS316L | |||

| Quantity of sputtering cathodes | ≥1 sets, DC sputtering system, cylindrical or rectangle sputtering cathodes | |||

| Pumping system | Turbo molecular pumps or diffusion pump+mechanical pump | |||

| Pumping Time | From atmosphere to 5.0*10-2Pa less than 8 minutes | |||

| Gas distribution System with Mass Flow Controllers | ≥2 sets | |||

| Ultimate Vacuum | 5.0*10-4 Pa | |||

| Working temperature | Room temperature | |||

| Working mode | Automatic or Manual mode, by 10.4(or 15) inches PLC touches screen | |||

| Total Power | 40-100kW | 70-1000kW | ||

| These units you can custom made | 1. Size of vacuum chamber | |||

| 2. Quantity of sputtering cathodes | ||||

| 3. Configurations of pumps | ||||

| 4. Gas distribution system | ||||

| Optional instruments | 1. Coatings thickness monitor | |||

| 2. Leakage detector | ||||

| 3. Arc ion deposition system(not for continuous model) | ||||

| 4. Evaporation system(not for continuous model) | ||||

PS: All the specifications can be customized according to your requests.

You will need some necessary parts for daily production, we can also provide:

· Vacuum pumps

· DC sputtering cathode with power supplies

· Unbalanced sputtering cathode with power supplies

· O rings

· Vacuum meter with gauges/sensors

· Bias power supply

· Magnetic valves

· MFC

· Target materials

· Customized jigs

Hot Searches