NaN / 0

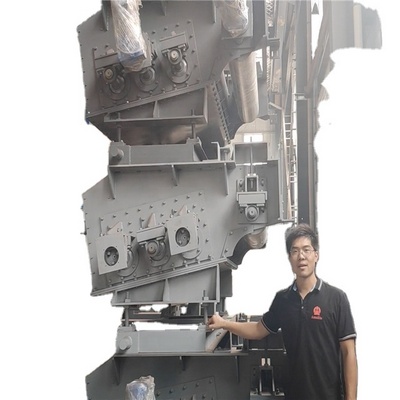

precast concrete fence post moulds machine for T L beam moulding making machine of Precast Concrete Wall Panel

Get Latest Price

US$ 12500

≥1 Sets

Quick Details

Type:

Interlock Block Making Machine, eps cement sandwich panel lightweight cement panel

Brick Raw Material:

CONCRETE

Production Capacity (Pieces/8 hours):

1500 pcs/8hours, 3000 pcs/8hours, 800 pcs/8hours, depend on your need

Brick size:

2440*610mm

Product Details

Use the advantages of EPS light weight wall panel . Wall Panel Machine Wall Panel Production Line Prefabricated Wall Panels Making Machine

Using precast reinforced HONGFA EPS Panels reduces the overall construction cost in many ways in a project. Being easy to install and light weight it increases the construction speed and reduces the construction time drastically, resulting into huge reduction in the labor cost. HONGFA EPS panels are a light weight material and can be used anywhere in different soil conditions. As the dead weight of the panels are very low compared to normal construction it is suitable in low dead weight bearing soils as the superstructure is lighter reducing the material requirement in the foundation ultimately reducing the construction cost. Since the walls and partitions are lightweight the beams and Pillars size will be reduced finally further saving the cost of the project. The walls of HONGFA EPS Panels compared to normal walls are more comfortable for the inhabitant in terms of heating and cooling. EPS has a very low thermal conductivity value, in the range of 0.032-0.035W/(m•K), therefore in summer it keeps the interior cooler and in winter in keeps the building warmer by preventing the external effect of the environment resulting into saving the energy requirement for heating or cooling up to 60-80%. It has very good sound insulation for peaceful indoor environment.

What are the EPS concrete light weight wall panel

As a new type of high-grade light weight wall panel material with EPS mortar as core material, and calcium silicate board as the surface material, the light weight EPS wall panel, also called compound sandwich wall panel, precast wall board and panel, etc. The EPS concrete sandwich wall panel is properly made by cement, sand, fly ash and other materials and additives, and it is a new developed wall building material which is in recent years and now is popularly wide used around the world in the construction filed.

According to the relevant institutions, the new kind of lightweight concrete EPS wall panel has been proved to be sound insulation, fire resistant, radioactive, and water resistance.

The raw materials to make EPS concrete lightweight wall panel.

When considering a building project, to reach high return of investment, the easy touch of raw material is an important factor. The production of EPS concrete lightweight wall panel must be rich and extensive sources of raw materials. The main raw materials of wall panel are industrial residues, fly ash, sand slag and EPS foam particles, which is recyclable and reducing pollution. The above two kinds of sources of raw materials are abundant and extensive.

Advantage of the plastic EPS sandwich panels board

A:Light weight

B:Excellent sound insulation

C:Heat Insulation

D:Waterproof Fire proof

E:Energy Efficient Environmental

F:Convenient construction

G:High Intensity without deformation.

:

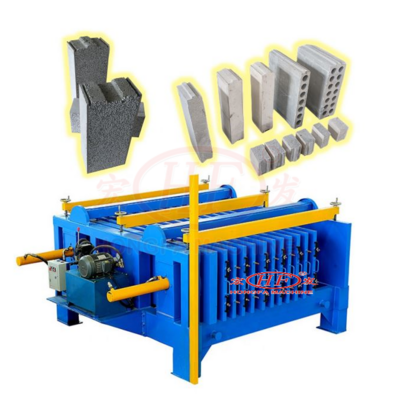

1: Horizontal type EPS wall board forming machine: high level of automatic operation,fewer workers required.

| Horizontal Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 2750x2504x1359 mm | 3kw | 16pcs | 14pcs | 12pcs | 12pcs | 10pcs | 8pcs |

2: Automatic vertical type:

automatic operation,high output,fewer workers required.

HONGFA Panel Making Machines EPS Concrete Sandwich Panel Machine EPS Styrofoam Foam Cement Board Wall Panel Machine EPS concrete solid panel & hollow panel, gypsum panel, foam panel. It can be with or without calcium silicate board and fiber cement board.

| Automatic Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3380x3200x2680 mm | 4kw | 40pcs | 36pcs | 32pcs | 30pcs | 26pcs | 22pcs |

3: Manual vertical type partition wall board making machine:

Manual operation,the highest output amount the three types, but requires more workers.

| Manual Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3600x1320x2800 mm | no | 58pcs | 50pcs | 42pcs | 40pcs | 34pcs | 28pcs |

How are the land,water,power required to set up an EPS light weight wall board production line?

Water

requirement

s

:

to produce

60

m

2

panel

(9 cm thick

ness as

example) required

one

ton of water. No special requirements for water quality,

clean

water can be used for production.

E

lectricity requirement: installed power 30 kw (depending on the capacity).

Requirements on air and steam

:

Air compress

or and boiler.

Land requirements

: 1200-200

0

m

2

workshop

and

9 meters

high

(depending on the capacity).

Other Main Machines for Complete Production Line

1. Mixing plant

HONGFA mixing plant consists of mixer, movable infusion unit and aggregating system. It can mix all raw material automatically and record every data for production. 3.6CBM capacity mixer guarantees infusion efficiency. It only needs about 15seconds to finish a panel with size 2440*610*100mm.

2. EPS Expander

EPS expander is used for expanding raw polysterene, one-time expander can make EPS around 15-18kg/CBM, interval expander can get proportion on 9-11kg/CBM.

3. De-molding machine

De-molding machine can pull the cured panels out deirectly, Hongfa design it based on 6 years panel manufacturing experience, make it possible that demolding machine is movable, after demolding, the molds can be installed immediately without any delay.

Multiwork is possible so efficiency is triple compared to traditional vertical manual and semi horizontal production line.

4. Recycling unit

Recycling unit can save eveything in production, waste slurry settling in underground mixer, the cement and sand will be pumped into mixer again for next mixing cycle. Keep production clean and make waste recycling, cost saving.

5. Hollow core panels unit

If you want hollow core wall panels with thickness above 150mm, HONGFA offers complete system solution. Hollow panels usually use for roof, cladding etc. purpose without any bearing demand.

6. Movable slurry piston pump unit

This unit uses for movable hydraulic slurry infusion, after mixing all raw material in mixer, then slurry pours into this movable container, it can mix and inject at same time, guarantee slurry not falling down or the heavier material(sand or cement) seperates from lighter(EPS) one.

Some of succeed case .......

Packaging & Shipping

Package & Delivery

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 40 days after receipt of deposit and moulds confirmation from buyer

Hot Searches