NaN / 0

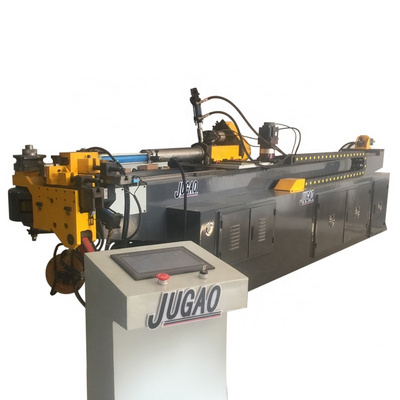

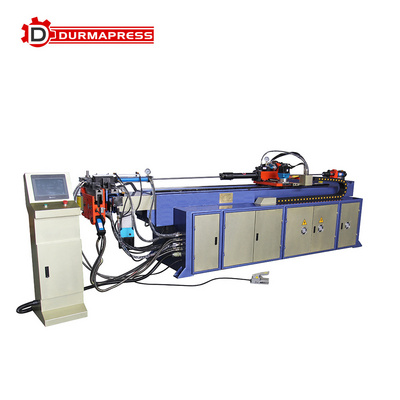

Copper Aluminum Iron Stainless Steel Round Rectangle CNC Hydraulic pipe bending machine Auto Exhaust Pipe Bender

Get Latest Price

US$ 18000

≥1 Sets

US$ 17800

≥2 Sets

Quick Details

Max. Bending Angle (Deg):

190

Bending Precision (Deg):

1

Place of Origin:

Jiangsu, China

Power (kW):

2.2

Product Details

Copper Aluminum Iron Stainless Steel Round Rectangle CNC Hydraulic pipe bending machine Auto Exhaust Pipe Bender

Product Description

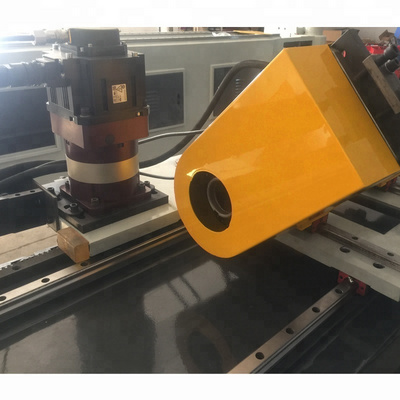

- Bend-arm (C-axis) by hydraulic. Clamp die by hydraulic, Pressure die by hydraulic.

- Carriage (Y-axis) by servo motor. Collet (B-axis) : rotation by servo motor, grip by hydraulic.

- Anticipated mandrel retraction unit. Standing pedestal, serves emergency stop and remote control.

- Fan-cooling system. Diagnosis error immediately.

- Central Automatic lubrication system.

- Foot pedal for safe start.

- It is fully automatic pipe bending machine, with PLC control system, two servo for rotary, feeding.

- Touch screen panel display English, have different bending degree prefabricate, dialogue operation, can choose manual, semi-automatic and full automatic operation manual, portable pedal switch with start and emergency stop function.Multi axes working simultaneously.

- Bending pipe — Automatic. Rotating pipe — Automatic. Feeding pipe — Automatic. 10. One key back up of programs for USB or disk storage or through INTERNET. Management and storage of bend data and tools is done in standard text files on the hard disk of the control PLC. In case of requirement it is also possible to integrate the PLC into bending machine. Therefore an Ethernet adapter is included. The number of tools and products is practically unlimited. Product and tool files can easily be edited (also on a separate PLC) and printed out.

- Security code for the protection the data setting and selected operation features. 12. To access to the history bending setting data to the facilitate study of malfunction with one set of tooling.

- All the parts of hydraulic system, control system, driver system and display system are imported from famous brand, with high accuracy, high efficient, suitable for mass production.

- CNC fully auto, have cubical space bending equipment, loading the whole bending process is automatic.

- The machine is convenient operation, stable performance and high safety factor. The machine is the ideal choice for the pipe processing.

Standard accessories

1. One pair of standard mould (wheel mould, clamping mould and sliding plate mould)

2. One set of common tools

Optional accessories

- Industrial Computer Controlling

- Anticipate Mandrel Extraction

- Automatic mandrel/machine lubrication

- Anti-clockwise bending direction

- Machine effective length over mandrel

- Safety Mat

Categories of bent materials

Steel tube, stainless steel tube, copper tube, aluminum tube and multiple-unit tube

Shapes of bent materials

Round tube, square tube, elliptical tube, plum blossom-shape tube, shaped tube, U-steel, angle steel, I-steel and flat steel, etc.

Recommended using units

Automobile spare parts (brake line, bumper bar, silencer and seat, etc.). Industries including motorcycle manufacturing, electromobile manufacturing, iron art, fitness equipment, air conditioning, bicycle, steel furniture, sanitary and bathroom equipment, seats for relaxation, petroleum pipeline, shipbuilding and boiler.

Technical parameter

| Main Technical Parameter | Unit | 18CNC | 28CNC | 38CNC | 50CNC | 63CNC | 76CNC | 89CNC |

| Max. Bending Capacity | mm | 18×2 | 28×2 | 38×2 | 50×2 | 63×4 | 76×5 | 89×6 |

| Bending Radius Region | mm | 3-150 | 5-180 | 10-200 | 15-250 | 20-300 | 25-350 | 40-450 |

| Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

|

Effective Length Over Mandrel |

mm | 1500 | 2800 | 3200 | 3500 | 4000 | 4200 | 4600 |

| Oil Pressure System Motor | kw | 2.2 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 11 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Machine Dimension | mm |

3000×700 ×1300 |

3500×750 ×1300 |

4200×950 ×1350 |

4800×1000 ×1350 |

5200×1100 ×1350 |

5800×1200 ×1350 |

6200×1500 ×1350 |

| Main Technical Parameter | Unit | 114CNC | 129CNC | 140CNC | 168CNC | 219CNC | 273CNC | 325CNC |

| Max. Bending Capacity | mm | 114×8 | 129×8 | 140×10 | 168×12 | 219×16 | 373×18 | 325×18 |

| Bending Radius Region | mm | 40-550 | 50-650 | 50-650 | 60-850 | 80-1200 | 150-1300 | 200-1500 |

| Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

|

Effective Length Over Mandrel |

mm | 4800 | 5200 | 5800 | 6000 | 6500 | 6800 | 7500 |

| Oil Pressure System Motor | kw | 15 | 18.5 | 22 | 22 | 30 | 55 | 55 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Machine Dimension | mm |

6800×1650 ×1350 |

7200×1800 ×1350 |

7500×1850 ×1550 |

8800×2000 ×1550 |

9500×2100 ×1350 |

10000×2200 ×1850 |

12000×2300 ×1850 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

Hot Searches