NaN / 0

ATOP DLC PVD Coating Machine

Get Latest Price

US$ 120000

≥1 Sets

Quick Details

Machine Type:

vacuum coating machine

Place of Origin:

Jiangsu, China

Brand Name:

ATOP

Voltage:

380V

Product Details

Product Description

Application Field

DLC PVD Coating Machine

Main Feature

1.Plasma source assisted deposition technology,pre-cleaning and the auxiliary deposition to the work piece.

2. Adopt the high power pulse bias power supply enhance the coating adhesion.

3. Adopt multiple sets of twin arc,which can install 2-6 different target materials.Pure metal or alloy composite nano film layer is achieved.

4.The work piece rack adopts rotation and revolution structure,large loading capacity and temperature resistance.The frame can move out of the chamber which is convenient to load heavy molds.The work piece rack can be customized according to customer requirements and adopts inverter to adjust,and infinitely adjustable speed.

5. The touch screen and PLC.This machine can realize automatic control,automatic and manual switch.

Our Company

ABOUT US

Vacuum coating is the major business of Atop Industry Co.,Ltd, We have more than 20 years of experience in the industry, our factory has obtained ISO quality management system and CE certificate. 100% Strictly carry on the design, production and testing to each equipment under ISO9001: 2008 quality management system, which ensures the stability and high quality products providing to tens of thousands of customers use.

Our main products include continuous magnetron sputtering coating production line (SIO2, ITO, AZO, TCO, low-e) plane arc tooling coating machines , multifunctional intermediate frequency magnetron sputtering coating equipment, Multi-arc compound ion coating machine, optical coating machine and ion plating technology, including : unbalanced magnetron, intermediate frequency magnetron sputtering and arc evaporation source, ion source auxiliary coating and the combination of a variety of technical features. The rolling coating machine which takes the high frequency induction evaporation technology can satisfy the PET, PVC, OPP, CPP strip material, laser holographic anti-counterfeiting materials such as film, capacitors, polyester cloth and other vacuum aluminum plating and evaporation of the medium material requirements.

UP to now, our company has been serving more than thousands of customers widely in solar photovoltaic (PV), low radiation coated glass, flat panel display, semiconductor, light, hardware clock, mold, electron, food, plastics and other industries.

With stable-quality, high-efficient products and excellent customer service , Atop Industry Co.,Ltd has gained great reputation from more and more domestic and foreign customers!

Turnkey Service: including film research and equipment research, manufacturing, installation, debugging, trial production, personnel training. our company has perfect after-sales service network and more than 10 individuals experienced after-sales service team, all-round for customers solve various problems of vacuum equipment and process.

Packing & Delivery

PACKAGE:

Packed in standard export packing.

DELIVERY TIME:

Delivery:

45-70 days after the day of deposit payment (except holidays).

Machine acceptance inspection: we will inform the customer the test date of the machine within the delivery date. The customer can arrange the exact date to our workshop to inspect the machine. When the machine passing by the inspection, the customer pay the balance payment and we will transport the machine to Shanghai Port.

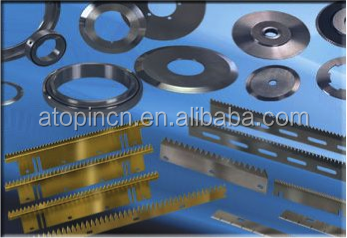

Customer Photo

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

Q: How much is the price of DLC PVD Coating Machine?

A: Our products are customized, please tell us you requirements and configuration of the product, the price varies greatly for different configuration.

Q: How long is your delivery time?

A: Generally 45-70 days after deposit

Q: How much is the MOQ?

A: MOQ is 1 set

Q: What is your terms of payment ?

A: T/T with 30% deposit, 70% before delivery.

Related Products

Hot Searches