NaN / 0

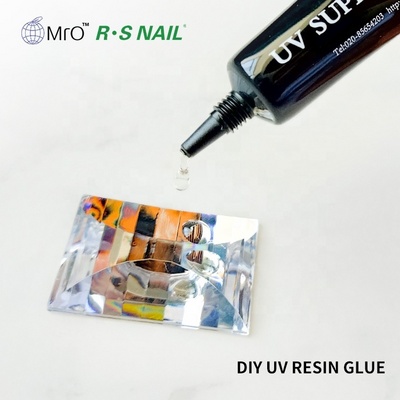

universal clear uv curing resin,all-purpose epoxy resin uv adhesive for diy & jewelry crystal uv glue

Get Latest Price

US$ 28.5

≥1 Kilograms

Quick Details

CAS No.:

25133-97-5

Other Names:

UV Adhesives

MF:

75980-60-8

EINECS No.:

5888-33-5

Product Details

universal clear uv curing resin,all-purpose epoxy resin uv adhesive for diy & jewelry crystal uv glue

Product Description

our product Free of solvent, TOL and HCHO, environmental, no harmful for people,No BATO,TPO and TPO-L.

MOQ: 1kg

The product is uv curable glue that cures in 200 ~ 400nm wavelength ultraviolet ray. It is mainly used in dry require effect of plastic and plastic, plastic and glass, plastic and metal materials such as bonding occasion. Aimed at selfadhesive plastic handicraft industry, and crossstick, the main bonding of plastic are: PMMA (acrylic, plexiglass), PC, ABS, PVC, PS and other thermoplastic.

Feature

· General products have a very broad scope application, plastic with a variety of materials have excellent adhesive bonding effect.

· Flexible formula, after curing it will not be stress cracking , low temperature, high temperature and humidity performance, Excellent.

· Curing quickly, few seconds can be positioned, one minute to reach the highest intensity, which greatly improves work efficiency.

· Completely transparent after curing, the product unchanged yellow and whitening for long timeCompared with the traditional instantaneous Adhesive bonding, with resistance to ring measurement, non-whitening, flexibility and good.

Specifications

|

Test project |

3350 |

3351 |

3352 |

|

appearance

|

clear liquid |

clear liquid |

clear liquid |

|

Viscosity mpa.s |

700-1000 |

4000-5000 |

10000-13000 |

|

position time |

2 |

5 |

5 |

|

Curing Energy mj/cm² |

1500 |

1500 |

1500 |

|

the tensile strength between acrylicwithacrylic (MPa) |

>14 |

>14 |

>14 |

|

the tensile strength between acrylicwith glass(MPa) |

>14 |

>14 |

>14 |

|

the tensile strength between acrylic with metal (MPa) |

>13 |

>13 |

>13 |

|

|

|

|

|

|

|

|

|

|

|

Hardness (ShaoD) |

>70

|

>50

|

>52 |

|

the transparency of after curing

|

high transparency

|

high transparency

|

high transparency

|

|

feature

|

Low-viscosity, dry quickly, have a greater variety of plastic adhesion |

In viscosity, have a greater variety of plastic adhesion |

High viscosity, for a variety of plastics have a greater adhesion |

The positioning time of the above that is under glass and glass bonding in 40-watt Philips intensity of 7.5 mW/cm2 uv light condition measured.

the way of using

First, clean the materialsurface, dry the surface, and wait for the fully dried before dispensing.

Second, The glue uniform point (down) in which material surface, and the other piece material placed on the glue Department to conduct light fitting, forced discharge, and squeeze the glue leveling bubble to determine the bonding sites are covered by the glue and fixed a good position.

Third, use a wavelength of 365 nm ultraviolet light to carve, until the layer has fully cured. Ultraviolet light irradiation is as close as possible to accelerate the curing speed glue.

Fouth, after ultraviolet radiation curing, you can resin the gel of the glass around curettage.

Notes

1. The ideal thickness of bonding layer is 0.01-0.05mm, if too thin or too thick, it will be affected to the adhesion properties.

2. Ensure that the adhesive layer to absorb enough ultraviolet energy in order to achieve the best curing effect, or possibly to influence adhesion layer.

3. Not back and forth movement of the glass, otherwise easily led to layer whitish and bonding strength decreased.

4. Residual glue can not be pumped back into the original packaging, should be stored at sealed dark room temperature and without rendering children.

Storage

Storage in the dark, sealing, ventilation, cool conditions, the ideal storage temperature is 8-28 .

Duration: 1 year

Packaging

250g/bottle,1 kg / bottle, 20 kg / barrel

APPLICATIONS

OEM Service

For OEM customers: if without your ideal bottles in below packing, contact us freely. I will send you more according to your request.

Hot Searches