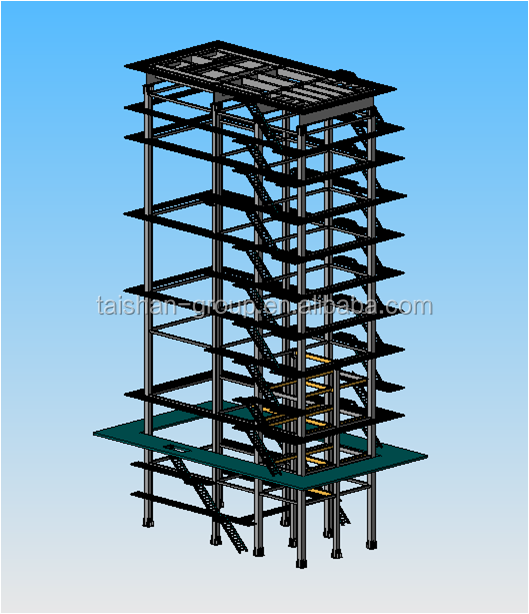

ØThree parts: 1. Roof system, 2. Beam, column and support system 3. Platform and ladder system

ØThe platform width is 0.85m or 1m.

Ø The ladder width is 0.7m,inclination angle 45°

Ø The handrail and baluster adopts

Øgalvanized tube, size is Φ1

ØThe baluster pitch is 1~1.2m

Ø The handrail height 1.2m