NaN / 0

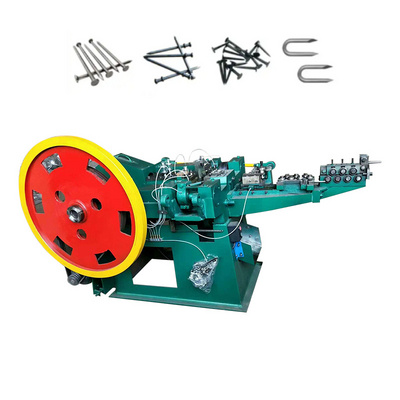

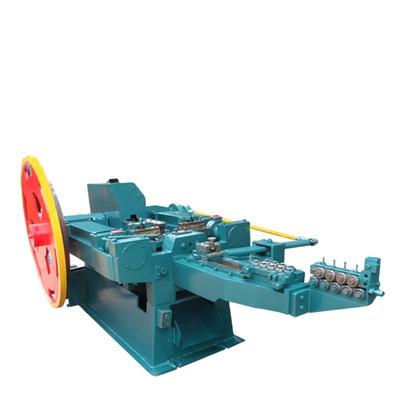

Best price High speed Automatic steel iron wire nail making machine

Get Latest Price

US$ 1950

≥1 Sets

Quick Details

Production Capacity:

360pcs/h

Core Components:

used wire nail making machine

Place of Origin:

Henan, China

Brand Name:

HS

Product Details

Product Description

High speed Automatic steel iron used wire nail making machine is mainly used to manufacture various specifications of steel nails. If slightly modified, other special steel nails can be manufactured, such as oil blanket nails, V-nails, U-nails, corrugated nails, shooting nails, gun nails and so on. The steel nails can be widely used in industry, construction and repair. The main design of the machine refers to the design of similar high-precision products in West Germany, and adopts the domestic and foreign customers. According to the principle of advantageous use and operation, a new generation of automatic nail-making machine has been developed independently. The equipment has beautiful appearance, smooth lines, scientific and reasonable structure, and the clearance adjustment of the central slider adopts the iron-type adjustment, which makes the operation and maintenance more convenient. The lubrication adopts the automatic oil supply system, making the work more stable and reliable, and the noise greatly reduced (about 10 points). Beibei) greatly improved working conditions and reduced the restrictions of specifications of various models, which can effectively reduce the investment cost of investors. Once the nailing process is fully automated, high quality steel nails can be continuously produced once they are started.

High speed Automatic steel iron used wire nail making machine is mainly used to manufacture various specifications of steel nails. If slightly modified, other special steel nails can be manufactured, such as oil blanket nails, V-nails, U-nails, corrugated nails, shooting nails, gun nails and so on. The steel nails can be widely used in industry, construction and repair. The main design of the machine refers to the design of similar high-precision products in West Germany, and adopts the domestic and foreign customers. According to the principle of advantageous use and operation, a new generation of automatic nail-making machine has been developed independently. The equipment has beautiful appearance, smooth lines, scientific and reasonable structure, and the clearance adjustment of the central slider adopts the iron-type adjustment, which makes the operation and maintenance more convenient. The lubrication adopts the automatic oil supply system, making the work more stable and reliable, and the noise greatly reduced (about 10 points). Beibei) greatly improved working conditions and reduced the restrictions of specifications of various models, which can effectively reduce the investment cost of investors. Once the nailing process is fully automated, high quality steel nails can be continuously produced once they are started.

| parameter | unit | Z94-5.5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

| Dia of nail max | mm | 5.5 | 4.5 | 3.4 | 2.8 | 1.6 |

| Dia of nail min | mm | 3.7 | 2.8 | 1.8 | 1.2 | 0.9 |

| Length of nail max | mm | 150 | 100 | 80 | 50 | 25 |

| Length of nail min | mm | 80 | 50 | 30 | 16 | 9 |

| Dsigned out put | pcs/min | 200 | 260 | 320 | 350 | 450 |

| Moter power | kw | 5.5 | 4 | 3 | 2.2 | 1.5 |

| Weight(approx) | kg | 2500 | 2000 | 1400 | 1200 | 560 |

| Overall dimensions | mm | 2800x1800x1800 | 2200x1600x1650 | 2000x1400x1400 | 1700x1300x1400 |

1500x1300x1200

|

Packaging & Shipping

Package and Delivery

Transportation:by ship or by air

Our Services

1.Help you choose the most suitable machine.

2.customize the machine according to your request.

3.give you machine's details and video for help you use the machine more better.

4.Normally the service life of our machines can be 3-5 years.

5.We offer full set of easy-spoiled spare parts and tools for back up.

6.We can send our engineer abroad to training customers to operate the machine.

7.Normally we can resolve any problem online together with our customers.

Hot Searches