NaN / 0

0.2mm-3mm Geomembrane Overlap Hot Wedge Geomembrane Welding Machine

Get Latest Price

US$ 650

≥1 Pieces

Quick Details

Place of Origin:

Shandong, China

Brand Name:

BPM

Voltage:

220V

Frequency:

50HZ

Product Details

BPM900 Geomembrane Overlap Hot Wedge Welding Machine

welding machine is our new developed products, which can weld geo-membrane of various thickness and are applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and so on.

The control of this series of welding machine adopts PID automatic thermostatic control with high control accuracy and low temperature fluctuation; speed control adopts PWM automatic voltage and speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable. It can maintain a constant speed on the condition of creeping, vertical creeping and variable road load. Also this series of welding machine is stable in performance despite of external temperature and voltage variation.

This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on .

2. Precautions

1). For correct operation, please carefully read this instruction.

2). Use with grounded 3-cords mains cable and socket (socket with 10A capacity. On the corresponding welder, phase L connected to live wire, N to zero line, phase to grounded protection line), plug will not be modified without prior permission.

3). For good welding quality, please assign specified personnel for operation.

4). Pressure roller will not engage on free running.

5). Do not operate when it is exposed to water to prevent inferior quality.

6). The machine has been regulated before leaving factory. Please do not adjust it at will.

7). Circuit board in control box is electrified. Do not remove it without prior notice to authorized personnel.

8). Preheat for 30 minutes before start up if machine has been long unused or exposed to moisture.

9). Modifications may be made for continuous improvement, without prior notice .

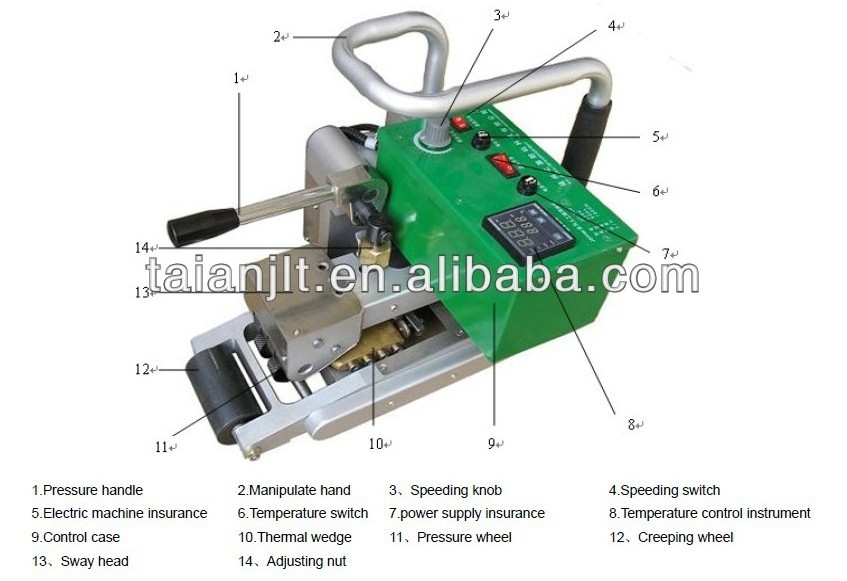

3.Operation principle

Motor drives upper and lower pressure rollers to rotate through reduction gearbox and chain. Slide carriages drive the hot wedge and insert it between the two base materials, at the same time lever presses pressure rollers and engages the two fused base materials .

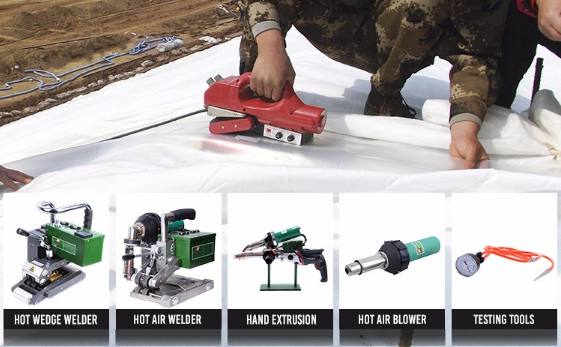

More Equipment for your choice:

| Product | Specification | image | technical parameter | N.W | ||

| Welding Equipment for 0.2mm-1.0mm | BPM800 |

Power: 800W

Design welding Thickness:0.2mm-1.0mm Welding speed: 0.8-6m/min Heating temperature: 0-450℃ Welding thickness: 0.2mm-1.0mm Overlap width: 100mm |

8kg | |||

| BPM1600A |

Power:1600W

Design welding Thickness:0.2mm-1.0mm Frequency:50/60 Hz Temperature:20~700 ℃ Noise level:65 db |

2kg | ||||

| Welding Equipment for 1.0mm-2.0mm | BPM900 |

Power:1800W

Design welding Thickness:1.0mm-3.0mm Welding speed:0.5~5m/min Heating temperature:0~450℃ Welding thickness:1.0mm~3.0mm Joint width:120mm |

18kg | |||

| BPM610B |

Design welding Thickness:1.5mm-4.0mm

Power: hot air welding torch 3400W Extrusion temperature: 0 ~ 450 ℃ Welding rod diameter: Φ3.0mm ~ 4.0mm Welding Speed 2kg/h |

15kg | ||||

Application:

- Welding of thermoplastic materials as well as single-ply flexible plastics and modified bitumen in the form of boards, tubes, profiles, lining membranes, coated materials, films, foams, tiles and sheets. The following procedures are possible: overlap welding, welding with rod, with tape, butt welding and melt welding.

- For foaming, ending and sealing of the thermoplastic semi-finished materials and plastic granules.

- Drying of water-damp surfaces.

- Shrinking of heat-shrink sleeves, films, tapes, solder sleeves, preformed and mould part.

- Soldering of copper pipes, solder joints and metal foils.

- Defrosting of frozen water pipes.

- Activating and dissolving of solvent free adhesive and fusion adhesives

- Igniting of wood shavings, paper, coal or straw in furnaces

Readiness of working:

- Fit appropriate nozzle as required

- Connect tool to the line/mains

- Adjust air temperature

- Switch on main switch and heat up the tool for approximately 5 minutes.

Changeable nozzles:

- Do not touch the hot nozzle and make sure to place it on a heat resistant surface because of the fire hazard..

- Put the nozzle on the heater tube and secure the nozzle by the screw on the cap.

- Use nozzles only.

Maintenance:

- Clean polluted air filter with a small brush or replace it

- Clean welding nozzle with a steel brush.

- Check mains cable and plug for electrical and mechanical damage.

Service and repairs:

- The motor switches off automatically when the brush reach their minimum length. Have the tool checked by your service center. The life of the brushes is about 800 hours.

- Repairs should be carried out by authorized service centers only. They guarantee a specialized and reliable service.

- Sorry for not special notice in advance if there would be changes on parameters.

Warning

- Unplug the tools before opening it.

- Incorrect use of hot-air blowers can cause fire and explosion hazardous especially near combustible materials and explosive gases

- Do not touch heater tube and nozzle when they are hot. They may cause burns. Do not point hot air flow in the direction of people or animals.

Tips:

1. This machine is welded with steel pressure roller to suite the hot air welding.

2. Any customized demands, you can ask us directly. We have professional technicians team.

If you are interested in other earthwork products,Please send inquiry to BPM Team and we reply you within 3 mins.

Hot Searches