NaN / 0

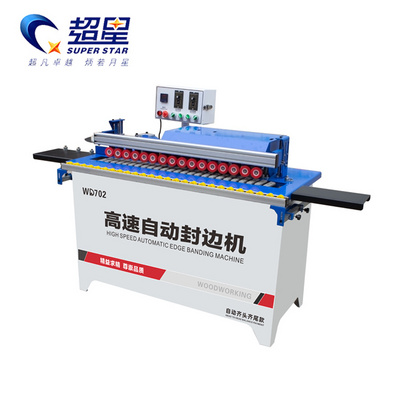

WF360A PVC Automatic Woodworking Edge Bander Banding Making Sealing Trimming Machinery for Furniture

Get Latest Price

US$ 5000

≥1 Sets

US$ 4800

≥11 Sets

US$ 4500

≥51 Sets

US$ 4300

≥101 Sets

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

WOODFUNG

Voltage:

220v/380v/415v

Dimension(L*W*H):

360x80x160cm

Product Details

Products Description

WF360A automatic edge banding machine Woodworking Machinery end trimming

This machine is specially designed and exclusive for foreign market by us,which is multifunction but favourable price.It is used

for MDF,wooden board and shaving board.It can complete the processes of feeding workpiece,feeding coiled material,edging,end

cutting,fine trimming,scraping and buffing.It can achieve the level as same as foreign machines and the price is favourable.It is

especially suitable for the factory producing board .

for MDF,wooden board and shaving board.It can complete the processes of feeding workpiece,feeding coiled material,edging,end

cutting,fine trimming,scraping and buffing.It can achieve the level as same as foreign machines and the price is favourable.It is

especially suitable for the factory producing board .

|

Model

|

WF60E

|

WF360A

|

WF360B

|

WF360C

|

WF360YC

|

WF360D

|

WF360F

|

||||||

|

Motor power

|

4KW

|

7.4KW

|

9.4KW

|

8.5KW

|

11KW

|

19KW

|

15KW

|

||||||

|

Panel width

|

≥60mm

|

≥60mm

|

≥60mm

|

≥60mm

|

≥60mm

|

≥60mm

|

≥60mm

|

||||||

|

Panel thickness

|

10~60mm

|

10~60mm

|

10~60mm

|

10~60mm

|

10~60mm

|

10~60mm

|

10~60mm

|

||||||

|

Edge band thickness

|

0.4~3.0mm

|

0.4~3.0mm

|

0.4~3.0mm

|

0.4~3.0mm

|

0.4~3.0mm

|

0.4~3.0mm

|

0.4~3.0mm

|

||||||

|

Edge band width

|

12~65mm

|

12~65mm

|

12~65mm

|

12~65mm

|

12~65mm

|

12~65mm

|

12~65mm

|

||||||

|

Feed speed

|

0~13m/min

|

0~13m/min

|

0~13m/min

|

0~13m/min

|

0~13m/min

|

0~13m/min

|

0~13m/min

|

||||||

|

Working pressure

|

0.7Mpa

|

0.7Mpa

|

0.7Mpa

|

0.7Mpa

|

0.7Mpa

|

0.7Mpa

|

0.7Mpa

|

||||||

|

size(LxWxH)

cm |

274*85

*148 |

370*93

*160 |

450*93

*160 |

418*93

*160 |

500*93

*160 |

590*93

*160 |

610*93

*160 |

||||||

|

WF60E

|

gluing,trimming,scrapping and buffing,also with manual end cutting

|

|

|

|

|

|

|

||||||

|

WF360A

|

gluing,end cutting,fine trimming,scrapping and buffing

|

|

|

|

|

|

|

||||||

|

WF360B

|

gluing,end cutting,rough trimming,fine trimming,scrapping and buffing

|

|

|

|

|

|

|

||||||

|

WF360C

|

gluing,end cutting,fine trimming,scrapping,vertical grooving,horizontal grooving and buffing

|

|

|

|

|

|

|

||||||

|

WF360YC

|

pre-milling,gluing,end cutting,rough trimming,fine trimming,scrapping and buffing

|

|

|

|

|

|

|

||||||

|

WF360F

|

pre-milling,gluing,end cutting,fine trimming,corner rounding,scrapping, and buffing

|

|

|

|

|

|

|

||||||

|

WF360D

|

gluing,end cutting,rough trimming,fine trimming,corner rounding,scrapping and buffing

|

|

|

|

|

|

|

||||||

Details Images

Edge banders

SOFT VANEER,PVC,ACRYLIC,PMMA,ABS EDGE BANDERS

Wood Panels

PAINTFREE,LAMINATE,PRATICAL,MDF,SOLID PANELS

Applications

cabinet,funiture,chairs,windowns,desk,etc.

DELTA Touch Screen Operation Panel

Taiwan Delta PLC microcomputer control system adopts touch screen intelligent control, which is convenient, quick and easy to use

ELECTRONIC SYSTEM

Pure copper motor, strong power, long service life, high-power motor improves work efficiency while ensuring safety

Gluing part

The glue pot is heated and glued, and the glue is coated with an imported technology structure to make the sheet and the edge

banding evenly glued.

The edge band and the sheet are pressed tightly through the pressing wheel, and the adhesion is firm.

banding evenly glued.

The edge band and the sheet are pressed tightly through the pressing wheel, and the adhesion is firm.

End Trimming

The front and rear aligning head is composed of the front aligning head and the rear aligning head. It moves through a linear CSK

guide rail.

It adopts the structure of automatic tracking and high-frequency high-speed motor to make the cutting smooth

guide rail.

It adopts the structure of automatic tracking and high-frequency high-speed motor to make the cutting smooth

Fine Trimming

The finishing knife is R2, leaving 5~6 wire allowance for scraping and trimming the arc with R2 trimming knife

Scrapping

It is used to eliminate the secondary wave marks caused by the cutting process of trimming non-linear motion, and make the upper

and lower parts of the board more smooth and tidy. At the same time, the scraping can also adjust the size of the arc to make the

edge banding effect better. .

and lower parts of the board more smooth and tidy. At the same time, the scraping can also adjust the size of the arc to make the

edge banding effect better. .

Polishing

Use a plate polishing wheel to clean the processed plate, remove excess glue, and make the edge-sealing end surface smoother

Finished working

Recommend Products

FAQ

Q1: What is the warranty for the machine?

For our woodworking machine, we have 18months warranty.

Q2:Can I choose the Plug?

Yes,we have 220V/440V/380V for your choice,and 1phase,3phase,50hz and 60hz

Q3.What is your lead time after i pay?

Normally,we have stock for the machine,only customized for voltage ,about 7days or 15days.

Q4:How long will i get the machine after i pay?

The machine will deliver by sea to your port.about 20~55days arrival.

Q5:Is it OK to print my logo on the product?

Yes.Please inform us formally before our production and confirm the design firstly for the mass production.

Q6:It is my first time to purchase goods from china,how do i do?

Do not worry,Aucox/Woodfung has 10years export experience to all over the world,

also has professional sales team,we also have agent in Russia,Algeria,Pakistan,Peru,Vietnam,etc.

Q7:How to pack the machine?

we use wooden box to packge the machine to protect them to be safe

Q8.I do not know chinese,will the operation panel in english or spanish or other?

Yes,all our machine are with Chinese and English,If you want only English or Spanish or other,

we also can customize to you,but lead time will be a little longer.

For our woodworking machine, we have 18months warranty.

Q2:Can I choose the Plug?

Yes,we have 220V/440V/380V for your choice,and 1phase,3phase,50hz and 60hz

Q3.What is your lead time after i pay?

Normally,we have stock for the machine,only customized for voltage ,about 7days or 15days.

Q4:How long will i get the machine after i pay?

The machine will deliver by sea to your port.about 20~55days arrival.

Q5:Is it OK to print my logo on the product?

Yes.Please inform us formally before our production and confirm the design firstly for the mass production.

Q6:It is my first time to purchase goods from china,how do i do?

Do not worry,Aucox/Woodfung has 10years export experience to all over the world,

also has professional sales team,we also have agent in Russia,Algeria,Pakistan,Peru,Vietnam,etc.

Q7:How to pack the machine?

we use wooden box to packge the machine to protect them to be safe

Q8.I do not know chinese,will the operation panel in english or spanish or other?

Yes,all our machine are with Chinese and English,If you want only English or Spanish or other,

we also can customize to you,but lead time will be a little longer.

Warranty

1. AUCOX Provide 15 months warranty for all customers.

2. During warranty, we provide free normal spare parts once machine has probem.

3. AUCOX will solve customer's machine problem within 24 hours from the time problem raised.

4. AUCOX has enough spare parts for machines.

5. When machine out of warranty, AUCOX still provide free technical support and spare parts charged to customers.

ATTENTION:all machines in the website is always improving,if there is a little changed,no care.it is not influence the

usage,better quality for always improvement.

2. During warranty, we provide free normal spare parts once machine has probem.

3. AUCOX will solve customer's machine problem within 24 hours from the time problem raised.

4. AUCOX has enough spare parts for machines.

5. When machine out of warranty, AUCOX still provide free technical support and spare parts charged to customers.

ATTENTION:all machines in the website is always improving,if there is a little changed,no care.it is not influence the

usage,better quality for always improvement.

Why Choose Us

Hot Searches