NaN / 0

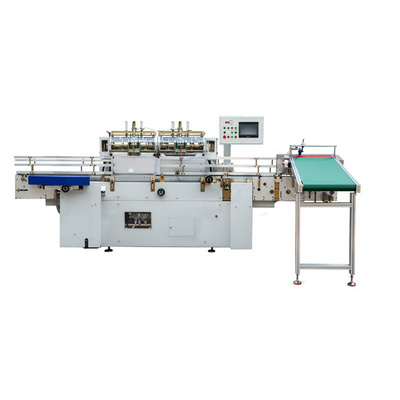

HXCP HX6000 Automatic Bookblock Maker Pressing Gluing and Hot Cold Drying Machine for Book Paperback Making Machine Electricity

Get Latest Price

US$ 260000

≥1 Pieces

Quick Details

Type:

Binding Machine

Production Capacity:

70pcs/min

Max. workable width:

2-80mm

Place of Origin:

Guangdong, China

Product Details

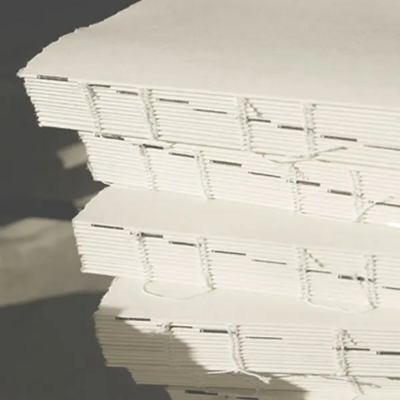

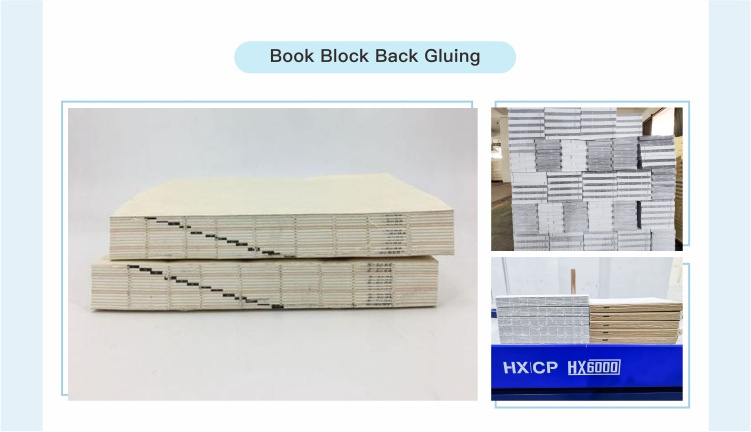

Including Pre-Pressing Lining Gluing Drying And Cooling Post Pressing Stations

1. Automatic book entry (saving manpower/increasing productivity)

2. NORDSON spray side glue (precision / high efficiency / neat machine)

3. SIEMENS Intelligent Electronic Control System

4. Double lining (thickness detection / height and low lining adjustment / thread suction head function / thread prevention head pasted on backing paper)

5. FESTO intelligent control injection system (the book spacing is accurate to 20mm/saving materials)

6. Book thickness detection

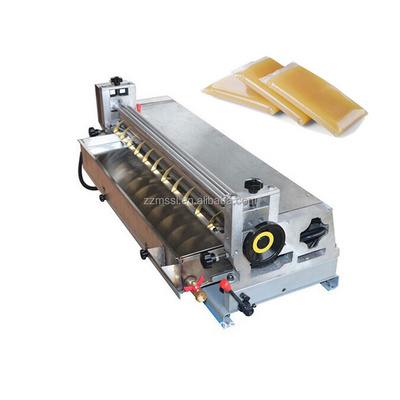

7. Glue (cold and hot glue/water cooling cycle device/temperature adjustable)

8. U-turn prevention marking device

9. Two-channel drying

10. Dual channel back pressure

11. Internet of things docking ERP/MCS online intelligent monitoring system

12. Imported customized gear box, precise transmission, high efficiency and long life

13. German original IWIS brand chain, precise transmission, stretch resistance, long life, avoid misalignment.

14. The integrated steel structure is welded, and the water-cooled circulation system ensures stable structure and long life.

15. The track uses German Mayford polymer composite wear-resistant nylon material and imported wear-resistant Cr steel material (KOLBUS) to improve stability

| Overall Size | 4.9x1.5m |

| Weight | 1000kg |

| Voltage | 380V |

| Power | 6KW |

| Air | 1.5L/min @6bar |

| Max. book size | 290*210mm |

| Min. book size | 140*80mm |

| Book block thickness | 8-45mm |

| Speed | 45 books / min |

Hot Searches