NaN / 0

Non Contact Measure Fuel Oil Tank Level Gauge Radar Level Sensor

Get Latest Price

US$ 50

≥1 Sets

Quick Details

Grade:

Industrial

Warranty:

1 Year

Place of Origin:

Henan, China

Brand Name:

WINDBELL

Product Details

Product Description

Windbell gas station tank gauge system mainly includes of SP series magnetostrictive probe and SS series console . Help managers to know the fuel level, water level and temperature in the underground diesel storage tank of the gas station anytime, anywhere.

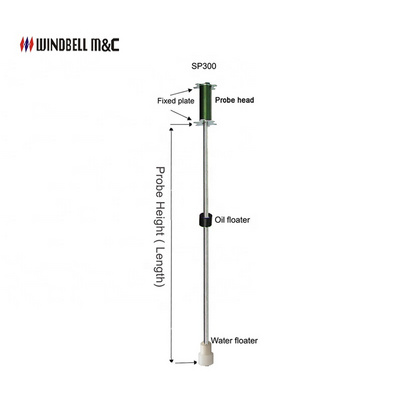

SP300 Magnetostrictive radar level sensor is mainly composed of probe head, temperature sensors, protection steel pipe, magnetostrictive waveguide wire and floaters with magnet inside. Insert probe into underground tank, floaters float on the liquid surface, and slides up and down on rod according to the changes of liquid level. Processing measured data of product level, water level, density values (option), and average temperature of five-points, then transmit these data to smart console by di gital communication port.

Advantages

Magnetostrictive Radar Level Sensor SP300

- ±0.5mm accuracy.

- RS485 communication protocol.

- 3-in-1 measurement, detect fuel height, fuel temperature and water height at the same time.

- 4 wires cable.

- IP68 protection grade.

- Intrinsically safe grade.

- ATEX, EAC, CQST, SIL approved.

- Length customized production.

- Applied in Gasoline, Kerosene, Diesel, Ethanol gasoline, Methanol gasoline, Approved light oil.

Parameters

| Magnetostrictive Radar Level Sensor SP300 | |

| Power supply | DC12V |

| Precision | ±0.5mm |

| Repeatability | ±0.1mm |

| Resolution of product level | 0.0069mm |

| Resolution of temperature | 0.0078ºC |

| Resolution of water level | 0.0069mm |

| Temperature range | -40 to 85ºC(-40 to 185ºF) |

| Points of temperature measured | 5 |

| Maximum communication distance | 1200m |

| Communication | RS485 |

| Intrinsic safety parameter |

Power port: Ui = 15V DC, Ii= 400mA, Pi = 1.5W, Ci =

3.63

μF, Li = 0mH;

Signal port: Ui = 7.14V DC, Ii= 147mA, Pi = 260mW, Ci = 32.6 μF, Li = 0mH; |

| Associated apparatus | WB-GSB03 safety barrier |

| Explosion proof grade | Ex ia IIA T4 Ga, Ex II 1G Ex ia IIA T4 Ga |

| Protection grade | IP6 8 |

| Applicable medium | Gasoline, kerosene, diesel, Ethanol gasoline, Methanol gasoline, Approved light oil |

| Definition of wires | Blue - Power +, Brown - RS485A , White - RS485B, Black - Power - |

| Communication address | 6 digits, see the"Manufacturing code"or S/N code on probe nameplate, this is also Probe ID in commun i cation with console and FMS |

| Dimension (L*W*H) | 243*12*12cm,5kg |

Related products

Packing information

FAQ

How the magnetostrictive probe working in the Automatic Tank gauge system?

How to select suitable probe for the tanks?

Hot Searches