NaN / 0

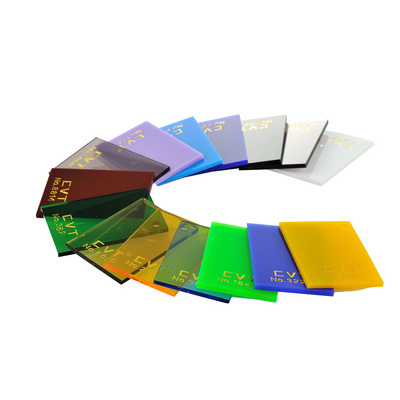

Solid Black Frosted Acrylic Sheet Matted Cast Acrylic Sheet Shining Glitter Acrylic Pearl Marble Mirror For Laser Cut

Get Latest Price

US$ 1.9

≥200 Kilograms

Quick Details

Processing Service:

Cutting, Moulding

Place of Origin:

Zhejiang, China

Brand Name:

ZhanYu

Model Number:

ZY

Product Details

|

Material

|

100% virgin MMA made from LUCITE/MITSUBISHI

|

|

|

|

|

|||||

|

Thickness

|

1.5-60mm

|

|

|

|

|

|||||

|

Color clear

|

White,opal,black,red,green,blue,yellow,etc.custom colors

|

|

|

|

|

|||||

|

Standard size

|

1000*2000,1220*1830,1220*2440,1830*2440,1220*3050*1525*2440,2050*3050mm

|

|

|

|

|

|||||

|

Certificate

|

CE,SGS,ISO9001:2015,ISO14001:2015,GRS

|

|

|

|

|

|||||

|

Equipment

|

Production lines are imported from German and Taiwan

|

|

|

|

|

|||||

|

MOQ

|

2tons,can be mixed with colors/sizes/thickness

|

|

|

|

|

|||||

|

Delivery

|

3-20days

|

|

|

|

|

|||||

|

Our Popular Sizes

|

|

|

|

|

|

|||||

|

With Edge(mm)

|

1050*2050

|

1270*1880

|

1270*2490

|

1880*2490

|

2100*3100

|

|||||

|

Without edge(mm)

|

1020*2020

|

1220*1830

|

1220*2440

|

1830*2440

|

2050*3050

|

|||||

|

Note:Please contact us for more sizes and cutting service are available

|

|

|

|

|

|

|||||

|

Thickness

:1.5-60mm

|

|

|

|

|

|

|||||

|

Physical Properties

|

|

|

|

Specific Gravity

|

1.19-1.20

|

|

|

Rockwell Hardness

|

M-100

|

|

|

Shear Strength

|

630kg/cm2

|

|

|

Tensile Strength

|

760kg/cm2

|

|

|

Yield Strength

|

1260kg/cm2

|

|

|

Light Transmittance

|

93%

|

|

|

Rupture Strength

|

1050kg/cm2

|

|

|

Refractive Index

|

1.49

|

|

|

Heat Distortion Temperature

|

100℃

|

|

|

Thermal Forming Temperature

|

140℃-180℃

|

|

|

Coefficient of linear Thermal Expansion

|

6*10-5cm/cm/℃

|

|

|

Dielectric Strength

|

20kv/mm

|

|

|

Water(24HRS)Absorption

|

0.30%

|

|

FAQ

1.Q:Are you a producer or trading company?

A: We are a professional manufacturer with 40 years experience in this field.Our factory is located in Longyou, Zhejiang province, China.

2.Q: How can i get the sample?

A: Small samples available are free, just freight collect.

3.Q: How long can I expect to get the sample?

A: We can prepare samples within 3 days. Usually it takes about 5-7 days for the delivery.

4.Q: Can we have our Logo or company name to be printed on your package?

A: Sure. Your Logo can be putted on the package by printing or sticker.

5.Q: What is your lead time for mass production?

A: Normally 10-20 days, depends on the size, quantity and season.

6.Q: How do you pack it?

A: Each sheet covered by PE film, several sheets wrapped by craft paper, and then 1.5 tons

packaged in a pallet.

7.Q: Why use CAST Acrylic verses EXTRUDED Acrylic ?

1. Continuous Service Temp: 180 F (Cast) vs. 160 F (Extruded)

2. Formability Temp: 340 F to 380 F (Cast) vs 290 F to 320 F (Extruded)

3. Cast acrylic has a higher molecular weight, therefore it will cut, drill and rout cleaner.

As you machine cast acrylic, the shavings will flake off whereas the extruded acrylic

shavings can gum up on the tool.

4. Cast acrylic also offers better glue-joint effectiveness and performs better in laser cutting.

8.Q: why you choose Zhanyu Cast Acrylic Sheet ?

A: Material we use is 100% virgin Lucite Material imported from UK. The models are from Pilkington. And we have four professional production lines to shortage the date of delivery.Most of all, we promise if there is any quality problems of our sheets, you can send the sheets back and we will send you the good sheets for free.

Hot Searches