NaN / 0

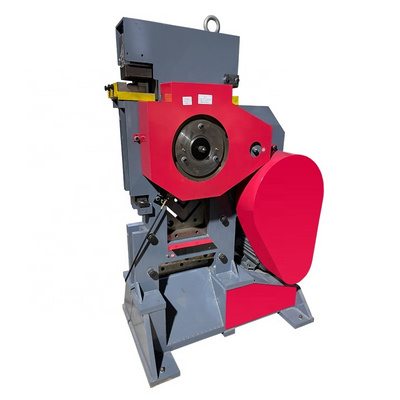

55Ton double Steel Plate Hole Punching die and tools Hydraulic Ironworker Machine

Get Latest Price

US$ 4700

≥1 Sets

Quick Details

Nominal Force (kN):

550

Place of Origin:

Jiangsu, China

Brand Name:

Super

Voltage:

380v 50hz 3ph

Product Details

Product Description

Hydraulic Iron Worker Product Application

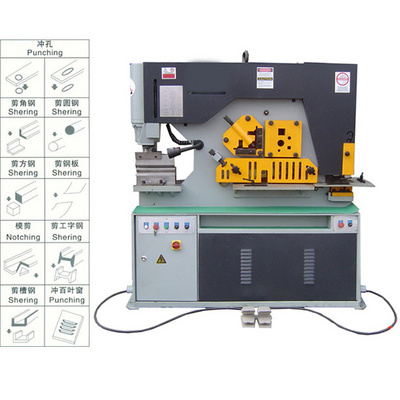

They adopt hydraulic driving system and they are the latest iron workers in our country, various metal plate, square bar, Round bar, angle, channel and joist can be cut, punched and notched on the machine. It is also equipped with a stop device for cutting.

1) 2 separate hydraulic piston and foot pedal to allow 2 operator to work at the same time2) More productivity with adjustable piston stroke distance

3) Central lubrication system

4) Electrical back gauge

5) Working light

6) Five individual workstation on the machine:

a) Ø26 mm punch and die and standard punching tools

b) Steel solid round and square bar cutting blade set

c) Angle cutting blade set

d) Sheet metal cutting shear

e) U-Notching blade set

|

SPECIFICATIONS FOR HYDRAULIC IRON WORKER

|

|

|

|

|

|

|||||

|

Specification

|

Model

|

Q35Y-12

|

Q35Y-15

|

Q35Y-16

|

Q35Y-20

|

|||||

|

Process Capacity

|

|

40T

|

55T

|

60T

|

90T

|

|||||

|

Punching

|

Dia.(punch)*Thickness(mm)

|

22*12

|

24*15

|

25*16

|

30*20

|

|||||

|

|

Ram Stroke(mm)

|

60

|

60

|

80

|

80

|

|||||

|

|

No. of stroke(times/min)

|

8

|

8

|

8

|

8

|

|||||

|

Cutting

|

Max.thickness of plate (mm)

|

12*250

|

15*300

|

16*250

|

20*330

|

|||||

|

|

Max. width of plate (mm)

|

/

|

/

|

8*400

|

10*480

|

|||||

|

Angle Shearing

|

90

0

shearing (mm)

|

100*10

|

120*12

|

125*12

|

140*12

|

|||||

|

|

45

0

shearing (mm)

|

70*6

|

60*6

|

50*5

|

50*5

|

|||||

|

Notching

|

Thickness (mm)

|

12

|

15

|

16

|

20

|

|||||

|

|

Width (mm)

|

22

|

24

|

25

|

30

|

|||||

|

|

Depth (mm)

|

200

|

200

|

300

|

350

|

|||||

|

SPECIFICATIONS FOR HYDRAULIC IRON WORKER

|

|

|

|

|

||||

|

Specification

|

Model

|

Q35Y-25

|

Q35Y-30

|

Q35Y-40

|

||||

|

Process Capacity

|

|

110T

|

140T

|

200T

|

||||

|

Punching

|

Dia.(punch)*Thickness(mm)

|

35*25

|

38*26

|

41*35

|

||||

|

|

Ram Stroke(mm)

|

80

|

80

|

100

|

||||

|

|

No. of stroke(times/min)

|

6

|

6

|

8~25

|

||||

|

|

Max.thickness of plate (mm)

|

25*330

|

30*355

|

35*400

|

||||

|

|

Max. width of plate (mm)

|

16*600

|

20*600

|

25*700

|

||||

|

|

90

0

shearing (mm)

|

160*14

|

180*16

|

200*18

|

||||

|

|

45

0

shearing (mm)

|

60*6

|

60*6

|

80*10

|

||||

|

Notching

|

Thickness (mm)

|

25

|

26

|

35

|

||||

|

|

Width (mm)

|

35

|

38

|

41

|

||||

|

|

Depth (mm)

|

400

|

600

|

60

|

||||

Detailed Images

Punching Station

Solid Stock , Flat Bar and Angle Shearing Stations.

Rectangle Notching Station

Mould Tooling and Samples.

Packing & Delivery

Our Customers

Our Company

Contact Us

Hot Searches