NaN / 0

Factory Price 1L 5L Edible Cooking Oil Bottle Filling Machine Peanut Beans Oil Filling Machine Sunflower Oil Filling Machine

Get Latest Price

US$ 3800

≥1 Sets

Quick Details

Machinery Capacity:

4000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

Packaging Material:

Plastic, Glass

Filling Material:

Beer, Milk, Water, Oil, Juice, Powder

Filling Accuracy:

±1%

Product Details

Machine Introduction

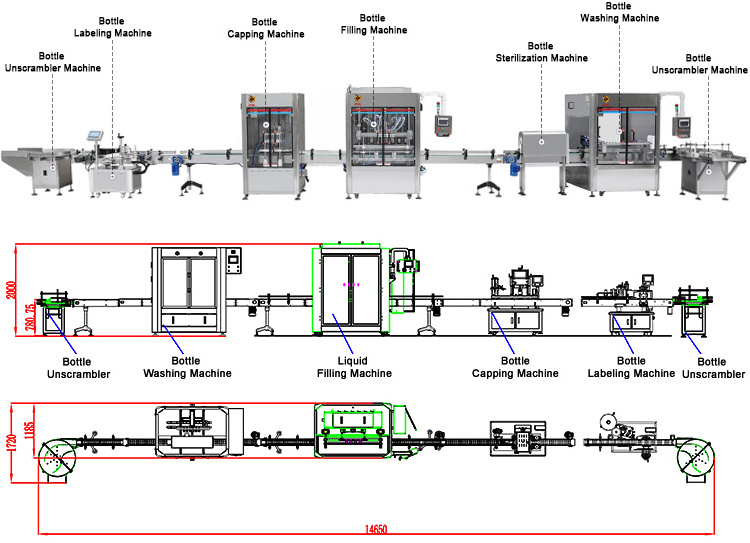

JKMF Automatic liquid filling line is a type of production line used to fill liquid products into containers automatically. This production line is widely used in various industries such as food and beverage, cosmetics, and chemical manufacturing.

Liquid filling lines provide numerous benefits, including increased productivity and accuracy, enhanced safety, reduced material waste, versatility, and cost-effectiveness.

JKMF Filling Machine with advanced automation technology, automatic liquid filling lines can greatly improve the efficiency and productivity of liquid filling processes while ensuring high accuracy and consistency of product filling.

Liquid filling lines are a crucial component in numerous industries, enabling the automated and accurate filling of liquid products into containers of varying shapes and sizes.

Such as

vials, ampoules, bottles, jars, tubes and other containers.

Food and beverage industry: J

uices, honey, sauces, oils, and beverages.

Cosmetics industry: Shampoos, lotions, creams, and serums.

Chemical industry: S

olvents, acids, and detergents.

Automotive industry: Lubricants, coolants, and brake fluids.

Machine Details

Automatic liquid filling lines typically include

filling machines, capping machines, labeling machines, and conveyor systems

, which work together to efficiently and accurately fill containers with liquid products.

|

Liquid Filling Line

|

|

|

|

Number of Filling Heads

|

2 / 4 / 6 / 8 / 10 / 12 / 16 / 20 (Support customization)

|

|

|

Filling Range

|

10ml ~ 1000ml (Support customization: Max.50L)

|

|

|

Filling Speed

|

200 ~ 4800 Bottles/hour(According to packaging needs)

|

|

|

Machine Power

|

220V, 4.2KW, 0.6~0.8 MPa

|

|

|

Program Controller

|

Siemens, Germany

|

|

|

Touch Screen

|

Siemens, Germany

|

|

|

pneumatic components

|

Taiwan AIRTAC / Japan SMC

|

|

|

photoelectric Sensor

|

Germany LEUZE / Japan Panasonic

|

|

Bottle Washing Machine

Machines typically use a combination of water, cleaning agents, and disinfectants to thoroughly clean the bottles and remove any debris, bacteria, or other contaminants that could affect the quality and safety of the product.

Bottle Drying and Sterilizing Machine

This machine is usually used together with a bottle washing machine.

After the bottle is cleaned, the machine dries the bottle and can be equipped with an ultraviolet sterilizing system to ensure clean and hygienic production.

Automatic Filling Machine

The pneumatic filling nozzle can ensure filling paste faster,it is with anti-dripping design which ensure the machine and production cleanliness.

The machine is equipped with high quality electric eye,can detect passing by container accurately and realize the automated work,reduce the production error and improve working eficiency.

Bottle Capping Machine

The PLC control system is intelligently controlled and easy to operate. The adjustable cap chute is suitable for caps of different sizes, and the capping speed is up to 160 BPM. If the cover is missing, it will automatically shut down and give an alarm to reduce waste.

Bottle Labeling Machine

Automatic labeling machine for the whole high-garde stainless stell and high-garde aluminum alloy, labeling head using high-speed servo motor to ensure the accuracy and speed of labeling, PLC with man-machine interface contral, simple operation clear.

Why Choose Us

1. Strength Factory

Foshan Jike Bee Automation Equipment Co., Ltd. is a leading manufacturer of automatic packaging equipment, dedicated to product innovation, direct sales, and exceptional after-sales service. Our equipment for granules, powders, liquids, and sauces is at the forefront of the industry, and we specialize in customizing automatic packaging lines for a wide range of products.

Our equipment is widely used in food, hardware, cosmetics, fruits and vegetables, and other industries. We take pride in our product technical certification and patent ownership, ensuring that our customers receive high-quality equipment that they can trust.

At Foshan Jike Bee Automation Equipment Co., Ltd., we strive to be a production-oriented enterprise, continuously innovating to provide our customers with the best solutions. With our commitment to quality and excellence, we are confident that our automatic packaging equipment will meet and exceed your expectations.

2.

High Quality Machine

Our VFFS packing machines are known for their superior quality and reliability. We have obtained numerous patent certificates and certifications, including EU CE and ROHS, demonstrating our commitment to producing high-quality equipment.

Our team of experienced professionals continually strives to innovate and improve our equipment to meet and exceed industry standards.

3.

Excellent After-sales Service

At Foshan Jike Bee Automation Equipment Co., Ltd., we're committed to providing not only high-quality VFFS packing machines but also professional after-sales services.

Our team offers online technical support, on-site installation training, and more to ensure that our customers can use our equipment to its fullest potential.

4.

Customer Praise

At our company, we understand that providing customers with top-quality equipment is just the beginning. That's why we also provide expert industry advice and unparalleled after-sales service, all of which has resulted in glowing reviews from our satisfied customers.

FAQ

Q1:Do you have manual or operation video for us to know more about the machine?

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q2:How can I trust you for the first time business ?

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3:Is engineer available to serve oversea?

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4:How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Q5:Will you provides the door to door service?

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q2:How can I trust you for the first time business ?

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3:Is engineer available to serve oversea?

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4:How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Q5:Will you provides the door to door service?

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

Hot Searches