NaN / 0

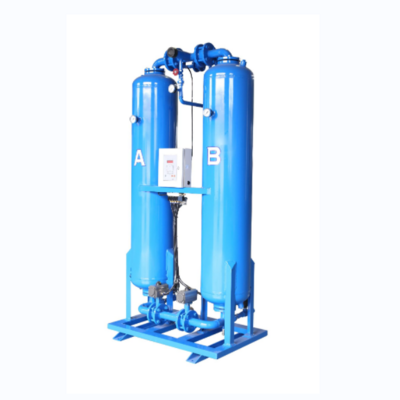

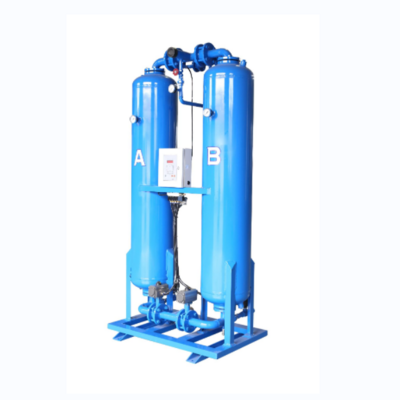

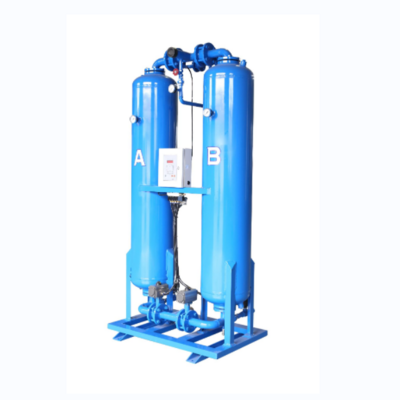

Heatless regeneration desiccant air dryer for air compressor

Get Latest Price

US$ 700

≥1 Pieces

Quick Details

Model NO:

SDXJ

Transport Package:

Carton or wooden cases

Trademark:

Shanli

Origin:

China

Product Details

Heatless regeneration desiccant compressed air dryer

Applicable working conditions

Max air inlet temperature:45℃

Working pressure range:0.5-1.0Mpa

Pressure dew point:-20℃~-40℃

Pressure loss:≤ 3% of design working pressure

Oil content of air inlet :≤0.1PPm

Control mode:Micro computer/PLC controller

Power:AC220V/50HZ,

Working cycle: T=10(min)

Product features

10 minutes standard cycle;

Working pressure dew point -20℃~-40℃;

High-quality switching valve, stable and reliable, can ensure the integrity of the work process and prolong the working life of components;

Choosing Special adsorbents with highly hygroscopic , uniform shape and size, high strength, low output dew point, less dust generated, and long service life;

The amount of regeneration air can be adjusted according to the operating load requirements of the equipment to achieve energy saving effect

Reasonable heater design, good dehumidification and regeneration effect, low air consumption, high heating efficiency, and minimized energy consumption;

Programmable microcomputer controller, that adsorption and regeneration time can be adjusted to achieve your satisfactory dew point value;

Table 1:Working pressure correction factor CFP

Air Inlet pressure | Mpa | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 |

CFP | 0.75 | 0.88 | 1 | 1.13 | 1.25 | 1.38 |

Table 2: Air inlet temperature correction factor CFT

Air inlet temperature | ℃ | 20 | 25 | 30 | 35 | 38 | 45 |

CFT | 1.2 | 1.1 | 1 | 1 | 1 | 0.75 |

Selection process

The pressure loss of the pre-filter in the system must be considered

when choosing the correction factor CFP of inlet pressure of dryer.

Select the air inlet temperature correction factor CFT.

Selection calculation formula: selection treatment capacity = actual treatment capacity÷(CFPXCFT)

Product specifications

Model Item | Air capacity | Desiccant Weight | Air Connection pipe diameter | N.W | Long(mm) | Width (mm) | height (mm) |

SDXW-1PB | 1.2 | 40 | G1" | 165 | 810 | 500 | 1275 |

SDXW-2PB | 2.5 | 45 | G1" | 235 | 810 | 500 | 1325 |

SDXW-3PB | 3.6 | 60 | G1" | 355 | 810 | 500 | 1675 |

SDXW-4.5PB | 5.0 | 100 | G1-1/2" | 385 | 1040 | 600 | 1793 |

SDXW-6PB | 6.8 | 120 | G1-1/2" | 480 | 1040 | 600 | 2143 |

SDXW-8PB | 8.5 | 180 | G2" | 600 | 1200 | 600 | 2246 |

SDXW-10PB | 10.9 | 200 | G2" | 755 | 1200 | 600 | 2346 |

SDXW-12PB | 12.8 | 200 | G2" | 755 | 1200 | 600 | 2346 |

SDXW-15PB | 16 | 310 | DN65 | 775 | 1310 | 769 | 2329 |

SDXW-20PB | 22 | 492 | DN65 | 1030 | 1410 | 769 | 2390 |

SDXW-25PB | 26.8 | 578 | DN80 | 1200 | 1510 | 818 | 2774 |

SDXW-30PB | 32 | 600 | DN80 | 1220 | 1565 | 815 | 2501 |

SDXW-40PB | 43.5 | 856 | DN100 | 1640 | 1854 | 963 | 2687 |

SDXW-50PB | 53 | 1002 | DN100 | 1650 | 1900 | 978 | 2707 |

SDXW-60PB | 67 | 1334 | DN125 | 2390 | 2166 | 1100 | 2869 |

SDXW-80PB | 90 | 1608 | DN125 | 2900 | 2864 | 1059 | 2857 |

SDXW-100PB | 110 | 2000 | DN150 | 3800 | 3460 | 1230 | 3048 |

SDXW-120PB | 130 | 2435 | DN150 | 4330 | 3560 | 1305 | 3094 |

SDXW-150PB | 160 | 2926 | DN200 | 5270 | 3960 | 1450 | 3332 |

SDXW-200PB | 210 | 4070 | DN200 | 6920 | 4360 | 1605 | 3471 |

SDXW-250PB | 260 | 4710 | DN250 | detailed parameters contact to the factory | |||

SDXW-300PB | 310 | 6160 | DN250 | detailed parameters contact to the factory | |||

Hot Searches