NaN / 0

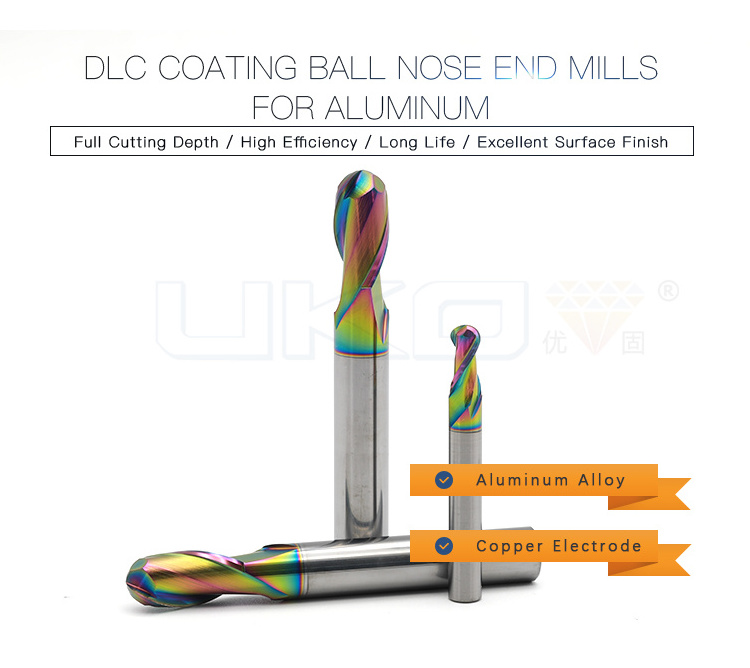

Aluminum Use CNC Tool DLC Coating Ball Nose Solid Carbide End Mill 2 Flute Milling Cutter

Get Latest Price

US$ 3.99

≥10 Pieces

Quick Details

Material:

Carbide

Coating:

DLC COATING

Warranty:

NO

Place of Origin:

Hunan, China

Product Details

Aluminum Use CNC Tool DLC Coating Ball Nose Solid Carbide End Mill 2 Flute Milling Cutter

Product Description

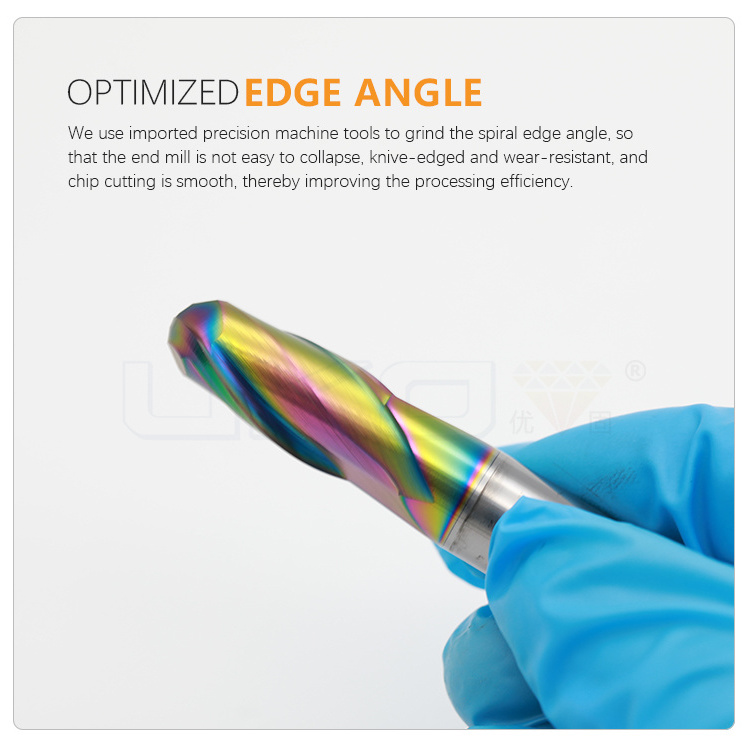

Raw Material: Use GU20 uniform material, good toughness. Widely used in the production and manufacture of integral tools such as

end mills, drills, etc.

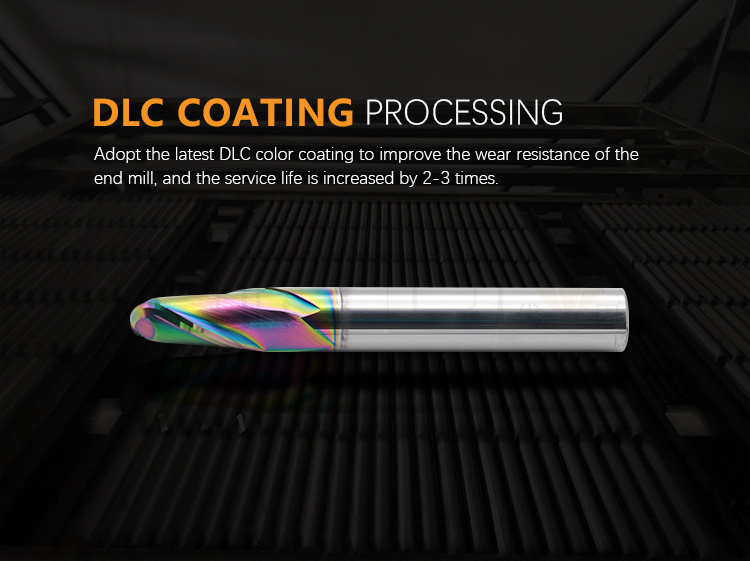

Coating: DLC(Diamond-like carbon) coating, thickness: 1-2μm.

With ultra-high hardness, low friction coefficient, high temperature resistance, good electrical insulation, chemilcal barrier,

high thermal conductivity and ultra-high anti-blocking performance.

end mills, drills, etc.

Coating: DLC(Diamond-like carbon) coating, thickness: 1-2μm.

With ultra-high hardness, low friction coefficient, high temperature resistance, good electrical insulation, chemilcal barrier,

high thermal conductivity and ultra-high anti-blocking performance.

|

Workpiece Material

|

|

|

|

|

|

|

||||||

|

Carbon Steel

|

Alloy Steel

|

Cast Iron

|

Aluminum Alloy

|

Copper Alloy

|

Stainless Steel

|

Hardened Steel

|

||||||

|

|

|

|

√

|

√

|

|

|

||||||

Our Advantages

Specification

Application

UKO supplies the latest DLC color coating end mills for aluminum copper. This is a special kind of milling cutter, which can provide predictable and long tool life for slotting and groove milling processing. It has good self-lubrication and surface hardness, and the mill wear resistance is significantly improved.

Tips of operation instructions

In order to get better cutting surface and extend tool life. Please be sure to use the handle with high precision, high rigidity

and good dynamic balance.

1. Before using the tool, please measure the tool deflection. When the tool deflection accuracy exceeds 0.01mm, please calibrate it before cutting.

2. The shorter the length of the tool overhanging chuck, the better. If the overhanging amount of the tool is too long, please adjust the speed, feed speed or cutting quantity by yourself.

3. In case of abnormal vibration or sound during cutting, please adjust the spindle speed and cutting quantity until the situation improves.

4. Spray or jet cooling is the best way to make the best effect of high alumina and titanium. Insoluble cutting fluids are

recommended for stainless steel, titanium or heat resistant alloys.

5. The cutting mode depends on the influence of working piece, machine and software.

Above data are for reference only.

Specific situation needs

detailed analysis

, if you have any questions, please consult us.

Related Products

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

About Us