NaN / 0

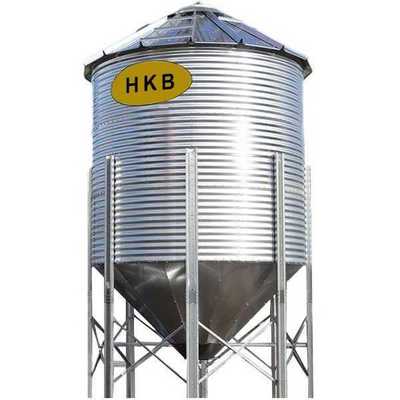

Small Grain Silos Capacity 10 Ton 20t 30t 40t 50t Steel Silos Cost

Get Latest Price

US$ 700

≥1 Sets

US$ 599

≥5 Sets

US$ 480

≥10 Sets

US$ 399

≥20 Sets

Quick Details

Applicable Industries:

Poultry Farm

Marketing Type:

Hot Product 2023

Core Components:

Galvanized Sheets

Place of Origin:

Shandong, China

Product Details

Products Description

The feed silo is mainly composed of silo body, silo cover, mounting ladder, and silo legs etc. All parts are produced in strict

accordance with drawing design by using advanced laser equipment and precision molds, and then undergo strict quality inspections to make each component more standard, more precise in size, and more convenient to install to ensure easy assembly and use.

accordance with drawing design by using advanced laser equipment and precision molds, and then undergo strict quality inspections to make each component more standard, more precise in size, and more convenient to install to ensure easy assembly and use.

|

Capacity

(MT)

|

Diameter

(m)

|

Height

(m)

|

Layer

|

Support Legs

|

Thickness of Legs

(mm)

|

Thickness of

silo body

(mm)

|

Galvanized

coating

Thickness

(g/m²)

|

Volume Capacity

(CBM)

|

|

3

|

2.2

|

3.4

|

1

|

4

|

2.5

|

1

|

275

|

5.6

|

|

5

|

2.5

|

4.4

|

1

|

4

|

2.5

|

1

|

275

|

7.6

|

|

10

|

2.75

|

5.4

|

2

|

6

|

2.5

|

1

|

275

|

15.8

|

|

15

|

2.75

|

6.3

|

3

|

6

|

2.5

|

1

|

275

|

21.6

|

|

18

|

3.0

|

6.3

|

3

|

6

|

2.5

|

1.2

|

275

|

25.5

|

|

20

|

3.26

|

6.6

|

3

|

8

|

2.5

|

1.2

|

275

|

29.8

|

|

25

|

3.67

|

6.6

|

3

|

8

|

3.0

|

1.2

|

275

|

38.5

|

|

30

|

3.67

|

7.5

|

4

|

8

|

3.0

|

1.2

|

275

|

48.1

|

Details Images

Application

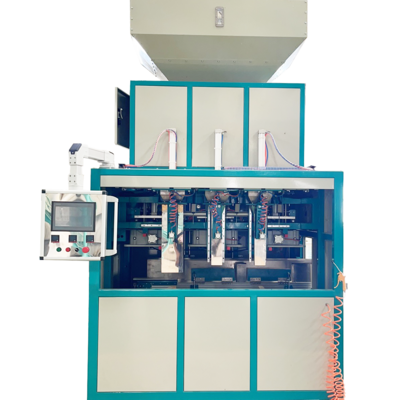

Product packaging

Hot Searches