NaN / 0

cooking oil filling production line edible olive vegetable oil making machine/cooking oil manufacturing

Get Latest Price

US$ 33000

≥1 Sets

US$ 32000

≥2 Sets

US$ 31000

≥3 Sets

Quick Details

Packaging Material:

Wood

Place of Origin:

Jiangsu, China

Function:

Linear filling

Keyword:

Oil packing machine

Product Details

Our company

Product Description

Product Application

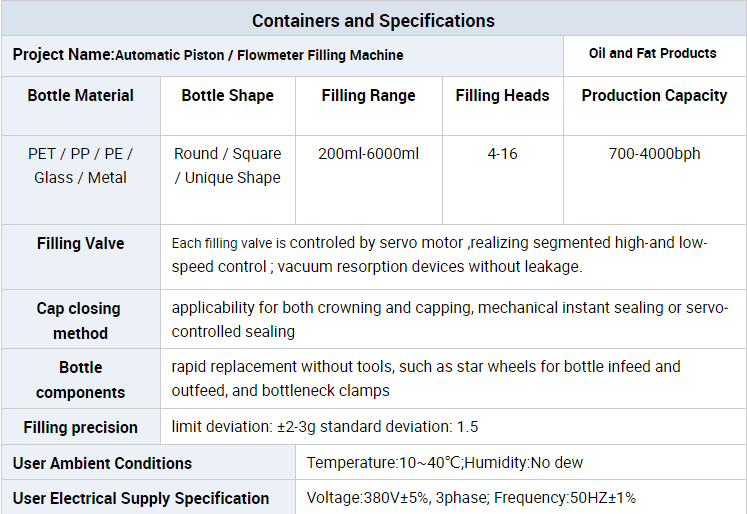

The machine is a new type of piston filler for large dose filling.It has the characteristics of stable run,beautiful

appearance,and easy operation.It is suitable for filling of water and paste materials,such as seed coating agent,suspension

concentrate,etc.

The machine is equipped with filling blocker to prevent leaking and dropping tread.It is an ideal kind of pacing equipment within

the food,medicine,chemicals,and pesticides industry,etc.

The piston cylinder driven by the servo motor,that makes a higher and much more sdouble ball-screw makes the filling operation

and accuracy perfectly table filling precision.

The part touching the material is made of good quality stainless steel.The part touching the material is made of good quality

stainless steel.The machine fully meets the GMP standard.

Detailed Images

Filling Heads

1.The adjustment in dosage is convenience and quick, the volume only need to be set on the touchscreen directly, considered that

the vegetable oil is different in density in the different temperature ,resulting in the volume setting different , we have added

an automatic temperature-compensated system.2.Filling accuracy: Instead of the traditional computing type of flowmeter-- through

pulse generator

3.Filling speed: instead of the traditional power delivery -- pressure artesian flow, adopting frequency converter to adjust the

speed of filling,the efficiency highly raised. The speed can be arbitrarily adjusted on panel.

4.The adjustment of filling accuracy, promoted by our company, the weight of filling can be set on the touchscreen.The equipment

carries on automatic conpensation system when error occurs.

5.Each filling head’s speed of machine can be set on touchscreen.

6.Conveyor belt be adjusted by frequency conversion

the vegetable oil is different in density in the different temperature ,resulting in the volume setting different , we have added

an automatic temperature-compensated system.2.Filling accuracy: Instead of the traditional computing type of flowmeter-- through

pulse generator

3.Filling speed: instead of the traditional power delivery -- pressure artesian flow, adopting frequency converter to adjust the

speed of filling,the efficiency highly raised. The speed can be arbitrarily adjusted on panel.

4.The adjustment of filling accuracy, promoted by our company, the weight of filling can be set on the touchscreen.The equipment

carries on automatic conpensation system when error occurs.

5.Each filling head’s speed of machine can be set on touchscreen.

6.Conveyor belt be adjusted by frequency conversion

Sealing Parts

1.Bottles conveyed in straight line, continual gland, highly effective; automatic sorting caps and falling caps

2.auto capping machine, rotation type conveying caps, no noisy, no shake.

3.The machine will stop automatically when some troubles occures, more reliable.

4.Suitable for all sizes of bottles

2.auto capping machine, rotation type conveying caps, no noisy, no shake.

3.The machine will stop automatically when some troubles occures, more reliable.

4.Suitable for all sizes of bottles

Our services

FAQ

Customer Photos

Hot Searches