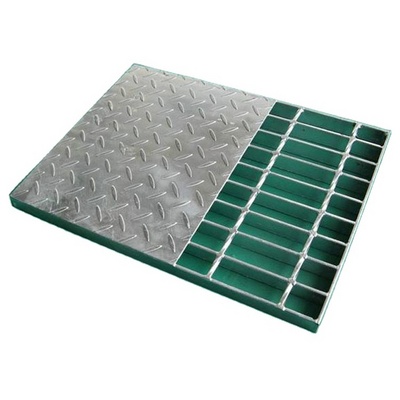

Steel bar grating with high strength and firm structure is made up of carbon steel, aluminum steel, or stainless steel. According

to the manufacturing methods, it can be divided into four types: welded, press-locked, swage-locked, and riveted gratings.

According to the surface shapes, it can be divided into smooth and serrated gratings. With various styles and sizes for choice,

steel gratings are widely used in everyday life, such as stair treads, walkways, platforms, floors, various covers, wheeled

equipment, security screens, heavy-duty constructions, and so on.