NaN / 0

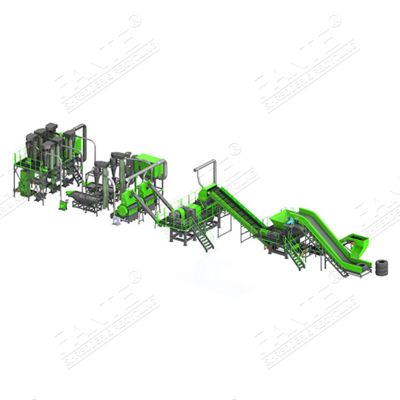

Waste Tyre Recycling Plant/Reclaimed Rubber Machine/Used Tire Recycling Machine

Get Latest Price

US$ 40000

≥1 Sets

US$ 38000

≥5 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

Yahua

Model Number:

XLB-D

Voltage:

Customer Request

Product Details

Waste Tyre Recycling Plant/Reclaimed Rubber Machine/Used Tire Recycling Machine

Product Description

The line is consisit with two parts, rubber crusher mill and auxiliary devices. This line mainly used for recycling waste tire( container steel wire and fiber wire) into rubber powder and also processing waste rubber products into powder. Main machine is rubber crusher mill, there have three models could meet customers' requiremets.

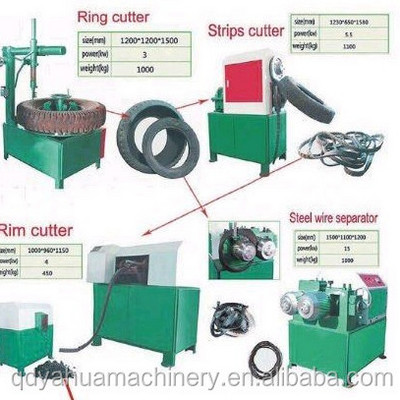

The auxiliary devices containe loop machine, ring cutter, strip cutter, block cutter, conveyor, vibrating device and magnetic separator.

For the request of market, most clients need the powder reach to 80-100 meshes. Then the line will attach fiber separator and refining mill machine.

Waste tire recycling machine use to make old& waste tire into powder and collect steel wire. The powder could produce reclaimed rubber.

Rubber crushing mill machine

The roll is made of chilled cast iron with vanadium and titanium alloys. The roll face is hard and anti-wear. Both the front roll and the back roll are plaim. The internal cavity of the roll is processed to make temperature well proportioned on the roll surface.

The machine is equipped with an overaload protection device to prevent the major components from being damaged due to

overloading.

The machine is also equipped with an emergency device. When an emergent accident happens, just draw the safety pull-rod, and the machine will stop immediately. It is safe and reliable.

The machine is applicable for breadking scrap rubber and raw rubber, also breaking radial steel tires and ordinary tires.

| model | XKP-400 | XKP-450 | XKP-560 |

| working diameter of front roll(mm) | 400 | 450 | 560 |

| working diameter of back roll(mm) | 400 | 450 | 510 |

| working length of rolls(mm) | 600 | 650 | 800 |

| linear speed ratio of rolls(m/min) | 18.65 | 24.5 | 25.16 |

| linear speed ratio | 1:1.27 | 1:1.27 | 1:1.28 |

| max gap(mm) | 10 | 10 | 15 |

| output(kg/h) | 200-400 | 400-600 | 2000 |

| overall dimension(mm) | 3850x1800x1550 | 4650x2000x1550 | 4750x2300x1750 |

ring cutter

| motor power | 5.5kw |

| speed of main screw | 46.8 r/min |

| max diameter of tire | 1200mm |

| dimension | 1100x900x1700mm |

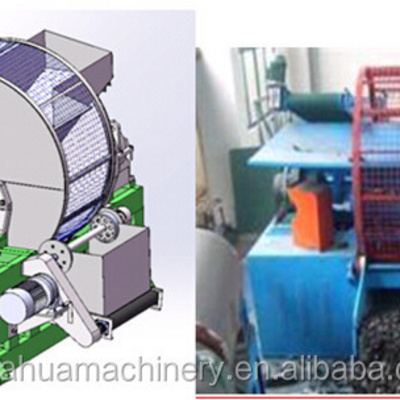

loop machine

| motor power | 15kw |

| front roller linear speed | 15.5m/min |

| ratio of speed | 1:1.1 |

| overall size(mm) | 1520x1150x1210 |

Strip cutter

| motor power | 5.5kw |

| dise diameter | 380mm |

| rotate speed | 18.4m/min |

| dimension | 1290x870x1550mm |

Block cutter

| motor power | 11kw |

| speed of main screw | 420r/min |

| out diameter of cutter | 200mm |

| dimension | 1130x830x1100mm |

Packaging & Shipping

Hot Searches