Name: GGD type electrical control cabinet

Brand: CHINT, SIEMENS, Schneider, Omron, etc.

Original: China, Germany, French, Japan, etc.

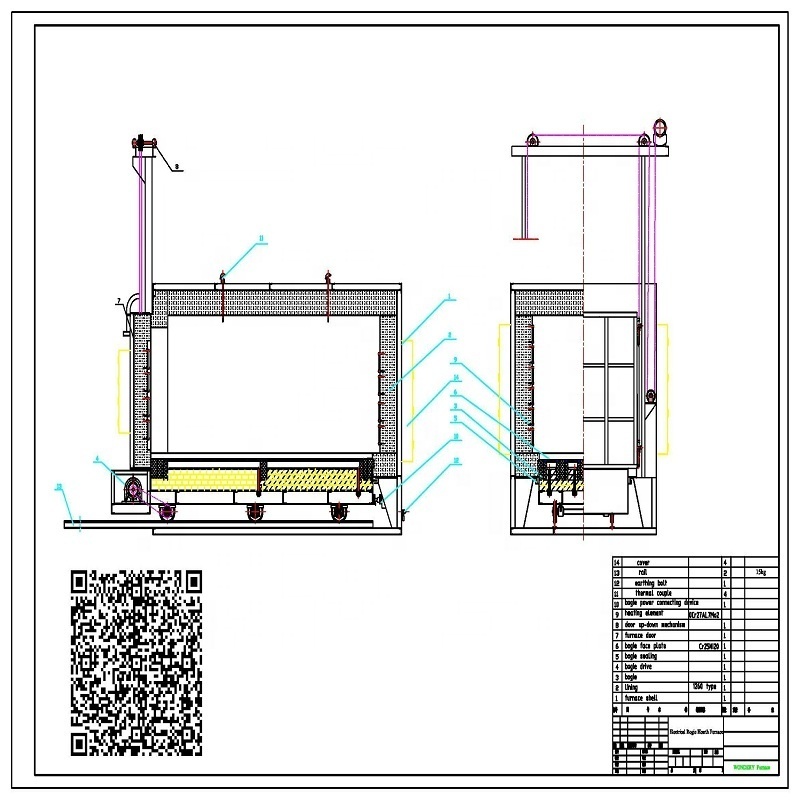

High Temperature Bogie Hearth Electric Resistance Heat Treatment Furnace is state standard energy saving cyclic furnace. It is a fiber structure saving 60% power consumption. It is among the first manufacturers to employ compound high aluminum porcelain nail group, trolley anti-explosion sealing bricks, automatic sealing trolley and furnace door, and integrated rail. This series furnace is applicable to the quenching, annealing and aging treatment of high chrome parts, high manganese cast parts, cast iron, rolls, steel balls, 45# steel parts and others.

|

SPECIFICATIONS FOR

High Temperature Bogie Hearth Electric Resistance Heat Treatment Furnace

|

|

|

|

|||

|

Temperature control

system

|

Rated Temperature

|

℃

|

1300

|

|||

|

|

common heating temperature

|

℃

|

400-1250

|

|||

|

|

Furnace body exterior temperature

|

℃

|

≤ 55 + room temperature

|

|||

|

|

Temperature control system precision

|

℃

|

≤±1

|

|||

|

|

Uniformity of furnace temperature

|

℃

|

≤±10

|

|||

|

|

Voltage

|

|

according to customer's

|

|||

|

|

Temperature Control Method

|

|

PID

|

|||

|

|

Components brand

|

|

Siemens, Schneider, CHINT(or other quality domestic or overseas brand)

|

|||

|

Mechanical system

|

door lifting mechansim

|

|

electric hoist

|

|||

|

|

bogie driving system

|

|

reducing motor

|

|||

|

|

door and bogie moving speed

|

m/min

|

6-8

|

|||

|

Refractory lining

|

hearth lining

|

|

aluminum silicate fiber

|

|||

|

|

bogie lining

|

|

refractory brick

|

|||

1) High Temperature Bogie Hearth Electric Resistance Heat Treatment Furnace has a shell of welded steel plates and sectional steel. The structure is of thick material.

2) The hearth wall lining is an all-fiber structure, saving about 60% of power consumption compared with the traditional brick hearth.

3) Heating components: high temperature resistance alloy wires and strips.

4) Low noise, energy-friendliness, and stable performance.

5) Advanced CAD design.

6) Years of experiences in heat treatment process.

Name: GGD type electrical control cabinet

Brand: CHINT, SIEMENS, Schneider, Omron, etc.

Original: China, Germany, French, Japan, etc.

Material:

0Cr25AL5

Brand: Beijing Shougang Co., Ltd.

Original: China

The heating elements could be of other international brands if required.

Name:

air and gas pipe system

Brand:

SINON burner, imported

Original:

Germany

|

Model

|

Hearth Size (mm)

L*W*H

|

Rated Power (kw)

|

Empty Furnace Rising Time (h)

|

Max Loading Capacity (kg)

|

|

RT2-30-9

|

950×500×450

|

30

|

2.5

|

500

|

|

RT2-45-9

|

1100×600×400

|

45

|

2.5

|

800

|

|

RT2-65-9

|

1200×600×450

|

65

|

2.5

|

1000

|

|

RT2-75-9

|

1500×750×600

|

75

|

2.5

|

1500

|

|

RT2-90-9

|

1800×900×600

|

90

|

2.5

|

2500

|

|

RT2-105-9

|

1800×900×650

|

105

|

2.5

|

3500

|

|

RT2-120-9

|

2000×900×700

|

120

|

2.5

|

4000

|

|

RT2-135-9

|

2000×1000×750

|

135

|

2.5

|

4200

|

|

RT2-150-9

|

2200×1000×800

|

150

|

2.5

|

5000

|

|

RT2-180-9

|

2200×1050×750

|

180

|

2.5

|

6000

|

|

RT2-200-9

|

2400×1200×800

|

200

|

2.5

|

6500

|

|

RT2-220-9

|

2500×1300×900

|

220

|

2.5

|

7000

|

|

RT2-240-9

|

2500×1400×900

|

240

|

2.5

|

8000

|

|

RT2-250-9

|

2800×1500×900

|

250

|

2.5

|

9000

|

|

RT2-280-9

|

3000×1500×900

|

280

|

2.5

|

10000

|

|

RT2-300-9

|

3000×1530×950

|

300

|

2.5

|

11000

|

|

RT2-320-9

|

3200×1530×950

|

320

|

2.5

|

12000

|

|

RT2-350-9

|

3500×1500×1200

|

350

|

2.5

|

15000

|

|

RT2-380-9

|

4000×1500×1200

|

380

|

2.5

|

18000

|

|

RT2-400-9

|

4500×1500×1200

|

400

|

3

|

20000

|

|

RT2-420-9

|

4500×1600×1200

|

420

|

3

|

22000

|

|

RT2-450-9

|

5200×1500×1200

|

450

|

3

|

25000

|

|

RT2-480-9

|

5500×1500×1200

|

480

|

3

|

28000

|

|

RT2-500-9

|

6000×1500×1200

|

500

|

3

|

30000

|

|

RT2-540-9

|

6500×1800×1200

|

540

|

3

|

35000

|

|

RT2-600-9

|

7000×1800×1200

|

600

|

3

|

38000

|

|

RT2-650-9

|

7200×2000×1200

|

650

|

3

|

40000

|

|

RT2-700-9

|

7500×1800×1800

|

700

|

3

|

42000

|

|

RT2-800-9

|

8500×2000×1500

|

800

|

3.5

|

52000

|

|

RT2-900-9

|

9000×2200×1600

|

900

|

3.5

|

60000

|