NaN / 0

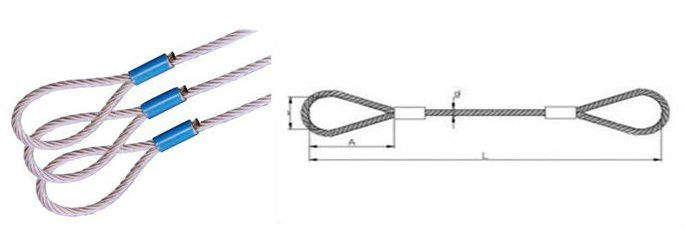

PVC Coated Wire Rope Assembly Security Cable Lock With Loop Ends

Get Latest Price

US$ 0.8

≥2000 Pieces

Quick Details

Steel Grade:

60#

Type:

galvanized

Tolerance:

±3%

Grade:

steel and PVC

Product Details

PVC Coated Wire Rope Assembly Security Cable Lock With Loop Ends

|

Rope Construction |

7 x 7 |

|

Diameter |

5mm |

|

Length |

per the customer's requirement |

|

End Fittings |

ferrule secured or per the customer's requirement |

|

Place of Origin |

Jiangsu,China (Mainland) |

|

Brand Name |

Gaosheng |

|

Packaging Details |

As for small diameter,they will be packed by carton boxes and then packed by pallets; as for large diameter,we will pack them by crates directly. |

|

Payment Terms |

L/C,T/T |

We can manufacture many kinds of wire rope sling. Swaged Soft Eye Sling, Spliced Soft Eye Slings, Endless Wire Rope Slings, Single-leg Swaged Sling Assemble, Eye and eye with heavy thimbles and so on.

1. Min breaking load is 6 times WLL

2. aluminum sleeve secured

3. Surface treatment: electric galvanized or Black with the oil

4. Fully in line with European standards EN 13411-3

5. Specification of the steel wire rope: 6 X 19+FC/6 X 19+IWR/6X37+FC/6X37+IWR

6. Diameter: Ø5-30mm

7. Color: clear, black with the oil

8. Length: As requirements

9. Type: one end free + one end eye; both of end eye; with thimbles; without thimbles

10. The feature is soft, high strength, easy to use, and it is special for the limited rooms work and large lifting project.

11. Quality and safety assurance

We Supply wire rope slings according to your drawing or samples

Steel Wire Rope Sling is made by the best quality steel wire rope and produced with the most professional equipments and techniques. It is widely used in the field of machinery, mining, metallurgy, construction, shipping yard, bridge project, gymnasium, oil field etc.

Advantages:

1. The technology will increase the intensity of the hand-made rope and the aggregate breaking force is increased from 70% to 95%.

2. Length, specification, construction are determined by the customer, and the central length of the free file is for reference, we can make the production according to the customer's requirement.

3. Add thimbles, heavy thimbles to extend the useful life, and to make the configuration more reasonable.

4. The safety factor is determined by the work condition, usually 4 to 6, and the applicable environment temperature is -40°C ~ 150°C.

5. It should be disused when the joint is cracked, deformed, corroded or the diameter has reduced to less than 95%.