NaN / 0

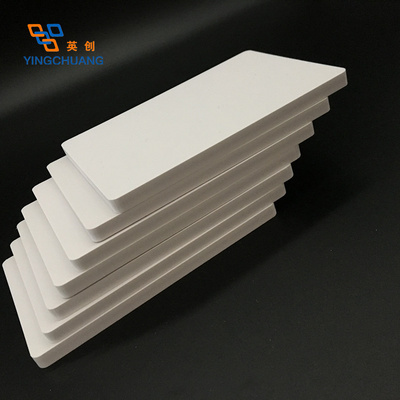

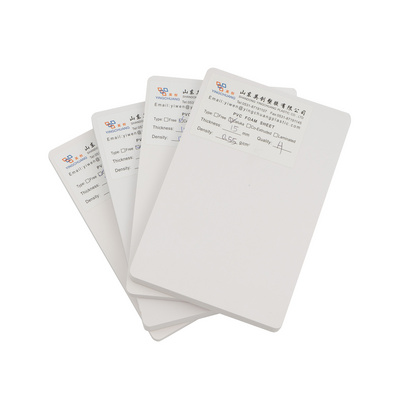

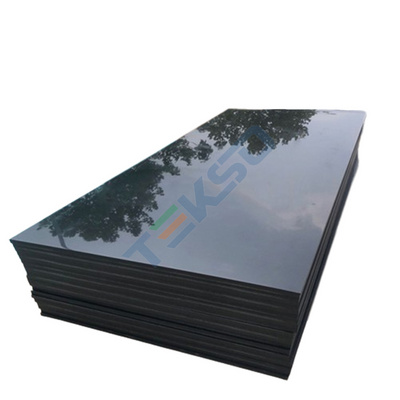

1220 x 2440 x 7mm PVC Celuka Foam Board (48\" x 96\") Plastic Sheets for Advertising and Sculpture

Get Latest Price

US$ 6.78

≥50 Pieces

US$ 6.5

≥100 Pieces

US$ 6.36

≥500 Pieces

Quick Details

Processing Service:

Cutting

Place of Origin:

Guangdong, China

Brand Name:

YATUSI

Thickness:

1-30mm

Product Details

1:Introduction

PVC foam board is becoming the substitution of wood in many fields such as AD and Decoration. Itmade through foaming and pressing into shape with additives. The main material is PVC.So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

2:Processing performance

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

3:Applications

1, exhibition desk, Shelve in supermarket;

2, Advertisement Board and sign board.;

3, Architectural decoration and upholstery;

4, Printing,Engraving,Furniture,Bathroom cabinet;

5, decoration for partition wall and shopwindows.

4:Features

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Hot Searches