NaN / 0

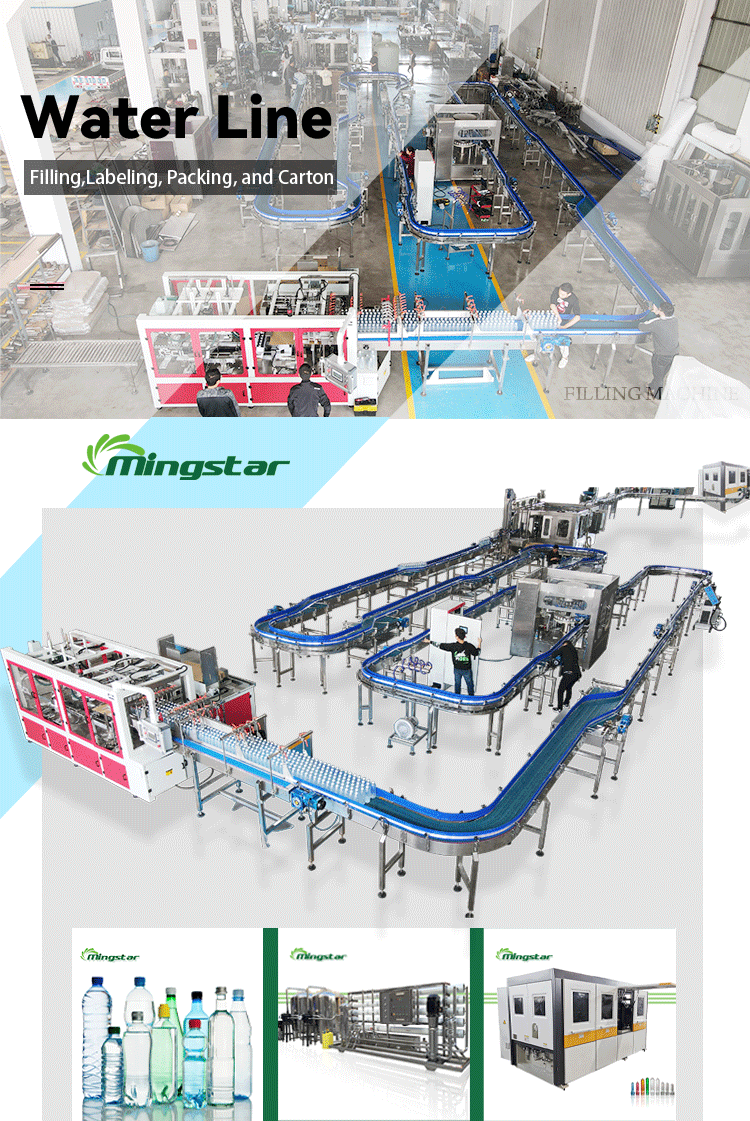

Mingstar 3000 BPH Automatic mineral drinking pure water bottling plant machine equipment bottle filling machine price in ghana

Get Latest Price

US$ 11000

≥1 Pieces

US$ 9999

≥20 Pieces

US$ 8999

≥30 Pieces

US$ 5999

≥40 Pieces

Quick Details

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

Packaging Material:

Plastic

Filling Material:

Water

Filling Accuracy:

2ml

Product Details

Bottle Water Water Treatment System Bottle Blowing Machine

Water Filling Machine Labeling Machine Carton Wrapping Machine

|

Normal

|

CGF8-8-3

|

CGF-14-12-5

|

CGF-16-16-6

|

CGF24-24-6

|

CGF32-32-8

|

CGF 40-40-10

|

|

Production capacity(bottles per hour for 500ml)

|

3000 BPH

|

5000BPH

|

8000BPH

|

12000BPH

|

15000BPH

|

18000BPH

|

|

Washing heads

|

8

|

14

|

16

|

24

|

32

|

40

|

|

Filling heads

|

8

|

12

|

16

|

24

|

32

|

40

|

|

Capping heads

|

3

|

5

|

6

|

6

|

8

|

10

|

|

Weight

|

2000KG

|

2000KG

|

4000KG

|

4500KG

|

6000KG

|

7800KG

|

|

Main motor power

|

1.5KW

|

1.5KW

|

3KW

|

3KW

|

3KW

|

5.5KW

|

GOOD QUALITY COMES FROM DETAILS

We are confident about our product quality because of the Quality Assurance System

backed by technical capabilities and production

capacity. We believe “all steps in production are quality control processes”.

01 - Air Conveyor

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

- Rack made by high quality carbon steel welded.

02 - Washing Parts

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

03 - Filling Parts

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

04 - Capping Parts

- Place and capping system, electromagnetic capping heads, with burden discharge function,

make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

05 - Flat Conveyor

- Energy saving. High efficient. Adapt to customer factory layout

- Special lubrication system, keep products clean, health, safety

- Extended service life

- Electric eyes design keep whole line running safety and quickly

- Overload protection mechanism to effectively ensure the safety of the machine

WATER LINE EQUIPMENT

We are confident about our product quality because of the Quality Assurance System

backed

by technical capabilities and production capacity.

We believe “all steps in production are quality control processes”

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

02 - Blow Molding Machine

High capacity: 4000-6000bph for 4 molds servo control

Flexibility: 200ml to 2000ml adapted

Stability: 10 years working properly

Easy to operate

Easy to maintain

Easy to change mold

FESTO cylinder / NSK bearing / Siemens PLC

Siemens inverter / Sick sensor

03 - Label Labeling Machine

Boasting four carousel sizes, up to three labelling stations and 24 configurations,

can generate outputs of up to 72,000 containers per hour, when standalone, at an

efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

04-Carton Wrapping machine

High capacity: up to 20-25 package/minute

Flexibility: 2x3 3x4 4x6 5x6 6x8 adapted

Stability: 10 years working properly

Suitable for: PET, PP, Glass bottles, Can

Carton adopted: Corrugated paper

Easy to operate

Easy to maintain

Easy to adjust

OMRON PLC / ATAN inverter

/ AIRTAC cylinder / AUIONICS sensor

FAQ

Q:HOW TO ENSURE THE QUALITY OF FILLING MACHINE?

※In order to ensure the accuracy of each part, we are equipped with a variety of professional processing

equipment.

※Each component before assembly needs strictly control by inspecting personnel.

※Each assembly is in charged by a master who has working experience for more than 6 years.

※After all the machines are completed, we will connect them together and run the full production line

for at least 12 hours to ensure the stable running in clients' factory.

※We offer whole filling line testing production service in our factory for hours by request.

Q: WHAT WARRANTY OF FILLING MACHINE CAN I GET FROM MINGSTAR?

※Two years warranty after receiving the equipment . Free spare parts and technical supports.

※New client guarantee programme offers longer warranty and customized after service.

※Local after service network is under construction.

※Annual engineer visiting for diagnosis and updating service.

Q: Any OTHER QUESTION?

※Send inquiry to Mingstar.

※Chat now through Alibaba APP.

※Call us or reserve a call.

Hot Searches