NaN / 0

burnt clay brick tile making machine making fully automatic brick production line

Get Latest Price

US$ 8000

≥1 Sets

Quick Details

Type:

non vacuum

Brick Raw Material:

Clay

Production Capacity (Pieces/8 hours):

2000pcs/h

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

Product Details

Tile making step:

Step 1: Using vacuum extruder to extruding the mud column

Step 2: Pressing the mud slice into a tile with a tile pressing machine

Step 3: After pressing.tiles need to dry in natural

Step 4: After drying.tiles need to fire

| How to choose Tile pressing machine |

1. manual machine

2.electric machine

3.Hydraulic machine

Advantages

1.This machine can produce clay bricks and tiles ,you only need to change mold;

2.Easy operation;

3.Energy and labor saving;

4.Small investment;

5. This model is hot sale in Burma, Neple .India.Bangladesh and South Afria etc.

| Related Products |

|

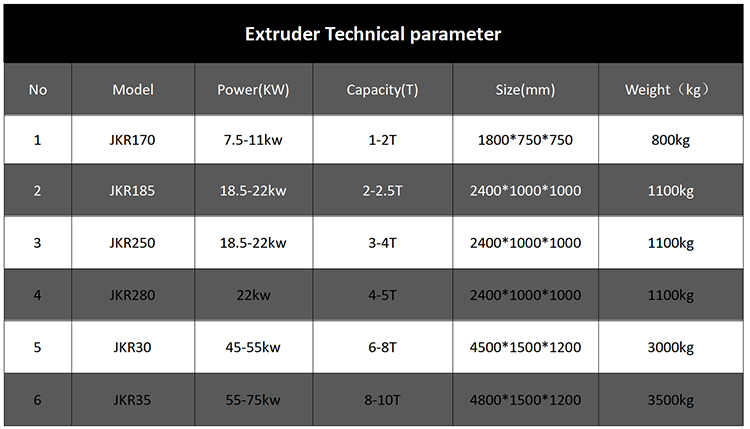

clay tile extruder |

electric tile pressing machine |

manual tile making machine |

|

JKR28 clay brick extruder |

b ig capacity brick machine |

|

Hot Searches